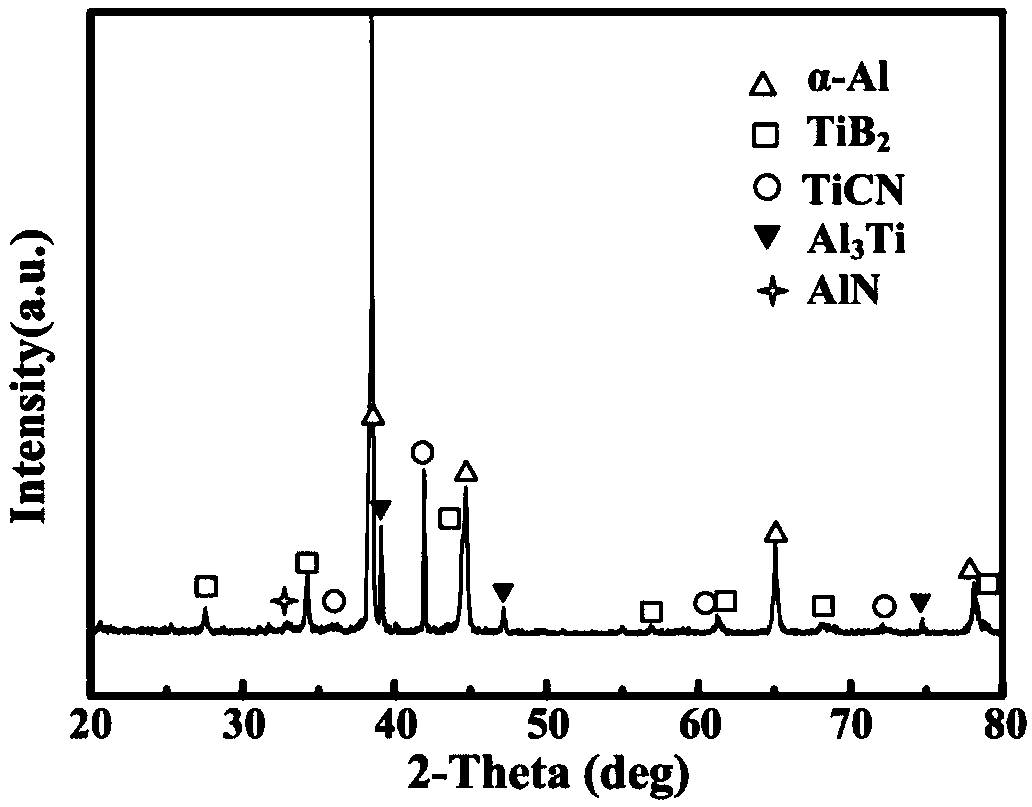

Multi-scale ceramic particle mixed high elastic modulus high strength aluminum alloy and preparation method thereof

A technology of ceramic particles and high elasticity, which is applied in the field of multi-scale ceramic particles mixed with high elastic modulus and high strength aluminum alloy and its preparation, can solve the problems of damaging the plasticity of materials, and achieve the effects of cost saving, uniform dispersion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

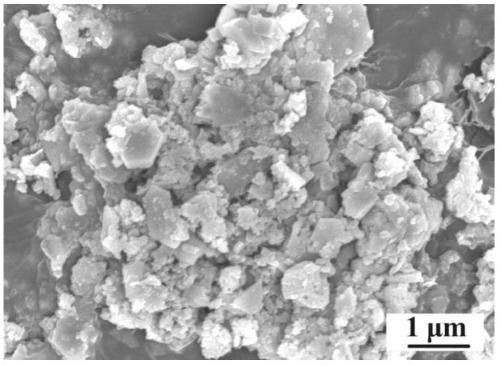

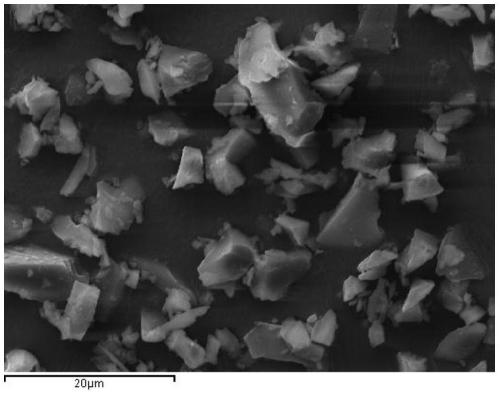

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing multi-scale ceramic particles mixed with high elastic modulus and high strength aluminum alloy, comprising the following steps:

[0045] Step 1. Pretreatment of SiC ceramic particles

[0046] (1) SiC surface oxidation treatment:

[0047] i. Spread the SiC powder on a high-purity corundum crucible with a diameter of 100mm and a height of 20mm, with a thickness of about 0.3-0.8mm, and then put the corundum crucible into a high-temperature box-type resistance furnace for sintering.

[0048] SiC is subjected to high-temperature oxidation treatment by a staged oxidation method. The specific staged oxidation process is as follows: heat up to 573K at a rate of 20-100K / min, keep warm for 10-20min, continue to heat up to 973K at a rate of 20-100K / min, and hold for 5 minutes. -10min, then heat to the predetermined temperature 973K-1373K, keep warm for 1-12h.

[0049] (2) Ball milling pre-dispersion treatment:

[0050] ...

Embodiment 1

[0080] The preparation method of this example comprises the following steps:

[0081] Step 1, the pretreatment of SiC ceramic particle, specifically as follows:

[0082] (1) SiC surface oxidation treatment:

[0083] i. Spread the SiC powder on a high-purity corundum crucible with a diameter of 100 mm and a height of 20 mm, with a thickness of about 0.3 mm, and then put the corundum crucible into a high-temperature box-type resistance furnace for sintering.

[0084] The high temperature oxidation treatment of SiC is carried out by the staged oxidation method. The specific staged oxidation process is as follows: the temperature is raised to 573K at a rate of 20K / min, and the temperature is kept at 573K for 20 minutes, and the temperature is continued to be raised to 973K at a rate of 30K / min. Predetermined temperature 973K, heat preservation 12h.

[0085] (2) Ball milling pre-dispersion treatment:

[0086] i. Take SiC powder with a particle size of 6 μm and Al-Si-Mg (Si: 7%, ...

Embodiment 2

[0115] Step 1, the pretreatment of micron SiC ceramic particles is as follows:

[0116] (1) SiC surface oxidation treatment:

[0117] i. Spread the SiC powder on a high-purity corundum crucible with a diameter of 100 mm and a height of 20 mm, with a thickness of about 0.6 mm, and then put the corundum crucible into a high-temperature box-type resistance furnace for sintering.

[0118] SiC is subjected to high-temperature oxidation treatment by means of staged oxidation. The specific staged oxidation process is as follows: the temperature is raised to 573K at a rate of 50K / min, and the temperature is kept at 573K for 15 minutes. Predetermined temperature 1373K, keep warm for 2h.

[0119] (2) Ball milling pre-dispersion treatment:

[0120] i. Take SiC powder with a particle size of 10 μm and Al-Si-Mg (Si: 8%, Mg: 0.5wt.%, the balance is aluminum) alloy powder with a particle size of 15 μm, according to SiC and Al-Si-Mg alloy powder The mass ratio is 1:3, and it is prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com