Solid-waste-based maritime work repair material and preparation method thereof

A technology for repairing materials and raw materials, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as weak bonding ability and poor erosion resistance, achieve improved strength, strong erosion resistance, and solve The effect of solid waste occupying arable land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

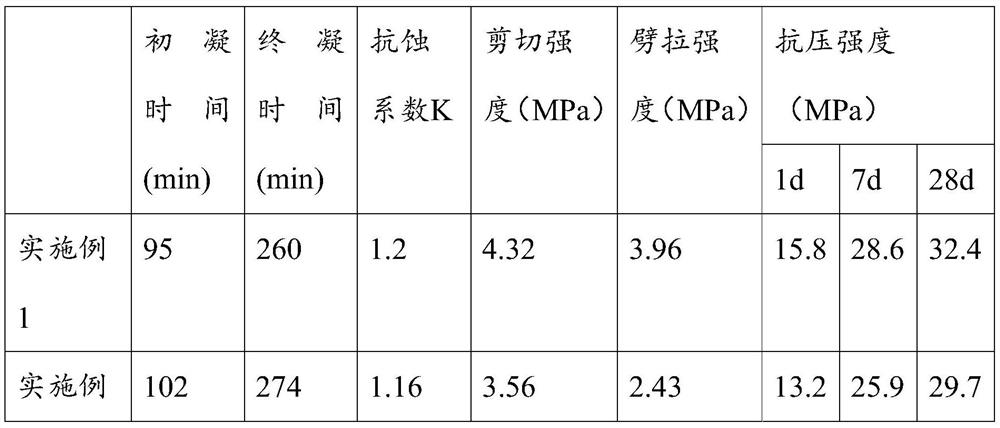

Embodiment 1

[0057] 1) Get 6.25g of cement, 5g of water glass, 6.25g of sodium hydroxide, 3.75g of calcium oxide, and 3.75g of sodium carbonate, and mix the three to prepare a composite alkaline stimulator;

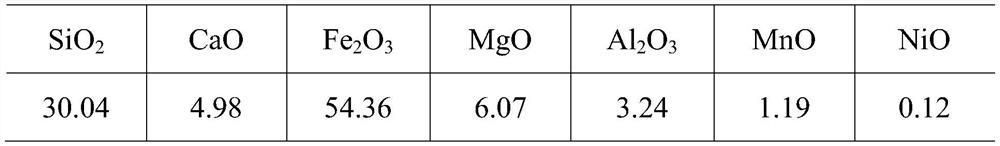

[0058] 2) Take 225g of activated red mud, 75g of activated nickel slag, 75g of sulphoaluminate cement, 5g of rubber powder, 50g of limestone powder, 5g of fiber, 30g of silica fume, and 10g of aliphatic amine curing agent;

[0059] 3) Add water to a water-cement ratio of 0.6, and stir well to prepare solid waste-based marine restoration materials.

Embodiment 2

[0061] 1) Get 6.25g of cement, 5g of water glass, 6.25g of sodium hydroxide, 3.75g of calcium oxide, and 3.75g of sodium carbonate, and mix the three to prepare a composite alkaline stimulator;

[0062] 2) Take 225g of unactivated red mud, 75g of activated nickel slag, 75g of sulfoaluminate cement, 5g of rubber powder, 50g of limestone powder, 5g of fiber, 30g of silica fume, and 10g of aliphatic amine curing agent;

[0063] 3) Add water to a water-cement ratio of 0.6, and stir well to prepare solid waste-based marine restoration materials.

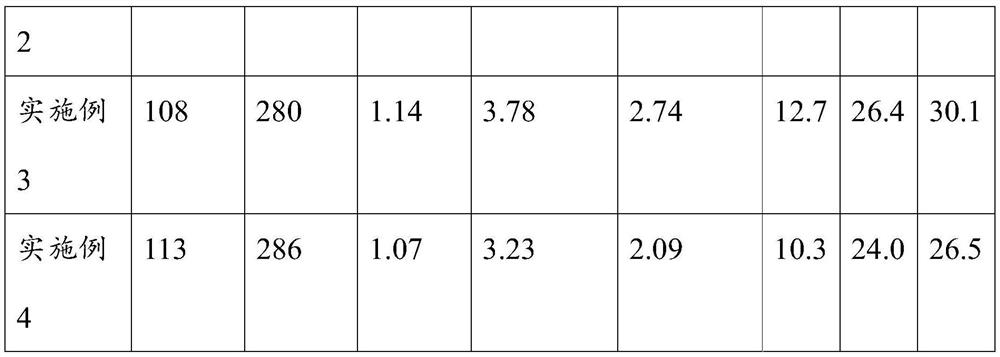

Embodiment 3

[0065] 1) Get 6.25g of cement, 5g of water glass, 6.25g of sodium hydroxide, 3.75g of calcium oxide, and 3.75g of sodium carbonate, and mix the three to prepare a composite alkaline stimulator;

[0066] 2) Take 225g of activated red mud, 75g of unactivated nickel slag, 75g of sulfoaluminate cement, 5g of rubber powder, 50g of limestone powder, 5g of fiber, 30g of silica fume, and 10g of aliphatic amine curing agent;

[0067] 3) Add water to a water-cement ratio of 0.6, and stir well to prepare solid waste-based marine restoration materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com