Method for improving crankshaft face plasma spraying Mo coating combination strength

A combination of strength and plasma technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of large unmelted particles in the coating, low particle speed, difficult to control the spraying process, etc., and achieve oil immersion friction The coefficient is small, the bonding strength is improved, and the effect of mechanical occlusion is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

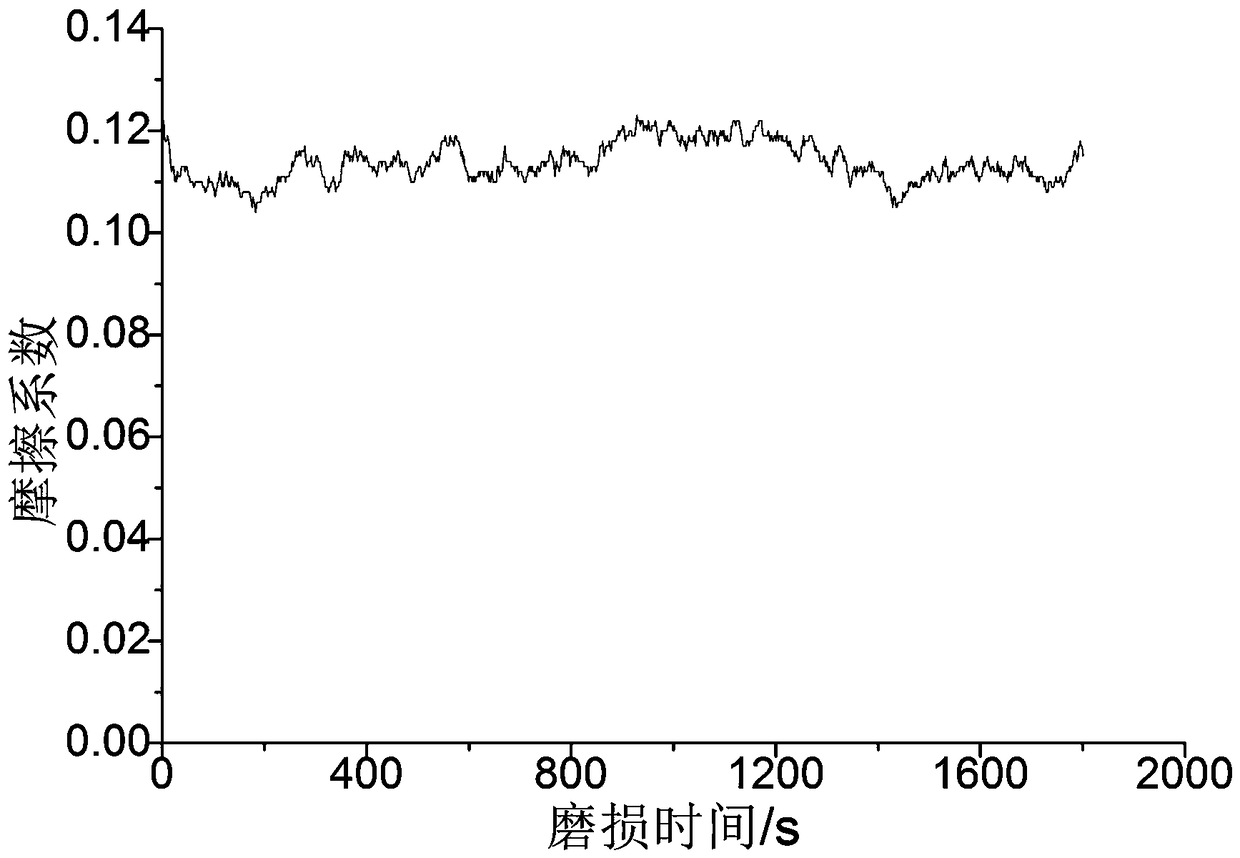

Embodiment 1

[0028]The diameter of the crankshaft in a plasma spraying embodiment described in this embodiment is 262 mm. After passing the blank inspection → milling end face centering → turning the short axis → rough grinding the spherical surface, after conventional degreasing and sandblasting, use plasma spraying equipment to spray Mo coating, adding 20% by weight of spherical WC-10Co-4Cr particles with a particle size of -30+5μm. Use straight nozzle, spraying distance 115mm, working current 620A, Ar gas velocity 40L / min, hydrogen velocity 9L / min, oxygen velocity 11L / min, powder feeding rate 40g / min, cooling gas pressure 0.45MPa, spraying gun body relative to crankshaft Spraying surface moving speed: 50mm / s, crankshaft surface temperature <150°C, Mo coating thickness 0.35mm. The oxygen content in the Mo-based coating was tested by an oxygen and nitrogen tester, and the oxygen content was 1.81. The hardness of the coating was measured by the HSRD-45 electric surface Rockwell hardness ...

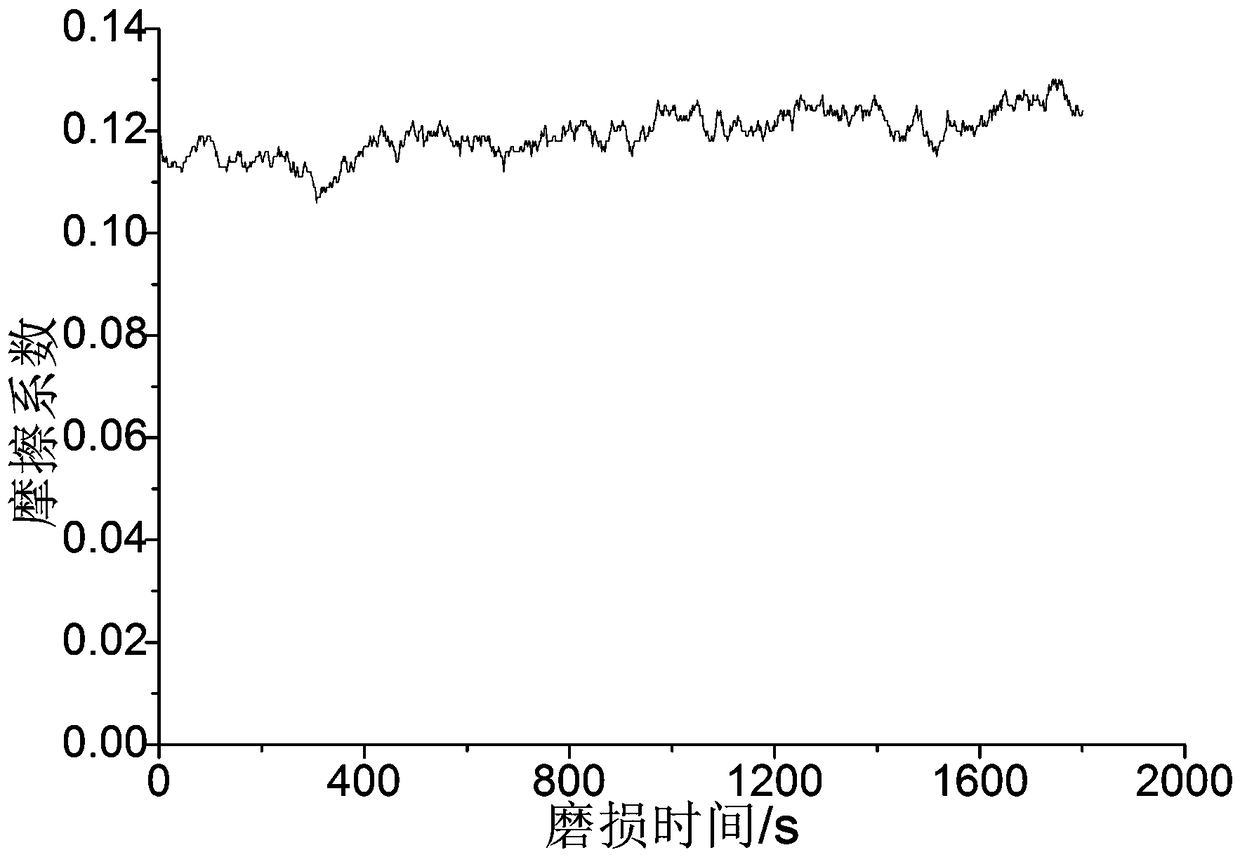

Embodiment 2

[0030] The diameter of the crankshaft in a plasma spraying embodiment described in this embodiment is 350 mm. After passing the blank inspection → milling end face centering → turning the short axis → rough grinding the spherical surface, after conventional degreasing and sandblasting, use plasma spraying equipment to spray Mo coating, adding 30% by weight of spherical WC-10Co-4Cr particles with a particle size of -30+5μm. Use straight nozzle, spraying distance 115mm, working current 620A, Ar gas velocity 40L / min, hydrogen velocity 9L / min, oxygen velocity 11L / min, powder feeding rate 40g / min, cooling gas pressure 0.45MPa, spraying gun body relative to crankshaft Spraying surface moving speed: 50mm / s, crankshaft surface temperature <150°C, Mo coating thickness 0.35mm. The oxygen content in the Mo-based coating was tested by an oxygen and nitrogen tester, and the oxygen content was 1.67. The hardness of the coating was measured by the HSRD-45 electric surface Rockwell hardness t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com