Steel tube concrete and sprayed concrete stiff combined structure tunnel support system and construction method

A technology of shotcrete and steel pipe concrete, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as weak bonding ability, poor synergy, and distortion of steel arches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] This specific embodiment adopts the following technical solutions:

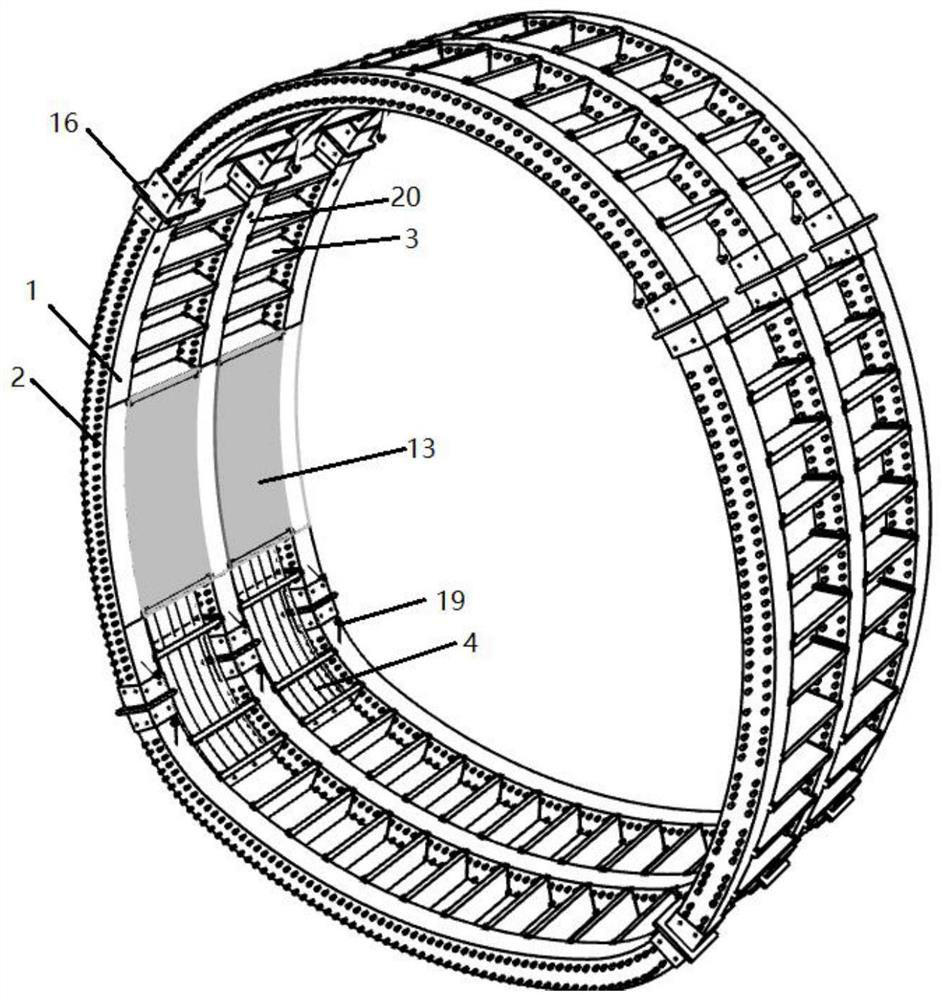

[0060] Such as figure 1 As shown, the concrete-filled steel tube and shotcrete combined rigid structure tunnel support system consists of concrete-filled steel tube arch frame 1, stud shear members 2, diaphragm 3, circumferential steel bars 4, and L-shaped panels 5. The concrete-filled steel pipe arch frame 1 is provided with multiple sections, which are arranged sequentially from the inside to the outside along the longitudinal direction of the tunnel. connection, such as Figure 15 , Figure 16 shown.

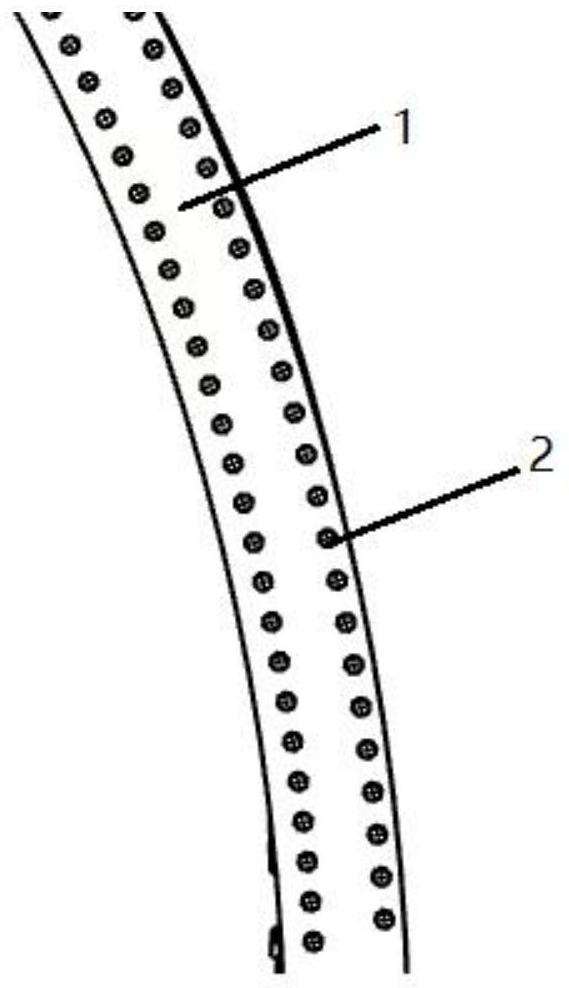

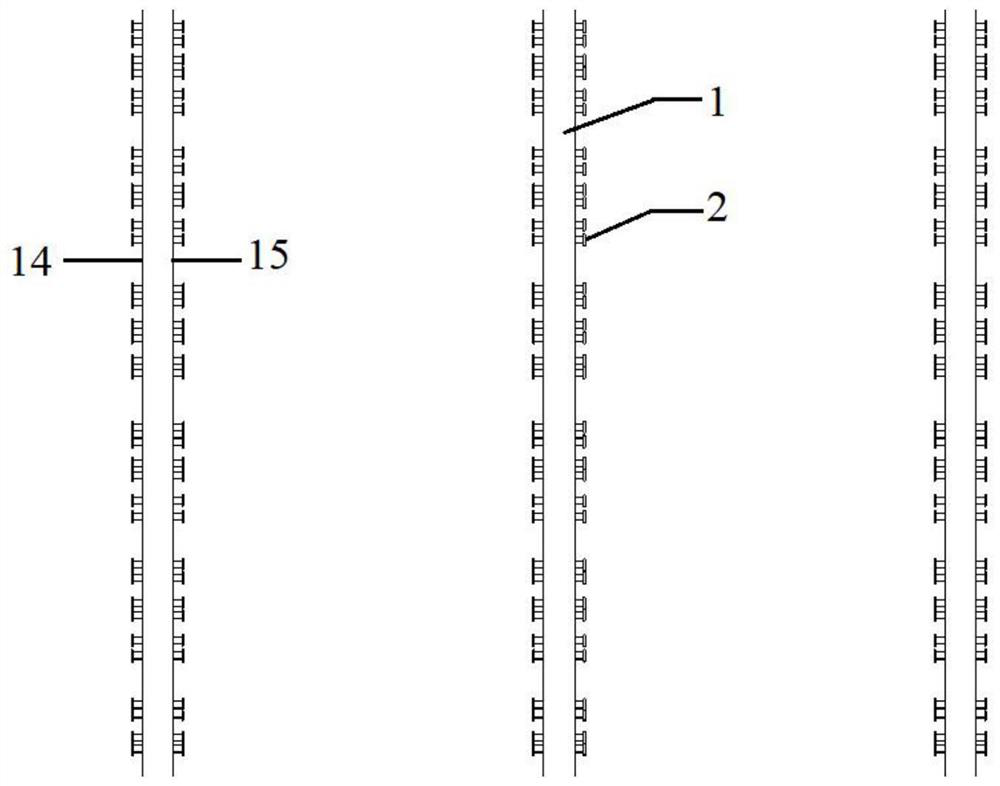

[0061] Such as figure 2 and image 3 As shown, the stud shear members 2 are welded to the square steel longitudinal outer pipe surface 14 and the square steel longitudinal inner pipe surface 15 of each concrete-filled steel tube arch frame 1 with a welding machine, and the stud shear members 2 are along the tunnel at a certain interval. Arranged in the circumferential direction, and the stud sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com