Oxide dispersion strengthened (ODS) high-entropy alloy and preparation method thereof

A high-entropy alloy and dispersion strengthening technology, which is applied in the field of metal structural materials, can solve the problems of exogenous ODS high-entropy alloys, such as low yield strength and poor plasticity, and achieve wide composition range, wide preparation conditions and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

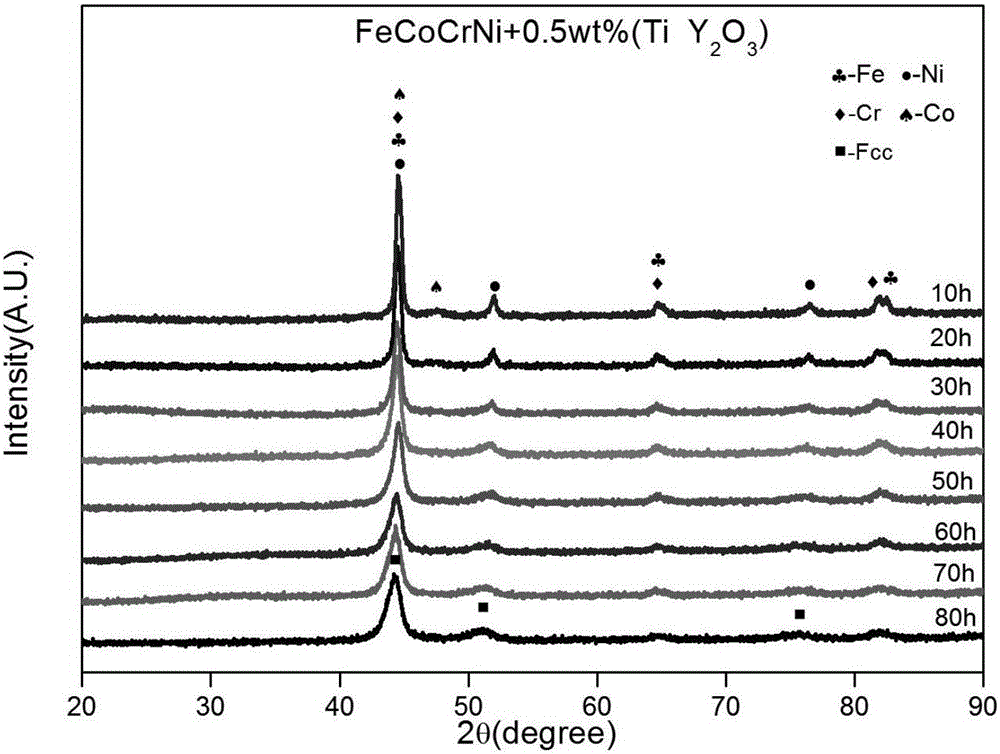

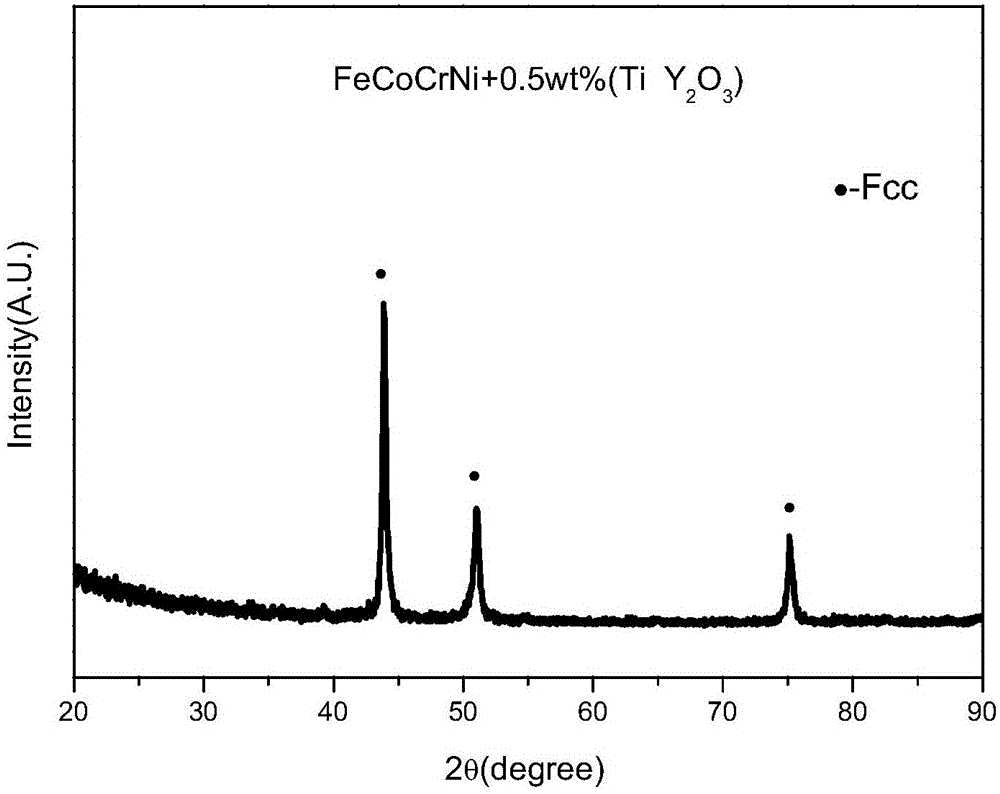

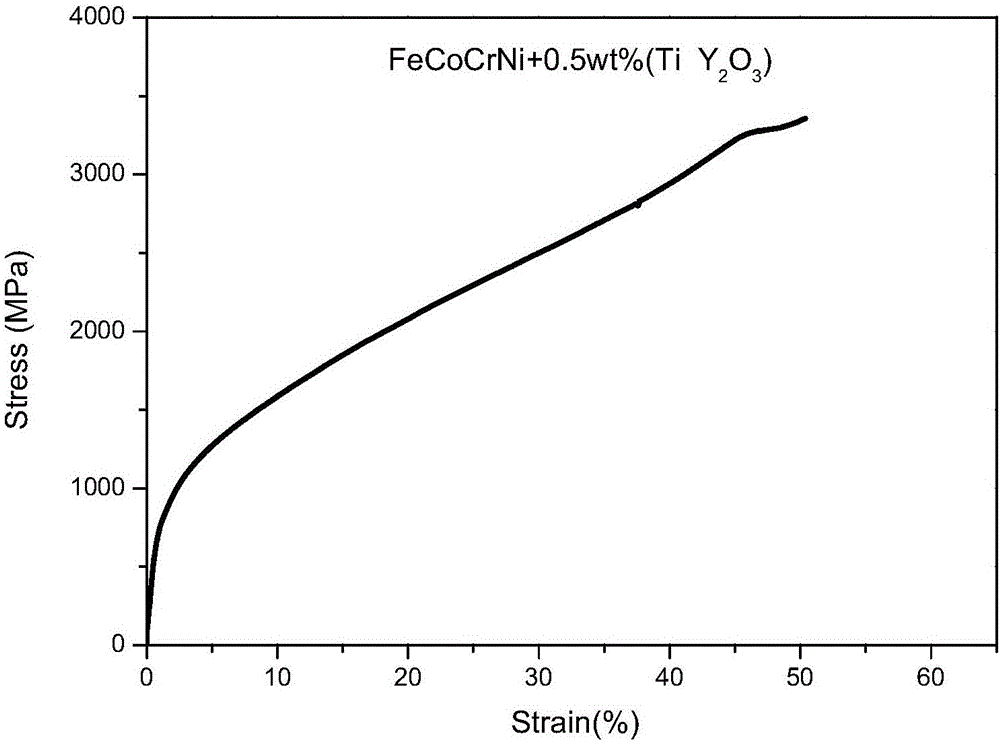

[0049] FeCoNiCr added 0.5wt% (Ti, Y 2 o 3 ) Preparation and Properties of High Entropy Alloys

[0050] (1) Ingredient distribution ratio: The raw materials used in the experiment are matrix element powder (composition is FeCoNiCr) and titanium powder and nano Y 2 o 3 Powder, the purity is higher than 99.9wt%. Among them, the particle size of matrix element powder and titanium powder is 200-325 mesh, Y 2 o 3 The average particle diameter of the powder was 30 nm. Convert the high-entropy alloy components of the equiatomic ratio into mass percentage, and then according to the mass percentage, it is 99.5(FeCoNiCr)-0.33Ti-0.17Y 2 o 3 Weigh and mix separately.

[0051] (2) High-energy ball milling: put the powder together with 300 g of stainless steel balls into a vacuum ball milling tank, and operate in a vacuum glove box in an argon atmosphere. An omnidirectional planetary ball mill was used for ball milling, the ball milling process was carried out under the protection o...

Embodiment 2

[0055] FeCoNiCrAl added 0.5wt% (Ti, Y 2 o 3 ) Preparation and Properties of High Entropy Alloys

[0056] (1) Ingredient distribution ratio: The raw materials used in the experiment are matrix element powder (composition is FeCoNiCrAl) and titanium powder and nano Y 2 o 3 Powder, the purity is higher than 99.9wt%. Among them, the particle size of matrix element powder and titanium powder is 200-325 mesh, Y 2 o 3 The average particle diameter of the powder was 30 nm. Convert the high-entropy alloy components of the equiatomic ratio into mass percentage, and then according to the mass percentage, it is (FeCoNiCrAl)-0.33Ti-0.17Y 2 o 3 Weigh and mix separately.

[0057] (2) High-energy ball milling: put the powder together with 300 g of stainless steel balls into a vacuum ball milling tank, and operate in a vacuum glove box in an argon atmosphere. An omnidirectional planetary ball mill was used for ball milling, the ball milling process was carried out under the protection...

Embodiment 3

[0060] Embodiment 3: FeCoNiCr adds 1wt% (Ti, Y 2 o 3 ) Preparation and Properties of High Entropy Alloys

[0061] (1) Ingredient distribution ratio: The raw materials used in the experiment are matrix element powder (composition is FeCoNiCr) and titanium powder and nano Y 2 o 3 Powder, the purity is higher than 99.9wt%. Among them, the particle size of matrix element powder and titanium powder is 200-325 mesh, Y 2 o 3 The average particle diameter of the powder was 30 nm. Convert the high-entropy alloy components of the equiatomic ratio into mass percentage, and then according to the mass percentage, it is (FeCoNiCr)-0.67Ti-0.33Y 2 o 3 Weigh and mix separately.

[0062] (2) High-energy ball milling: put the powder together with 300 g of stainless steel balls into a vacuum ball milling tank, and operate in a vacuum glove box in an argon atmosphere. An omnidirectional planetary ball mill was used for ball milling, the ball milling process was carried out under the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com