Conductive fiber for pen, preparation method of conductive fiber, capacitive pen and touch device

A technology of conductive fiber and capacitive pen, which is applied in the direction of fiber type, fiber treatment, animal fiber, etc., can solve the problems of excessive rigidity, poor flexibility, strong metal rigidity, etc., achieve mild operating conditions, simple and fast method, and enhanced electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

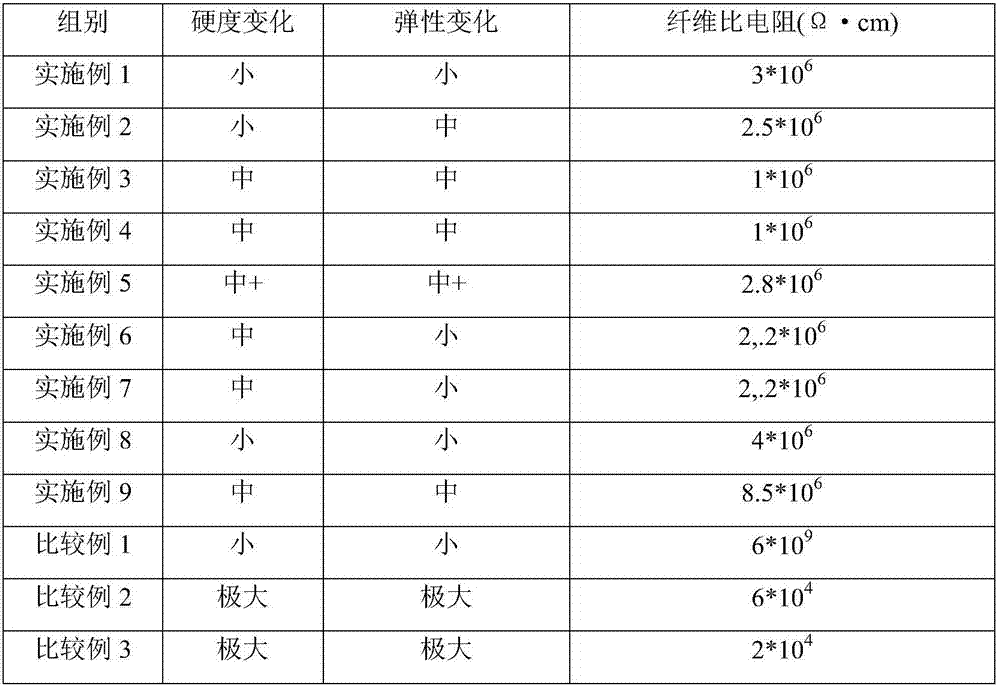

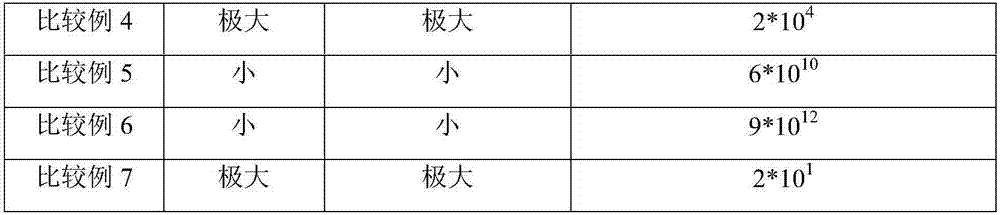

Examples

Embodiment 1

[0056] The specific preparation method of the capacitor brush is as follows:

[0057] 1) Take a hard hair brush, open it in warm water for 20 minutes, remove the glue seal on the surface of the hair, rinse the brush with distilled water, and remove excess water with absorbent paper;

[0058] 2) A graphene oxide solution with a concentration of 0.4 wt% was prepared with distilled water, and ultrasonically treated for 0.5 h. Immerse the entire part of the brush in the graphene oxide solution, and after the part of the pen is completely absorbed by the graphene solution, take it out and let it stand for 10 minutes, then squeeze out the excess graphene solution and dry it at 25-35°C.

[0059] 3) Prepare a 2wt% L-ascorbic acid solution in hot water at 90° C., keep the temperature, and soak the completely dried pen in the solution for 5 hours. After finishing, rinse the brush to remove excess graphene and other impurities, and dry to get a capacitor brush with conductive brush. The...

Embodiment 2

[0061] The specific preparation method of the capacitor brush is as follows:

[0062] 1) Take a woolen brush, open it in warm water for 20 minutes, remove the glue seal on the surface of the hair, rinse the brush with distilled water, and remove excess water with absorbent paper;

[0063] 2) Prepare a weakly oxidized bio-based graphene solution (the particle size of the weakly oxidized bio-based graphene is 800 μm) with a concentration of 0.2 wt% in distilled water, and perform ultrasonic treatment for 1 h. Immerse the entire part of the writing brush in the above-mentioned weakly oxidized bio-based graphene solution for 1-2 hours. After the part of the pen part completely absorbs the graphene solution, take it out and let it stand for 30 minutes, then squeeze out the excess graphene solution, and Dry at 40-50°C.

[0064] 3) Prepare a 4wt% pyrogallic acid solution in hot water at 60° C., keep the temperature, and soak the completely dried pens in the solution for 40 minutes. ...

Embodiment 3

[0066] The specific preparation method of the capacitor brush is as follows:

[0067] 1) Take a soft rabbit hair brush, open it with warm water for 20 minutes, remove the glue seal on the surface of the hair, rinse the brush with distilled water, and remove excess water with absorbent paper;

[0068] 2) Prepare a graphene solution with a concentration of 0.1 wt% (the particle size of the graphene is 10 μm) with distilled water, and perform ultrasonic treatment for 2 hours. Immerse the entire part of the brush in the above graphene solution for 1-2 hours. After the part of the pen part is completely absorbed by the graphene solution, take it out and let it stand for 15 minutes, then squeeze out the excess graphene solution. Let dry.

[0069] 3) Prepare a 1wt% sodium metaphosphate solution in hot water at 70°C, keep the temperature, and soak the completely dried pen in the solution for 20 minutes. After completion, rinse the pen to remove excess graphene and other impurities, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com