Method for preparing carbon nanotube reinforced magnesium-based composites of layered structure

A carbon nanotube and composite material technology, which is applied in coatings, electrolytic coatings, electrophoretic plating, etc., can solve the problem that the strength and plasticity of pure magnesium matrix cannot be balanced, and achieve the effects of improving mechanical properties, increasing strength and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

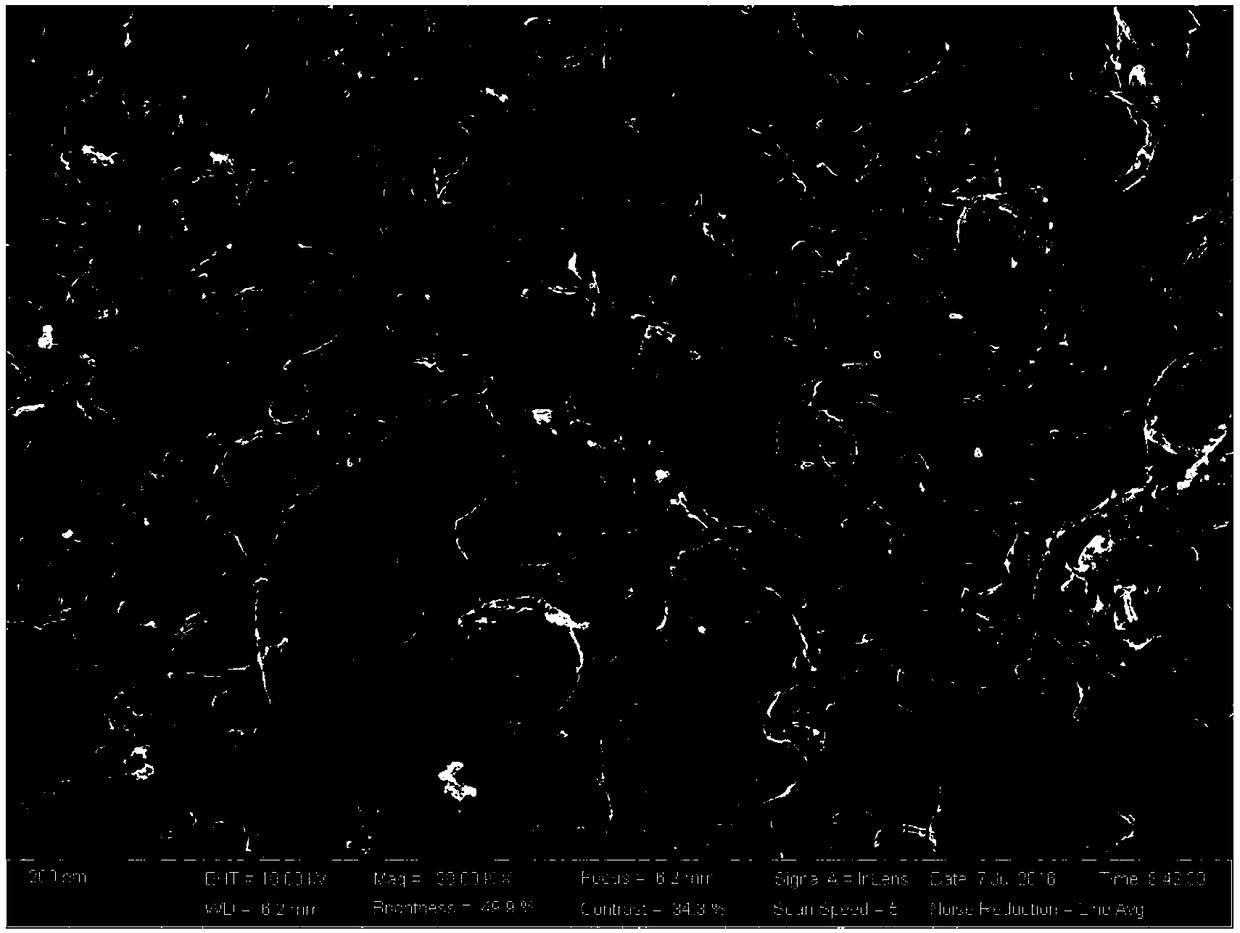

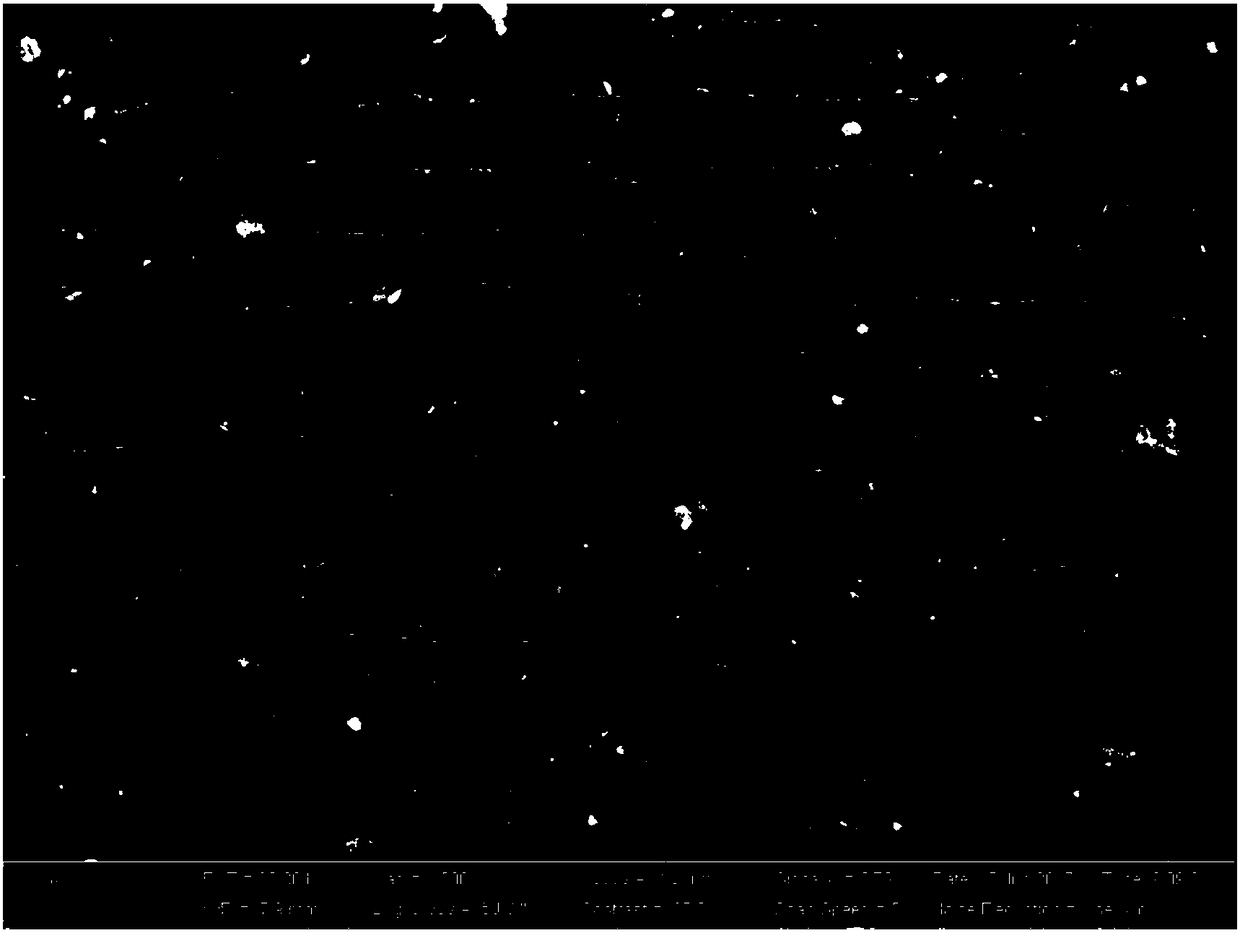

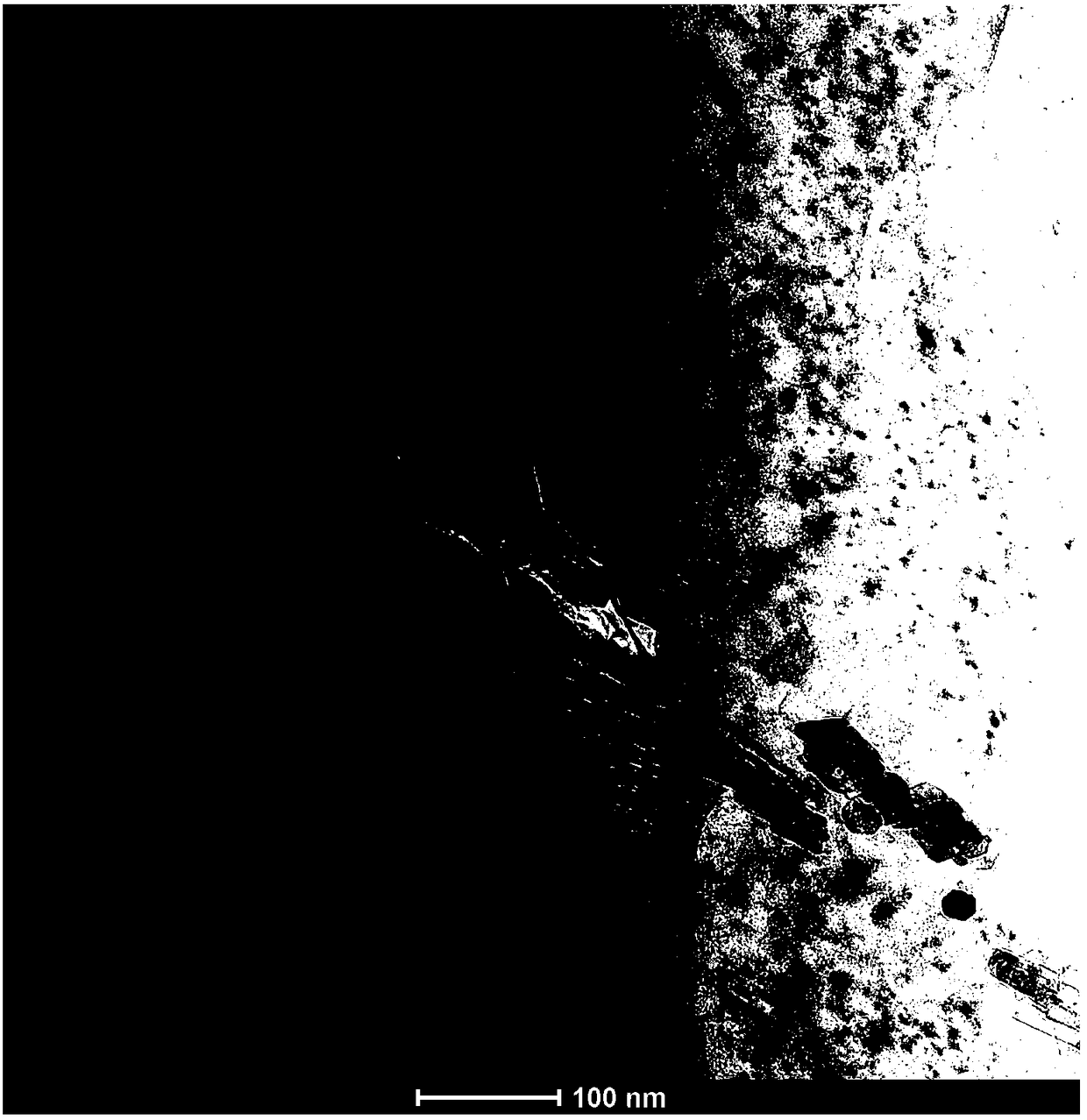

[0022] Embodiment 1: A method for preparing a carbon nanotube-reinforced magnesium-based composite material with a layered structure in this embodiment is completed by the following steps:

[0023] Step 1. Grind the magnesium foil with 2000# sandpaper on the pre-grinder, remove the oxide on the surface of the magnesium foil as the cathode, use the stainless steel plate as the anode, immerse the cathode and the anode in the electrophoretic solution together, and conduct the process under a constant voltage of 20V. Electrophoretic deposition for 90s, carbon nanotubes adsorb Al during electrophoretic deposition 3+ Afterwards, it bears a positive charge, moves towards the magnesium foil under the action of an electric field, and then deposits on the magnesium foil, and then puts it in a vacuum drying oven and dries it at 80°C to obtain a carbon nanotube / magnesium layered unit ;

[0024] Step 2. Stack 50 carbon nanotubes / magnesium layered elements obtained in step 1 layer by layer...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 2, vacuum hot pressing is sintered at 500° C. and a pressure of 55 MPa, and the sintering time is 7 hours. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 2, vacuum hot-pressing sintering is carried out at 630° C. and a pressure of 30 MPa, and the sintering time is 5 hours. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com