High-frequency electromagnetic induction straight hot press heating plate

A high-frequency electromagnetic and heating plate technology, which is applied in the field of press equipment, can solve the problems of mechanical structure damage, deformation, and gravity sagging of hot-pressed steel plates, and achieve the effects of saving resources, reducing costs, and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

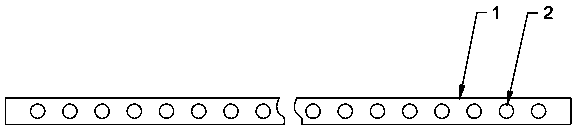

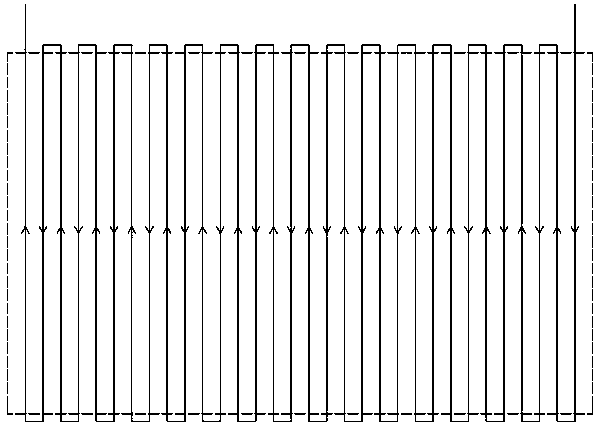

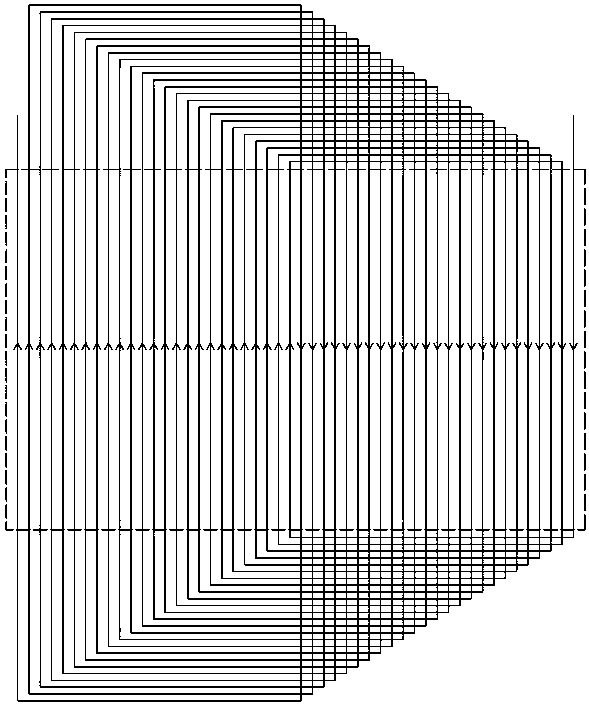

[0025] like figure 1 As shown, a heating plate of a high-frequency electromagnetic induction direct heating press according to the present invention includes a steel plate 1 and a high-temperature electromagnetic wire. The steel plate 2 is preferably a carbon steel plate made of Q235, and the thickness is preferably 36-50 mm. The middle part of the steel plate 1 is provided with a row of wire holes 2 that run through the steel plate parallel to the upper and lower sides. The direction of the wire holes 2 is perpendicular to the length direction of the steel plate. The wire holes 2 are evenly arranged at equal intervals. , the distance between the center of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com