Nano silver composite antibacterial material using porous ceramics as carrier and preparation method thereof

A porous ceramic and composite antibacterial technology, applied in the field of antibacterial materials, achieves the effects of less raw material consumption, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

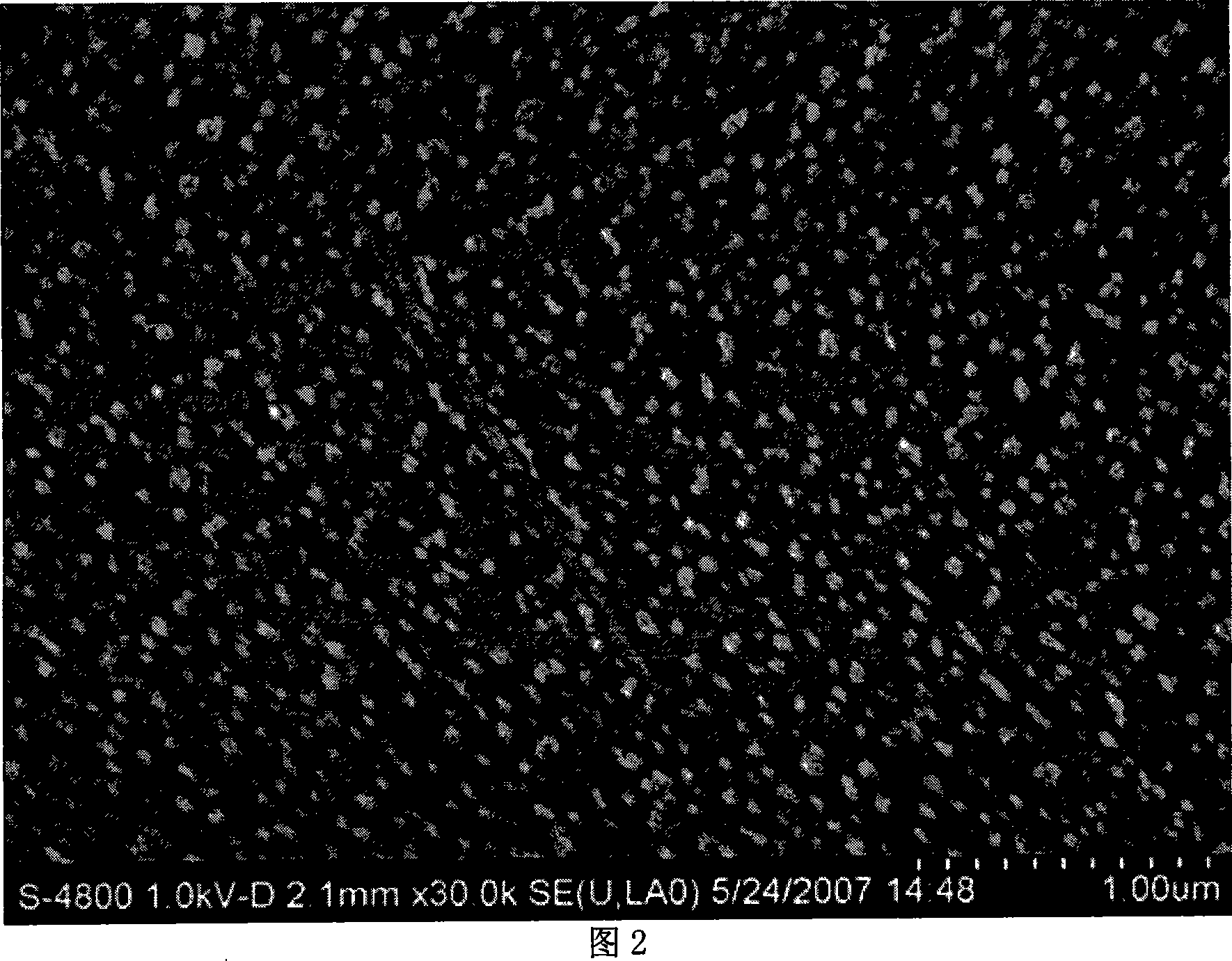

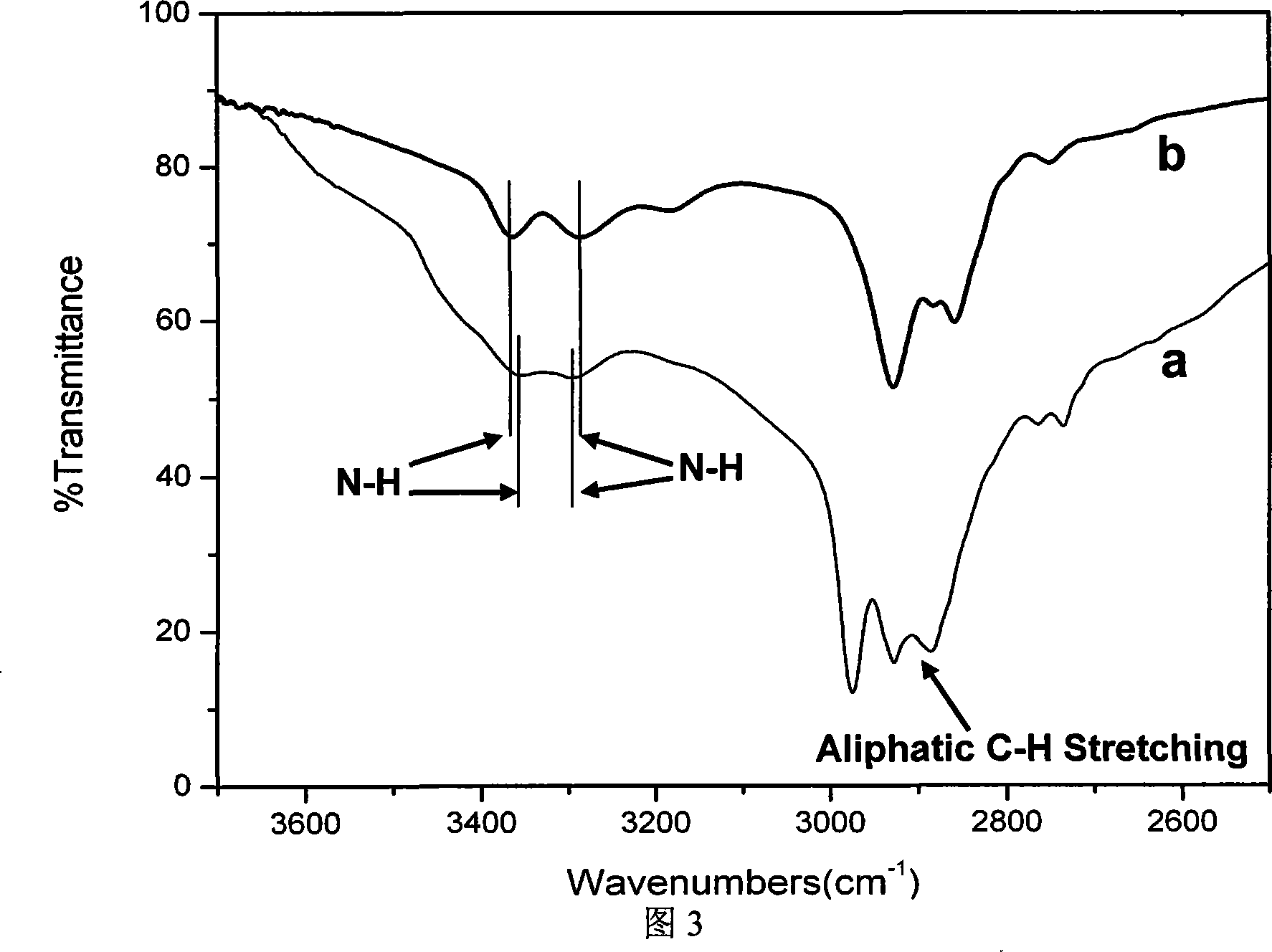

[0032] Embodiment 1: The preparation method of nano-silver composite antibacterial material, wherein the porous ceramics used are purchased from the Filtration Company of Shandong Industrial Ceramics Research and Design Institute. The coupling agent is γ-aminopropyltriethoxysilane (A-1100), and the surfactant is polyvinylpyrrolidone (PVP), and the steps are as follows:

[0033] 1. Add the solid silver nitrate to 10ml of ethylene glycol to dissolve, and stir it magnetically for 10 minutes to prepare a solution of silver nitrate in ethylene glycol, 0.005mol / L;

[0034] 2. Dissolve the surfactant in 10ml of ethylene glycol and stir it magnetically for 10 minutes to prepare a surfactant-based ethylene glycol solution, 0.015mol / L;

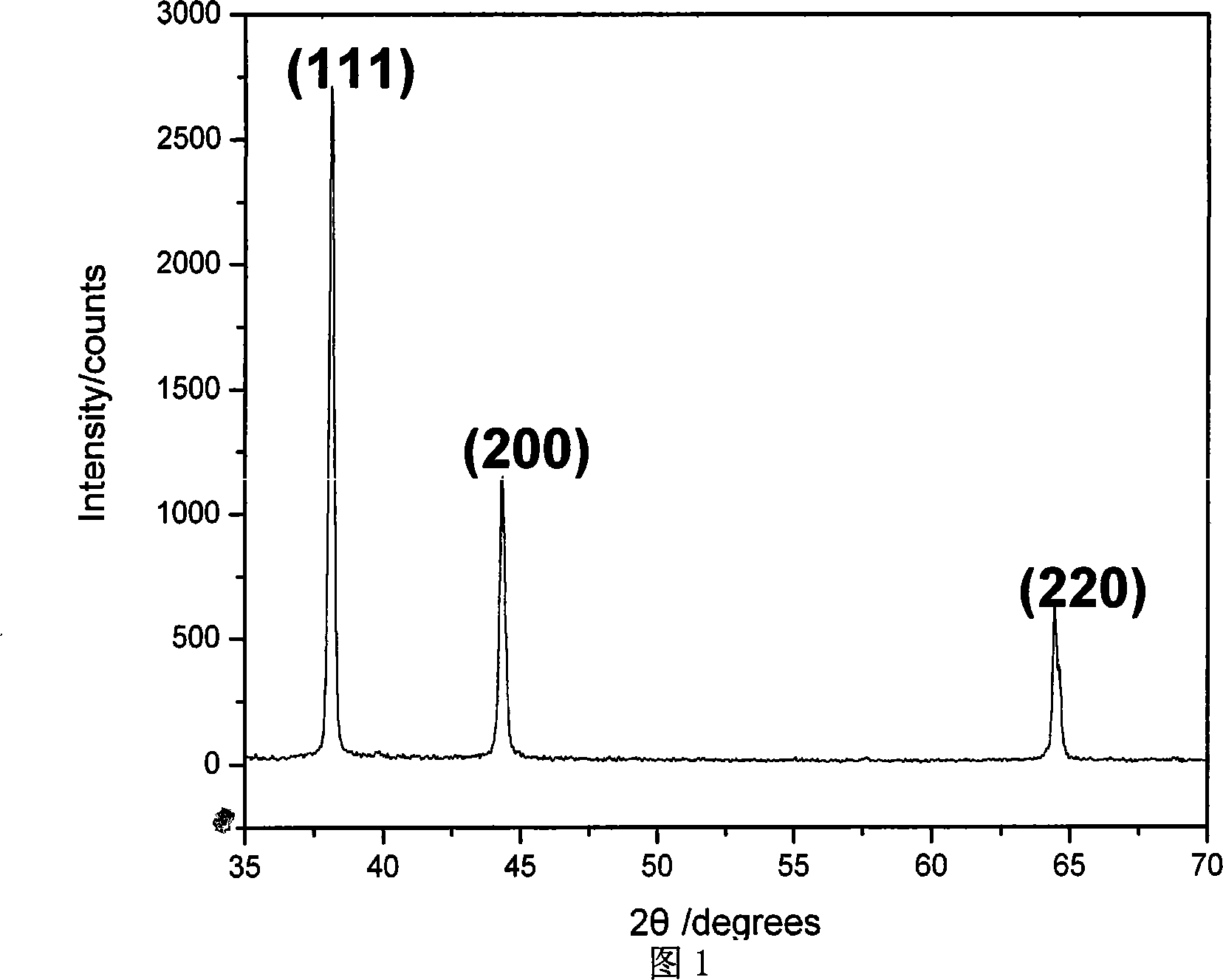

[0035] 3. Mix the two solutions in steps 1 and 2, stir magnetically for 30 minutes, and make nano-silver sol with a particle size of 10-20nm for later use;

[0036] 4. Add the coupling agent to ethanol, mix evenly, prepare a 1% ethanol solution of the ...

Embodiment 2

[0039]Embodiment 2: the preparation method of nano-silver composite antibacterial material, wherein used coupling agent is γ-mercaptopropyltrimethoxysilane (A-189), and surfactant is polyvinylpyrrolidone (PVP), and step is as follows:

[0040] 1. Add the silver nitrate solid into 10ml of ethylene glycol to dissolve, and stir it magnetically for 10 minutes to prepare a solution of silver nitrate in ethylene glycol, 0.02mol / L;

[0041] 2. Dissolve the surfactant in 10ml of ethylene glycol and stir it magnetically for 10 minutes to prepare a surfactant-based ethylene glycol solution, 0.06mol / L;

[0042] 3. Mix the two solutions in steps 1 and 2, stir magnetically for 30 minutes, and make nano-silver sol with a particle size of 40-50nm for later use;

[0043] 4. Add the coupling agent to ethanol, mix evenly, prepare a 1% ethanol solution of the coupling agent by volume, add 0.1% acetic acid by volume based on the ethanol solution of the coupling agent, the pH value is 3.5-5.5, Se...

Embodiment 3

[0046] Embodiment 3: the preparation method of nano-silver composite antibacterial material, wherein used coupling agent is γ-aminopropyltriethoxysilane (A-1100), and surfactant is polyvinylpyrrolidone (PVP), and step is as follows :

[0047] 1. Add the silver nitrate solid into 10ml of ethylene glycol to dissolve, and stir it magnetically for 10 minutes to prepare a solution of silver nitrate in ethylene glycol, 0.04mol / L.

[0048] 2. Dissolve the surfactant in 10ml of ethylene glycol, stir it magnetically for 10 minutes, and prepare the ethylene glycol solution of the surfactant, 0.12mol / L.

[0049] 3. Mix the two solutions in steps 1 and 2, and stir magnetically for 30 minutes to make nano-silver sol with a particle size of 80-100nm for later use.

[0050] 4. Add the coupling agent to ethanol, mix evenly, prepare a 1% ethanol solution of the coupling agent by volume, add 0.1% acetic acid by volume based on the ethanol solution of the coupling agent, the pH value is 3.5-5.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com