Black ceramic and method for enhancing blackness of black ceramic

A technology of black ceramics and blackness, which is applied in the field of black ceramics and increasing the blackness of black ceramics. It can solve the problems of easy peeling off of antifouling film and achieve the effects of easy operation, cost reduction and pollution prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An embodiment of the method for increasing the blackness of black ceramics according to the present invention, this embodiment takes a sputtering machine as an example, and the preparation method is as follows:

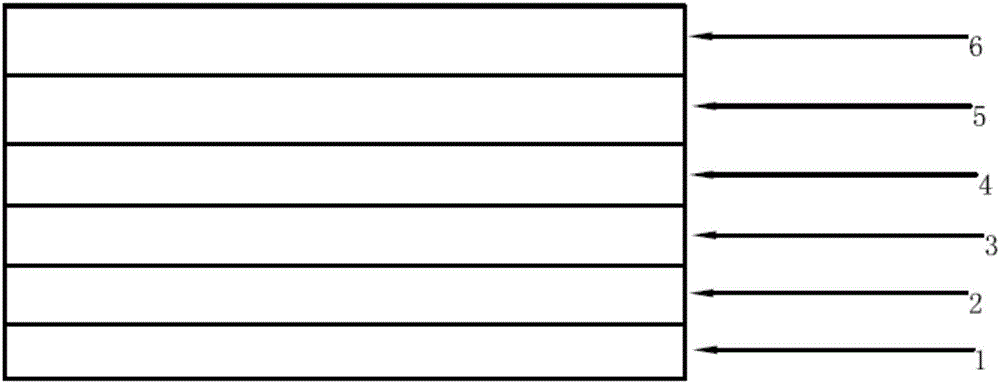

[0045] 1. Film system design, based on the design of TFCALC, requires a high transmittance of visible light in the 380-720nm band. It is recommended to use the film stack M2HL. In order to ensure that the AR film is colorless, it is obtained after a series of optimized designs The film structure is: Si 3 N 4 (15.15nm) / SiO 2 (41.29nm) / Si 3 N 4 (50.43nm) / SiO 2 (17.54nm);

[0046] 2. The sputtering machine sputters and coats, and sets the coating parameters:

[0047] 2.1 Initial vacuum degree: 6.0~7.0×10 -4 torr, coating temperature: 80-85°C, use RF treatment before coating, free radical source power: 3400-3600W, oxygen flow rate: 120sccm, time 300s;

[0048] 2.2 Silicon target sputtering power: 7600~8000W, argon flow: 110~120sccm, nitrogen flow: 90 sccm, ...

Embodiment 2

[0057] A kind of embodiment of the method for increasing the blackness of black ceramics described in the present invention, this embodiment takes vapor deposition machine as example, and preparation method is as follows:

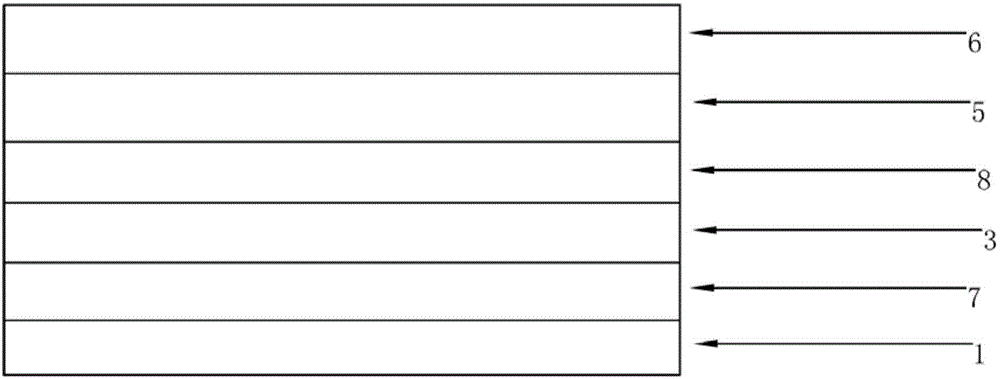

[0058] 1. Film system design, based on the design of TFCALC, requires a high transmittance of visible light in the 380-720nm band. It is recommended to use the film stack M2HL. In order to ensure that the AR film is colorless, it is obtained after a series of optimized designs The film structure is: Ti 3 o 5 (15.34nm) / SiO 2 (21.38nm) / Ti 3 o 5 (16.27nm) / SiO 2 (31.29nm);

[0059] 2. Evaporation machine coating process preparation:

[0060] Film system reference wavelength 550nm

[0061] The first layer: Ti 3 o 5 Film thickness 15.34nm; second layer: SiO 2 Film thickness 21.38nm; third layer: Ti 3 o 5 Film thickness 16.27nm; fourth layer: SiO 2 Film thickness 31.29nm; Coating vacuum degree: 2.2×10 -4 torr; substrate heating temperature: 20℃±5; co...

Embodiment 3

[0069] A kind of embodiment of the method for increasing the blackness of black ceramics described in the present invention, this embodiment takes vapor deposition machine as example, and preparation method is as follows:

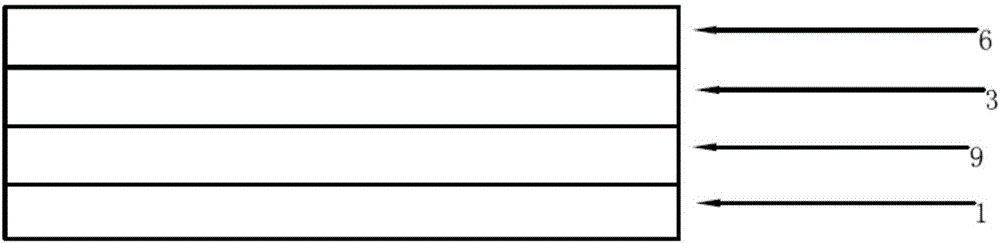

[0070] 1. Film system design, based on the design of TFCALC, requires a high transmittance of visible light in the 380-720nm band. It is recommended to use the film stack M2HL. In order to ensure that the AR film is colorless, it is obtained after a series of optimized designs The film structure is: ZrO 2 (20nm) / SiO2 2 (80nm);

[0071] 2. Evaporation machine coating process preparation:

[0072] Film system reference wavelength 550nm

[0073] The first layer: ZrO 2 Film thickness 15.15nm; second layer: SiO 2 Film thickness 41.29nm; Coating vacuum degree: 2.2×10 - 4 torr; substrate heating temperature: 20℃±5; coating substrate rotation frequency: 25n / min; electron gun high voltage: -8KV; evaporation rate: Ti 3 o 5 , 0.8 Å / s, SiO 2 , 1.5 Å / sec.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com