A kind of nanocomposite oxide dispersion strengthened molybdenum alloy and preparation method thereof

A composite oxide and dispersion strengthening technology, applied in the direction of reducing greenhouse gases, nuclear power generation, climate sustainability, etc., can solve the problems of large oxide size, grain boundary segregation of oxygen elements, etc., to improve oxygen content, increase strength, Effect of improving high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

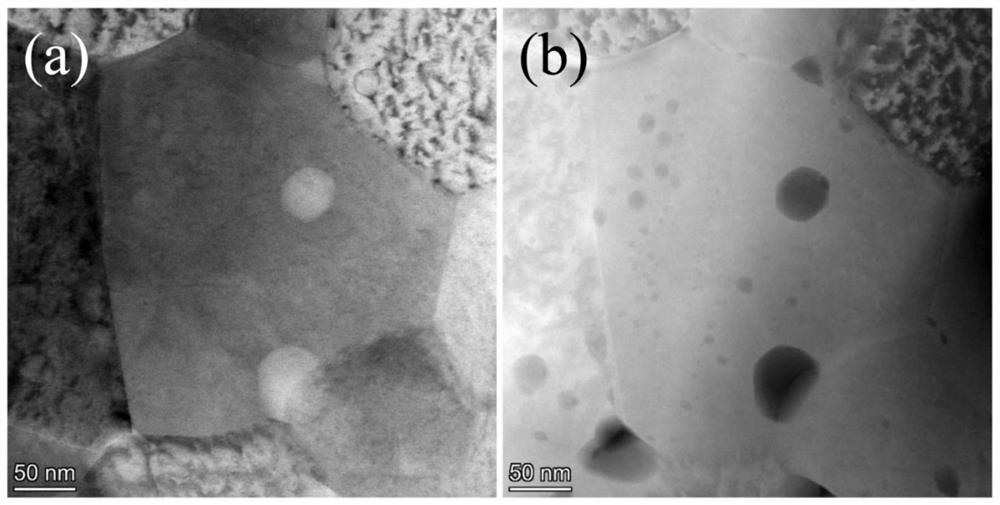

Image

Examples

Embodiment 1

[0026] The nanocomposite oxide dispersion-strengthened molybdenum alloy of this embodiment has a composition ratio of 1% Y in terms of mass fraction. 2 O 3 , 0.6% Zr, the remainder is molybdenum and inevitable impurities.

[0027] The preparation method of the nanocomposite oxide dispersion-strengthened molybdenum alloy of the present embodiment is:

[0028] 1) Molybdenum metal element powder, Y 2 O 3 Powder and Mo 2 Zr alloy element powder, weighed according to the composition ratio, and then put into a 250mL zirconia ball mill jar together with a 10mm diameter grinding ball, and the material-to-ball ratio is 1:10. Perform powder mixing and encapsulation.

[0029] 2) In a high-purity argon atmosphere, the mixed powder was ball-milled at a speed of 300 rad / min for 30 hours. In order to avoid powder agglomeration caused by overheating, every 2 hours of operation, the machine was stopped for 1 hour and reversed once. 2 O 3 Solid solution with Zr in molybdenum matrix to pr...

Embodiment 2

[0033] The nanocomposite oxide dispersion-strengthened molybdenum alloy of this embodiment has a composition ratio of 2% Y in terms of mass fraction. 2 O 3 , 0.6% Zr, the remainder is molybdenum and inevitable impurities.

[0034] The preparation method of the nanocomposite oxide dispersion-strengthened molybdenum alloy of the present embodiment is:

[0035] 1) Molybdenum metal element powder, Y 2 O 3 Powder and Mo 2 Zr alloy element powder, weighed according to the composition ratio, and then put into a 250mL zirconia ball mill jar together with a 10mm diameter grinding ball, and the material-to-ball ratio is 1:10. Perform powder mixing and encapsulation.

[0036]2) In a high-purity argon atmosphere, the mixed powder was ball-milled at a speed of 200 rad / min for 48 hours. In order to avoid powder agglomeration caused by overheating, every 2 hours of operation, the machine was stopped for 1 hour and reversed once, and circulated in turn. Y is processed by high energy bal...

Embodiment 3

[0040] The nanocomposite oxide dispersion-strengthened molybdenum alloy of this embodiment has a composition ratio of 1% Y in terms of mass fraction. 2 O 3 , 1.2% Zr, the remainder is molybdenum and inevitable impurities.

[0041] The preparation method of the nanocomposite oxide dispersion-strengthened molybdenum alloy of the present embodiment is:

[0042] 1) Molybdenum metal element powder, Y 2 O 3 Powder and Mo 2 Zr alloy element powder, weighed according to the composition ratio, and then put into a 250mL zirconia ball mill jar together with a 10mm diameter grinding ball, and the material-to-ball ratio is 1:10. Perform powder mixing and encapsulation.

[0043] 2) In a high-purity argon atmosphere, the mixed powder was ball-milled at a speed of 400 rad / min for 12 hours. In order to avoid powder agglomeration caused by overheating, every 2 hours of operation, the machine was stopped for 1 hour and reversed once, and circulated in turn. Y is processed by high energy ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com