Preparation method of bidirectional perpendicular controlled-rolling trace TiC reinforced Al-Cu-Mg alloy plate

A technology of al-cu-mg and alloy plates, which is applied in the field of preparation of Al-Cu-Mg alloy plates reinforced by micro-amount of TiC in two-way vertical controlled rolling, can solve the problems of poor strengthening effect of ceramic particles, difficulty in particle uniform dispersion and interface bonding, etc. Achieve the effect of grain refinement, density improvement, room temperature tensile strength and yield strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing an Al-Cu-Mg alloy plate reinforced by bidirectional vertical controlled rolling with a small amount of TiC, comprising the following steps:

[0041] Step 1, endogenous method prepares TiC-Al master alloy, specifically as follows:

[0042] (1) Preparation of Al-Ti-C system reaction compact

[0043] (a) Weigh Ti powder, carbon nanotube powder (CNT) and aluminum alloy powder according to the mass ratio of 12:3:35 for subsequent use;

[0044] Wherein, the composition of the aluminum alloy powder is: Cu: 3.9-4.8%; Mg: 0.40-0.8%; Si: 0.6-1.2%; Zn: ≤0.30%; Mn: 0.40-1.0%; Ti: ≤0.15% ; Ni: ≤0.10%; Fe: 0.000~0.700%, the balance being Al.

[0045] (b) After mixing the Ti powder with carbon nanotube powder (CNT) and aluminum alloy powder, put them into a mixing tank with zirconia grinding balls, and each tank contains a mixture of 5 mm, 7 mm, and 11 mm in diameter. , 15mm, 20mm, 22mm ZrO 2 Balls, 10 of each, ZrO 2 The ball mass is ...

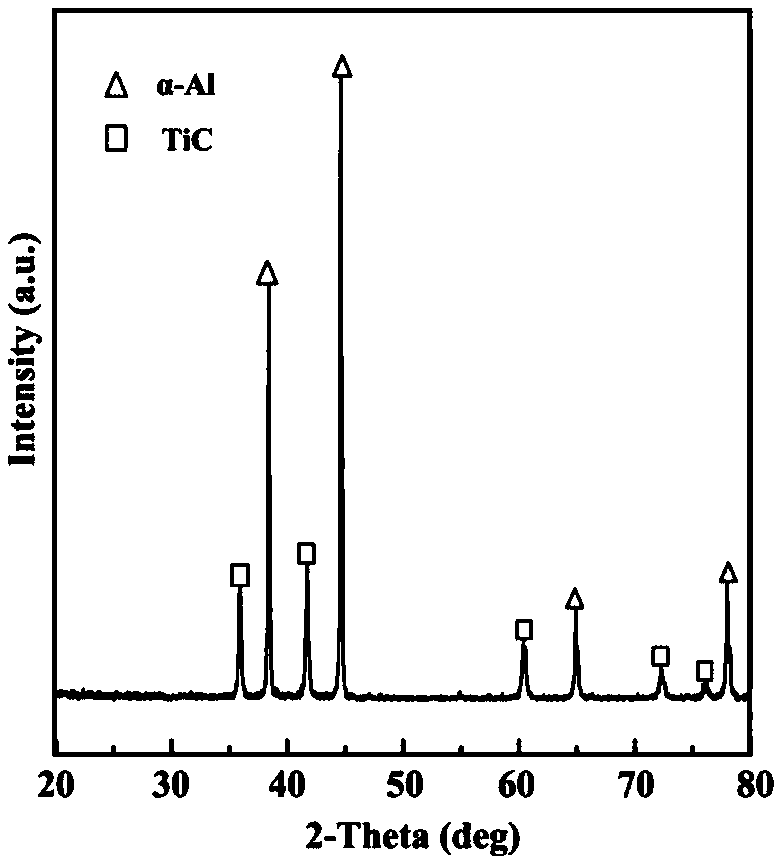

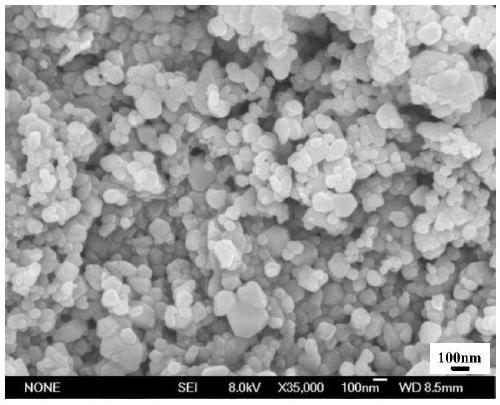

Embodiment 1

[0071] This embodiment is an Al-Cu-Mg alloy rolled plate reinforced by two-way vertical controlled rolling TiC, and the amount of endogenous nano-TiC ceramic particles is 0.1wt.%. The specific method is as follows:

[0072] Step 1, endogenous method prepares TiC-Al master alloy, specifically as follows:

[0073] (1) Preparation of Al-Ti-C system reaction compact

[0074] (a) Weigh 24.000g of Ti powder with a particle size of 15 μm, 6.000g of CNT powder (the molar ratio of Ti powder and CNT powder is 1:1) and 70.000g of aluminum alloy powder for later use;

[0075] Among them, the composition of aluminum alloy powder is: Cu: 4.5%; Mg: 0.7%; Si: 0.6%; Zn: 0.3%; Mn: 0.5%; Ti: 0.1%; Ni: 0.1%; The amount is Al.

[0076] (b) Put 100g of mixed powder and zirconia balls into a mixing tank containing ZrO powders with diameters of 5mm, 7mm, 11mm, 15mm, 20mm and 22mm respectively. 2 Balls, 10 each, ZrO 2 The ball mass is 800g in total, the ball-to-material ratio is set to 8:1, the ba...

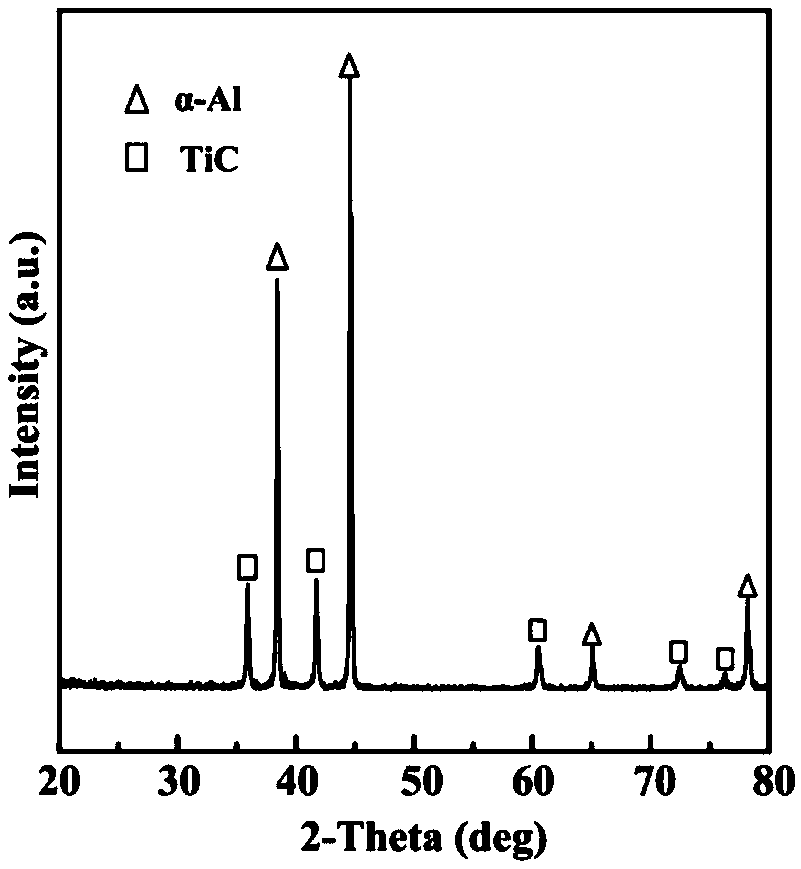

Embodiment 2

[0104] This embodiment is an Al-Cu-Mg alloy rolled plate reinforced by two-way vertical controlled rolling TiC, and the amount of endogenous nano-TiC ceramic particles is 0.3wt.%. The specific method is as follows:

[0105] Step 1, endogenous method prepares TiC-Al master alloy, specifically as follows:

[0106] (1) Preparation of Al-Ti-C system reaction compact

[0107] (a) Weigh 24.000g of 48μm Ti powder, 6.000g of CNT powder (the molar ratio of Ti powder and CNT powder is 1:1) and 70.000g of Al alloy powder for later use; wherein, the composition of the aluminum alloy powder is: Cu: 4.3%; Mg: 0.6%; Si: 0.6%; Zn: 0.15%; Mn: 0.5%; Ti: 0.1%;

[0108] (b) Put 100g of mixed powder and zirconia balls into a mixing tank, which contains ZrO powders with diameters of 5mm, 7mm, 11mm, 15mm, 20mm, and 22mm, respectively. 2 Balls, 10 each, ZrO 2 The ball mass is 800g in total, the ball-to-material ratio is set to 8:1, the ball milling speed of the mixer is set to 60r / min, and the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com