Microsample sampling system based on sinker EDM (Electric Discharge Machining) principle

A sampling system and electric spark technology, applied in sampling devices and other directions, can solve problems such as large damage to equipment, uncontrollable thickness, and inability to sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

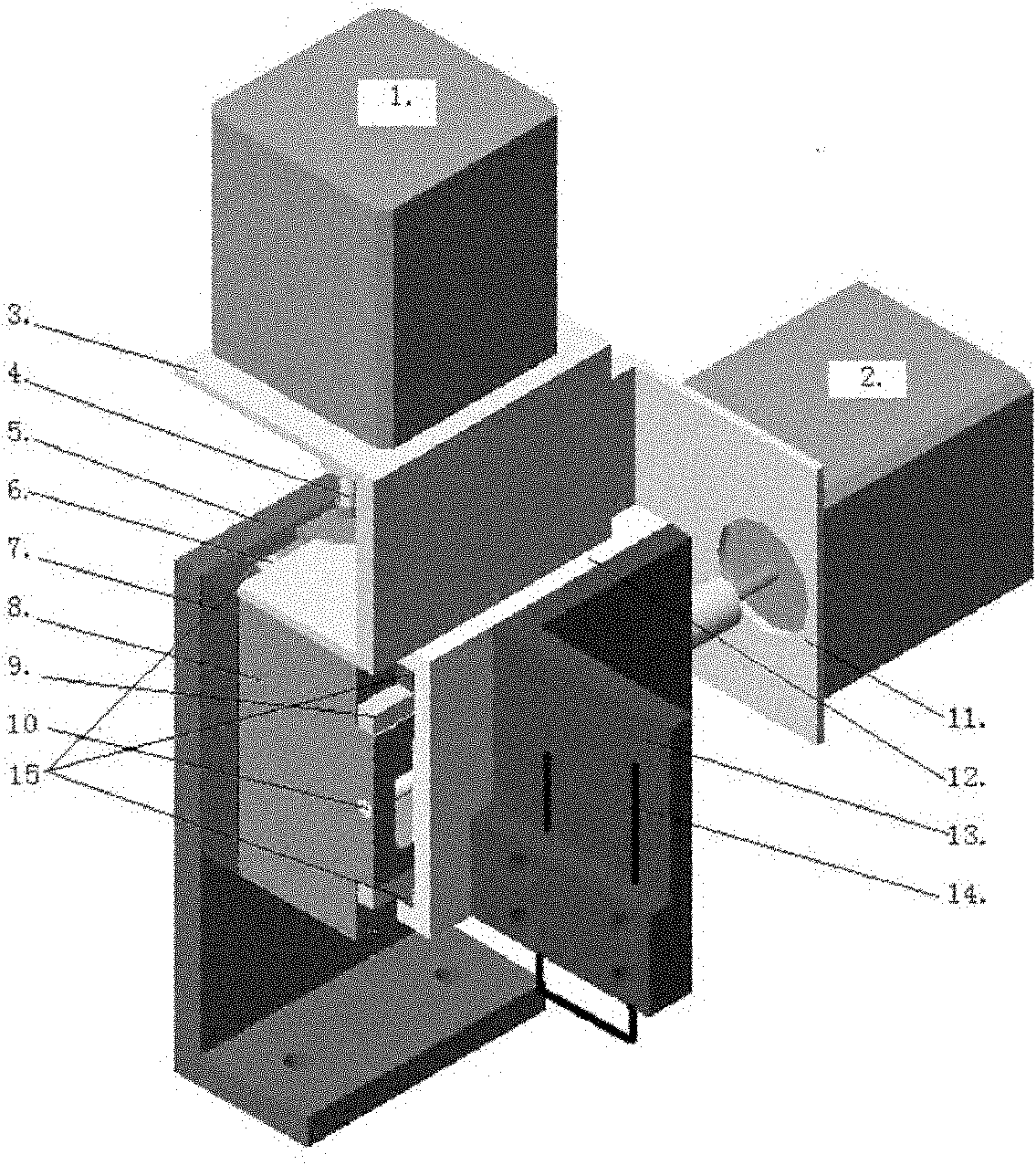

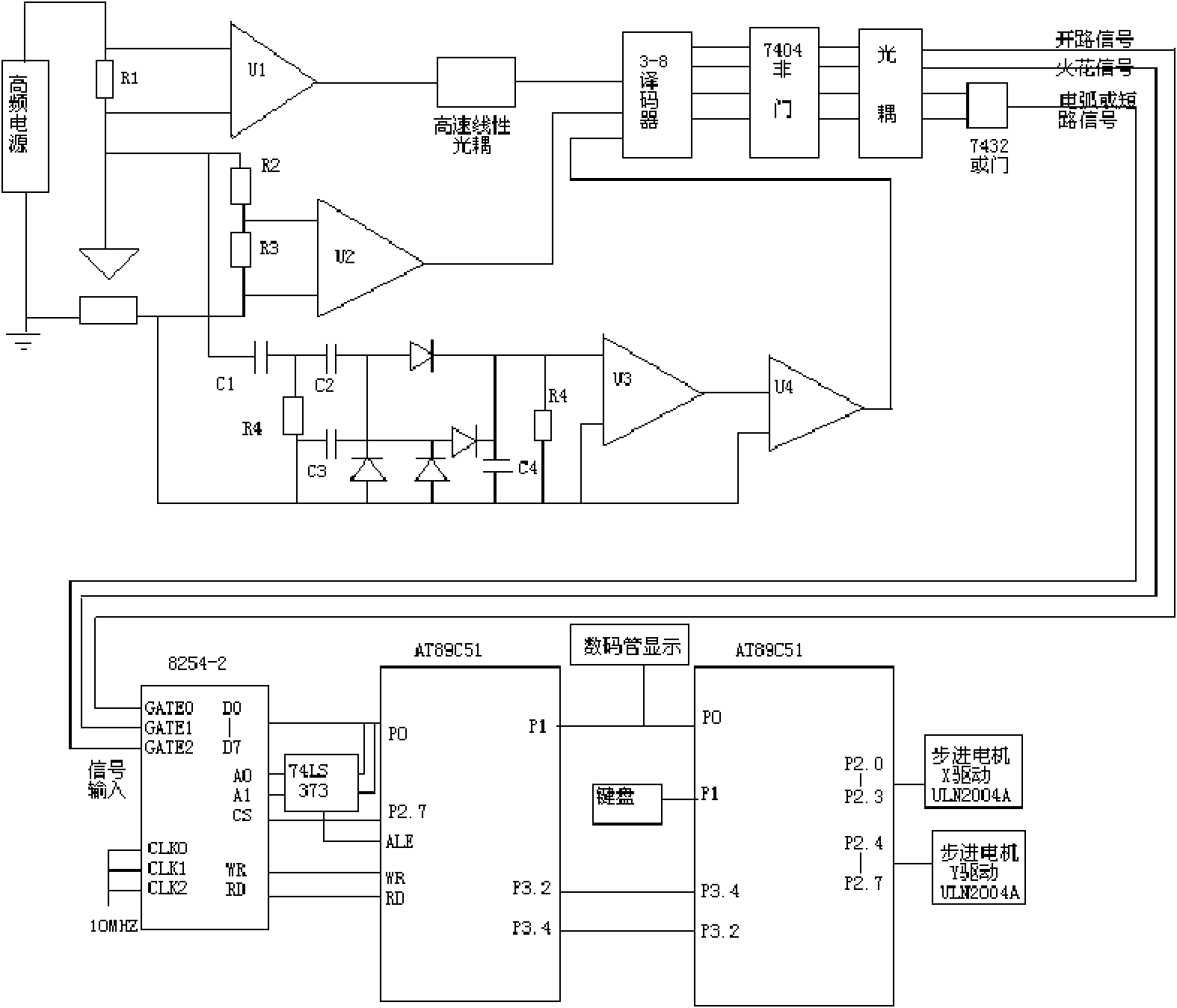

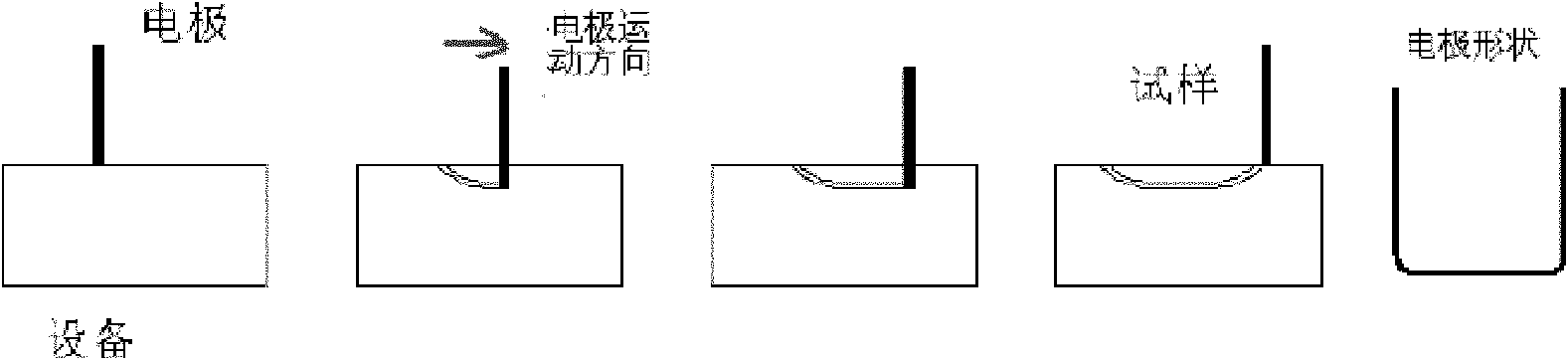

[0021] like figure 1 As shown, it is a schematic diagram of the mechanical stroke positioning mechanism of the micro-sample sampling system based on the principle of electric discharge forming according to the present invention. The sampling system includes an electric spark forming power supply, electrodes, a mechanical stroke mechanism, a signal detection unit and a single-chip control unit. The electric spark forming power supply provides pulse voltages for the electrodes; the mechanical stroke mechanism is mainly used to control the movement of the electrodes. The mechanical stroke mechanism includes: X-direction slide table, Z-direction slide table, slide table fixing mechanism, ball screw, linear guide rail, linear guide rail pair, stepper motor, coupling, electrode clamping mechanism, electrode, bracket and machine Base; the signal detection unit includes a current signal detection module, a voltage signal detection module and a high-frequency signal detection module; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com