Carbon fiber and metal composite structure and preparation method thereof

A metal composite structure and carbon fiber technology, which is applied in the direction of metal layered products, chemical instruments and methods, and synthetic resin layered products, can solve the problem of affecting the reinforcement effect of aramid fiber reinforced carbon fiber and metal composite structures, and reduce the carbon fiber and metal composite structure. Structural bonding strength, adhesive viscosity and other problems, to achieve the effect of blocking galvanic corrosion, increasing surface roughness, and improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

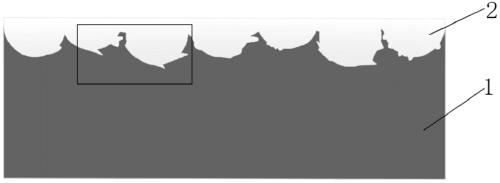

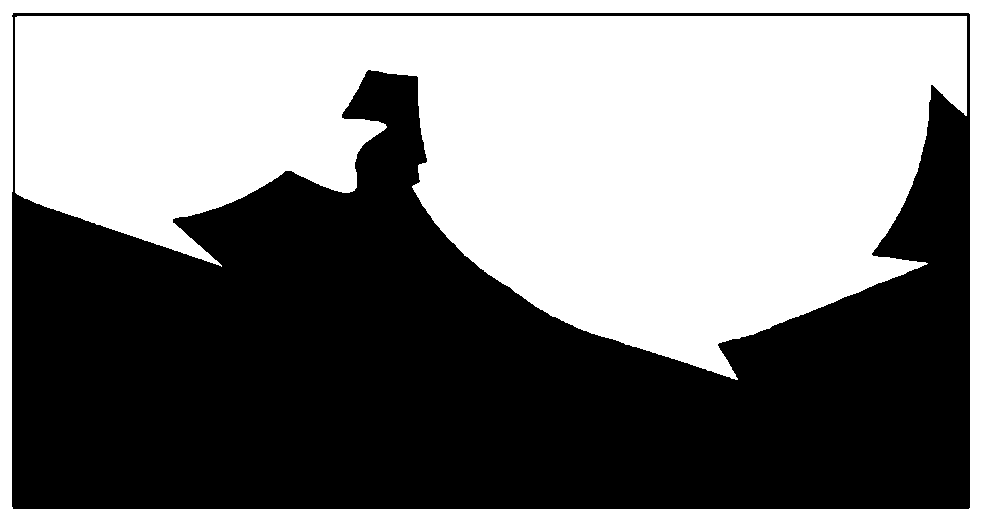

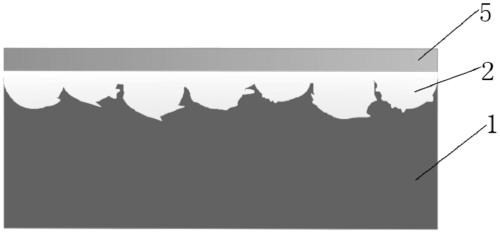

[0030] The present invention optimizes the carbon fiber and metal composite structure, and the specific metal can be steel or other alloy materials. In this embodiment, steel is taken as an example, and the steel surface is subjected to shot blasting or shot blasting treatment, causing the crystal lattice on the steel surface to be distorted and deformed. Form a plastic deformation layer on the steel surface, increase the hardness of the steel surface, and form a steel surface with a surface roughness several times the diameter of the aramid short fiber 4, increase the number of aramid short fiber 4 embedded in the rough steel surface, and strengthen the carbon fiber / steel The strength of the composite structure prolongs the service life of the composite structure. Due to the continuous impact of high-speed pellets on the steel surface, the crystal structure is distort...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com