Spray-free metal-like color master batch

A metal-like, spray-free technology, applied in the field of color masterbatch, can solve the problems of reducing the production efficiency of enterprises, prolonging the production cycle, high energy consumption, etc., and achieving the effect of shortening the production cycle, reducing the production cost, and strong high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

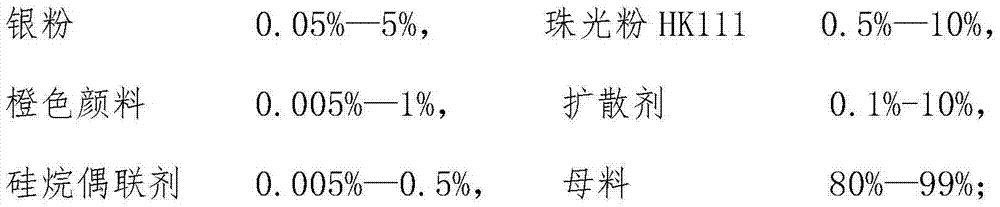

[0022] A spray-free imitation metal color masterbatch, its composition in weight percent:

[0023]

[0024] Described diffusing agent is stearic acid amide and EBS, mixes and prepares by weight 3:1;

[0025] The masterbatch is made by high-speed mixing of PPEPC30R (Maoming Petrochemical) and polypropylene (brand V30G) at a ratio of 1:1 by weight;

[0026] The silane coupling agent is made by high-speed mixing of KH560 and vinyl silane A-171 at a weight ratio of 3:1;

[0027]

[0028]

[0029] The production method is as follows: mix silver powder (less than 600 mesh), pearl powder HK111, orange pigment, diffusing agent, silane coupling agent and masterbatch evenly, extrude and granulate with twin-screw machine to obtain silver imitation metal color masterbatch.

[0030] The silane coupling agent accounts for 0.10%-1.5% of the weight of the silver powder.

Embodiment 2

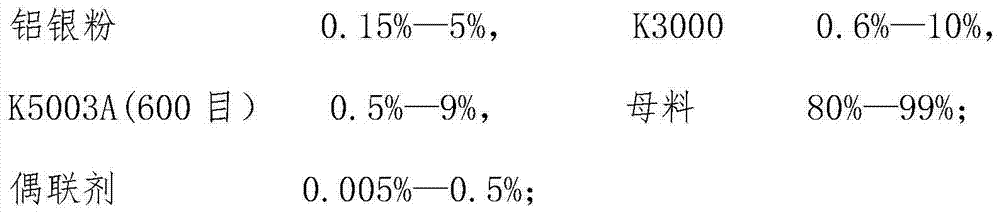

[0032] A spray-free imitation metal color masterbatch, its composition in weight percent:

[0033]

Embodiment 3

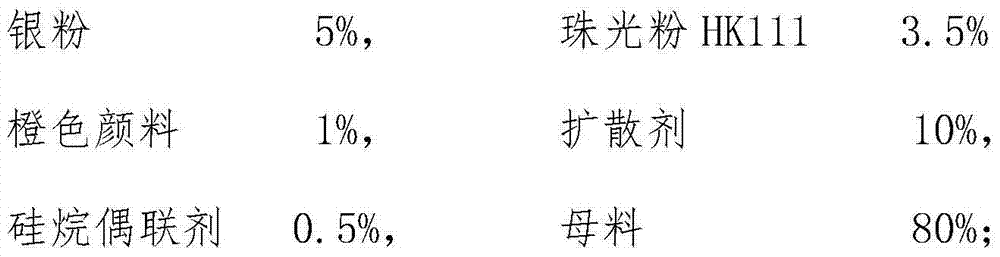

[0035] A spray-free imitation metal color masterbatch, its composition in weight percent:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com