Method for enabling nano-micron porous luminescent fibers to be attached to surface of non-woven fabric treated with flash evaporation method

A technology of non-woven fabrics and luminous fibers, which is applied in the direction of non-woven fabrics, fiber treatment, fiber chemical characteristics, etc., can solve the problems that functionalization has not been widely studied and the degree of functionalization is low, and achieve enhanced mechanical properties and increased functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

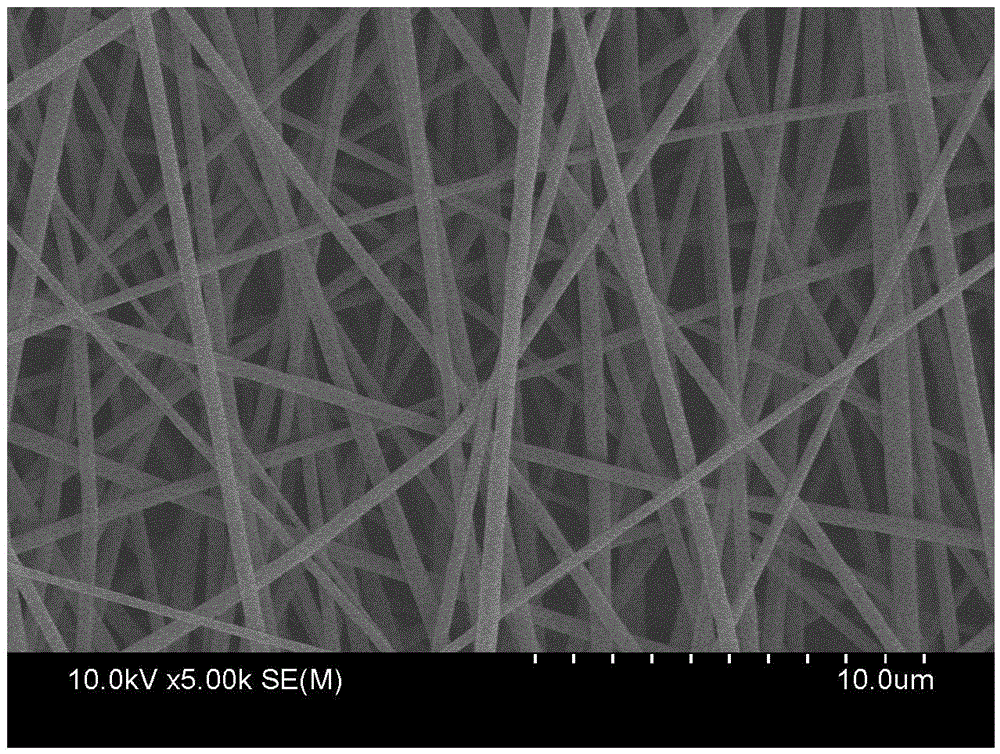

[0025] The preparation method of the present invention is to remove a part of the personal protective clothing, cut it into long strips with the same specifications, polish it with a fine steel brush and stick it on the receiving plate for receiving nano-micron porous luminescent fibers, and then electrospin The parameters of the device are fully adjusted, and the external conditions are adjusted to meet the conditions for obtaining nano-micron porous fibers. As the electrospinning proceeds, the surface of the flash nonwoven fabric is continuously adhered to the nano-micron porous luminescent fiber. When the nano-micron porous luminescent fiber is punched to a certain thickness, the flash nonwoven fabric can be removed to obtain the obtained product of the present invention. product of. It can be applied directly after gluing or roller pressing.

[0026] According to the fluorescence data test, when the spinning time reaches 5-6 hours, the fluorescence intensity has stabilize...

Embodiment example 1

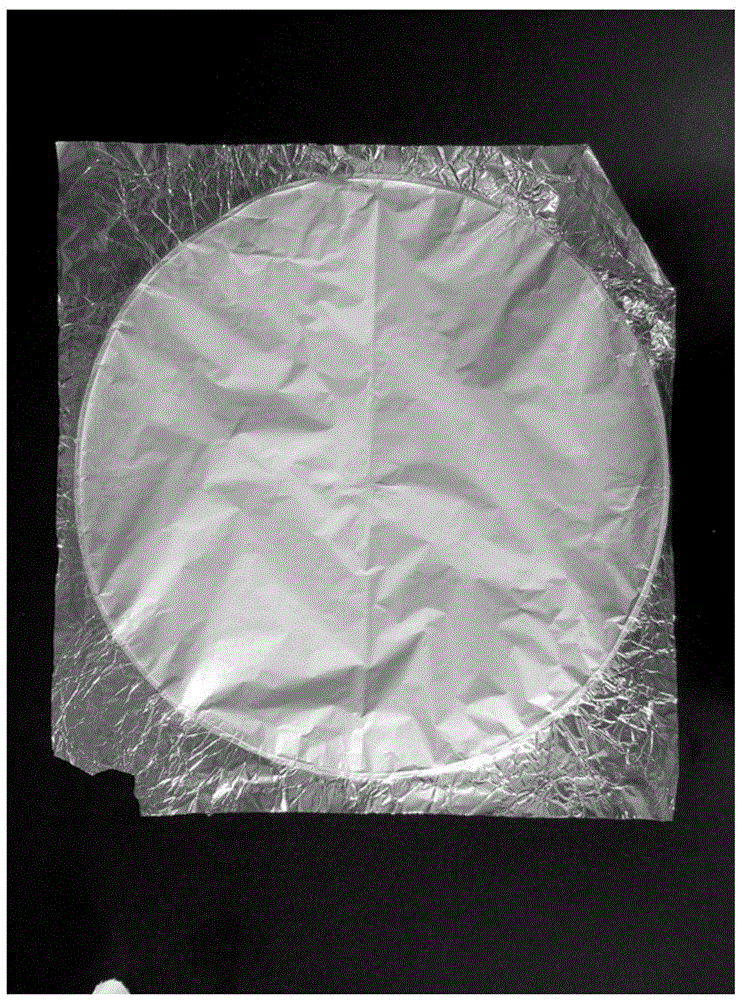

[0027] Implementation case 1: figure 1 In order to receive the flash non-woven fabric sample strip of electrospun nano-micro porous luminescent fiber, the specific method is to cut the flash non-woven fabric into a certain width and length of the spline, and then fix it on the receiving screen , for accepting electrospun fibers. As the electrospinning proceeds, a layer of nano-microporous luminescent fibers can be received on the flash nonwoven fabric.

Embodiment example 2

[0028] Implementation case 2: figure 2 For the nano-micro porous luminous fiber prepared by electrospinning, the specific method is to paste a layer of tin foil paper on the receiving screen, and the electrospun nano-micro porous luminescent fiber will adhere to the surface of the tin foil paper after solidification. The silver-white one in the figure is Tin foil paper, the white one is a film made of nano-micron porous luminescent fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com