Double-scale ceramic particle hybrid high-elastic modulus high-strength aluminum alloy and preparing method thereof

A technology of ceramic particles and aluminum alloy, which is applied in the field of high-performance aluminum alloy processing and its preparation, can solve the problems of damage to the plasticity of materials, and achieve the effects of cost saving, good interface bonding and important economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

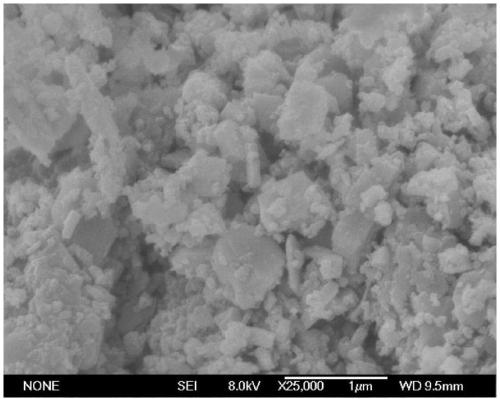

[0042] The present invention also provides a method for preparing a high-elastic-modulus high-strength aluminum alloy mixed with dual-scale ceramic particles, comprising the following steps:

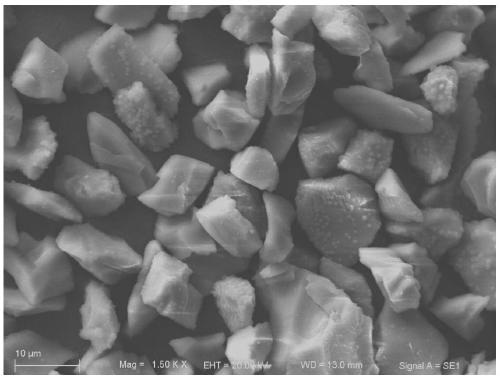

[0043] Step 1. Pretreatment of Micron SiC Ceramic Particles

[0044] (1) SiC surface oxidation treatment

[0045] i. Spread the SiC powder on a high-purity corundum crucible with a diameter of 100mm and a height of 20mm, with a thickness of about 0.3-0.8mm, and then put the corundum crucible into a high-temperature box-type resistance furnace for calcining, using a segmented oxidation method High temperature oxidation treatment of SiC;

[0046] The specific staged oxidation process is as follows:

[0047] Heat up to 573K at a rate of 20-100K / min, hold for 10 minutes, continue to heat up to 973K at a rate of 20-100K / min, hold for 10 minutes, then heat to a predetermined temperature of 973-1373K, and hold for 1-12 hours.

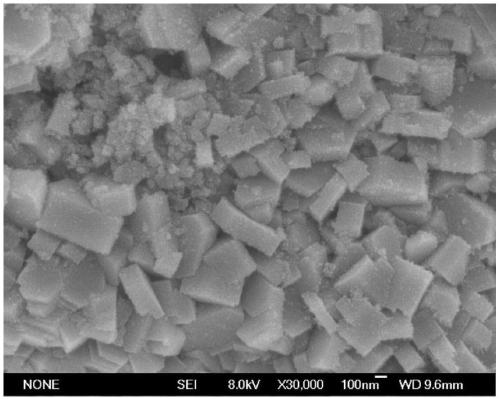

[0048] (2) Ball milling pre-dispersion treatment

[0049] i. ge...

Embodiment 1

[0080] The preparation method of this example comprises the following steps:

[0081] Step 1, pretreatment of micron SiC ceramic particles

[0082] (1) SiC surface oxidation treatment:

[0083] i. Spread the SiC powder on a high-purity corundum crucible with a diameter of 100 mm and a height of 20 mm, with a thickness of about 0.5 mm, and then put the corundum crucible into a high-temperature box-type resistance furnace for calcining, and adopt a segmented oxidation method to SiCp Carry out high-temperature oxidation treatment, and the specific staged oxidation process is as follows: heat up to 573K at a rate of 30K / min, hold at 573K for 10 minutes, continue to heat up to 973K at a rate of 50K / min, hold for 10 minutes, then heat to a predetermined temperature of 1373K, and hold for 2 hours.

[0084] (2) Ball milling pre-dispersion treatment:

[0085] i. Take SiC powder with a particle size of 10 μm and Al-Si-Mg (Si: 7wt.%, Mg: 0.7wt.%, the balance is aluminum) alloy powder w...

Embodiment 2

[0116] Step 1, the pretreatment of micron SiC ceramic particles is as follows:

[0117] (1) SiC surface oxidation treatment:

[0118] i. Spread the SiC powder on a high-purity corundum crucible with a diameter of 100 mm and a height of 20 mm, with a thickness of about 0.8 mm, and then put the corundum crucible into a high-temperature box-type resistance furnace for calcining, and adopt a segmented oxidation method to SiC Carry out high-temperature oxidation treatment, the specific staged oxidation process is as follows: heat up to 573K at a rate of 50K / min, hold at 573K for 10 minutes, continue to heat up to 973K at a rate of 60K / min, hold for 10 minutes, then heat to a predetermined temperature of 1273K, and hold for 5 hours.

[0119] (2) Ball milling pre-dispersion treatment:

[0120] i. Take SiC powder with a particle size of 6 μm and Al-Si-Mg (Si: 9wt.%, Mg: 0.5wt.%, the balance is aluminum) alloy powder with a particle size of 15 μm, according to SiC and Al-Si-Mg alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com