Contact unit for connector

A technology of connectors and contacts, which is applied in the direction of contact parts, etc., can solve the problems of reducing the effect of elastic elements, permanent deformation of pressure springs, and reduction of contact piece pressing force, etc., and achieves small restoring force, small thermal conductivity, and good temperature compensation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

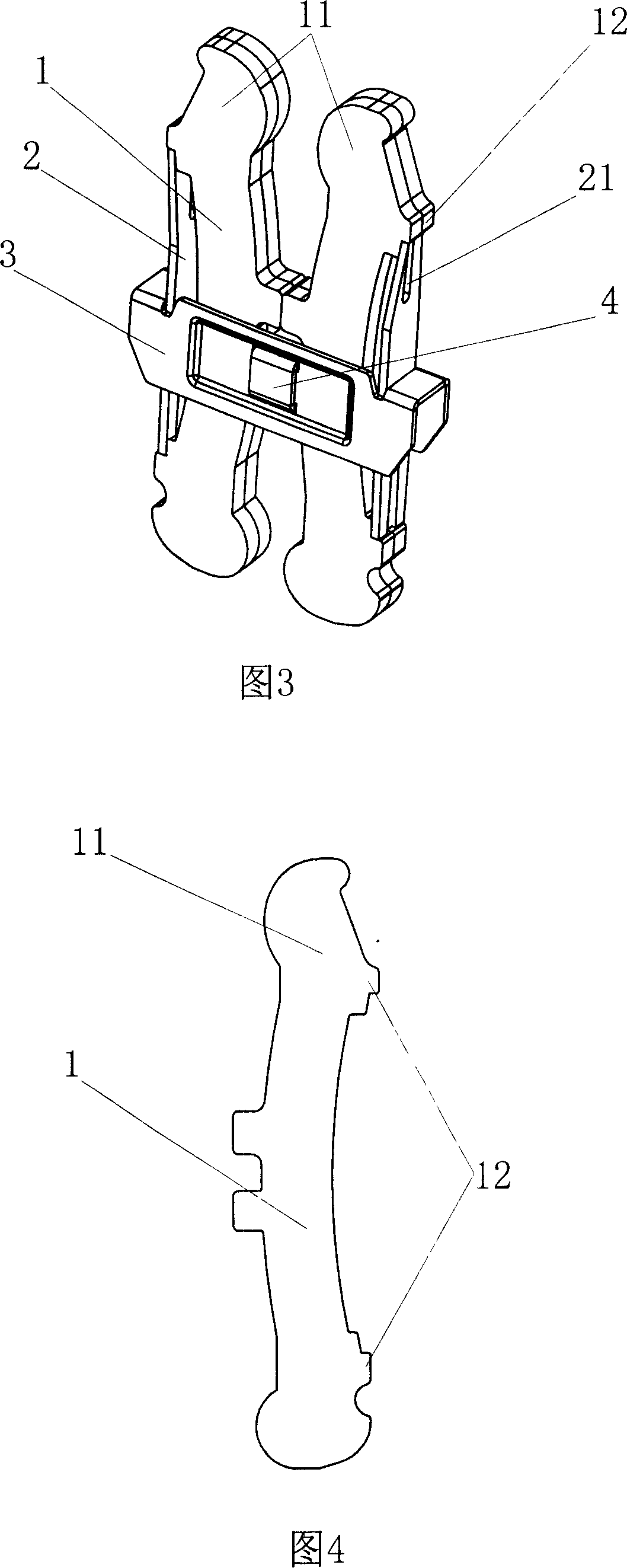

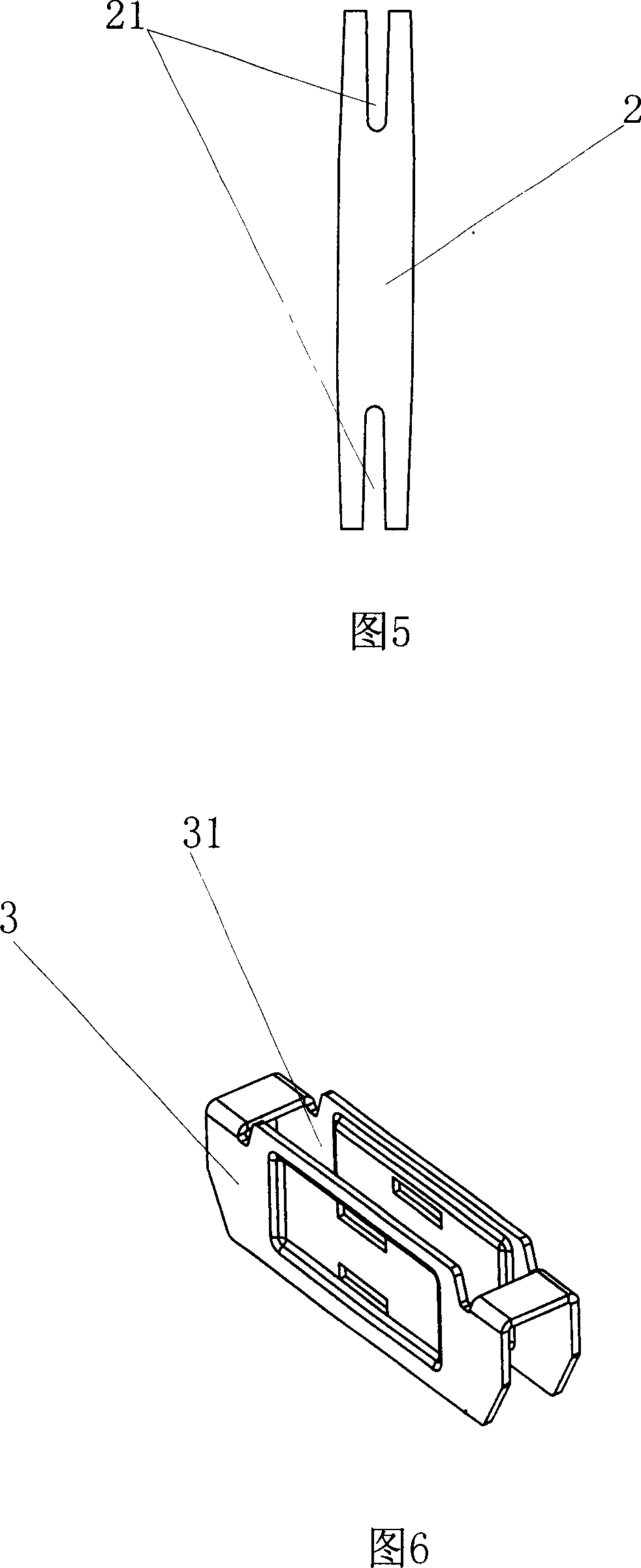

[0014] As shown in Figures 3, 4, 5, and 6, a specific embodiment of the present invention is a contact unit for a connector, the contact unit has two pairs of contact fingers 1, and contact claws at both ends of each contact finger 1 The outer side of 11 is symmetrically provided with bumps 12, and the outer ends of the contact fingers 1 are respectively provided with a linear spring 2, and the two ends of the linear spring 2 form a comb-shaped opening 21, and the two ends of each pressure spring 2 are pressed against the The pressure spring of the contact unit is formed on the two bumps 12 on the same side of the contact finger 1. A spring frame 3 is plugged in the middle of the contact unit. The spring frame 3 is provided with a contact finger 1 and a linear spring 2 along the longitudinal direction. Inserted socket 31, the inner wall of socket 31 and linear spring 2 form limit fit, the center of spring frame 3 is provided with latch opening, and U-shaped latch 4 passes latch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com