Nickel slag sand/nickel slag powder blended cement-based grouting material for construction, and preparation method of same

A technology of nickel slag powder for construction, applied in the field of cement-based grout mixed with nickel slag sand and nickel slag powder for construction and its preparation, to achieve the effects of good fluidity, high early strength and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

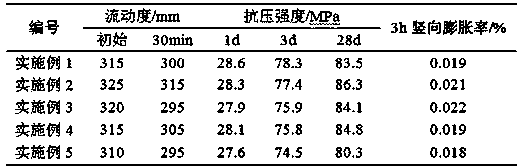

Examples

preparation example Construction

[0026] The invention provides a cement-based grouting material mixed with nickel slag sand and nickel slag powder for construction and a preparation method thereof. Based on the micro-expansion of nickel slag, a large amount of nickel slag sand and nickel slag obtained after crushing and ball milling are used. Nickel slag powder, respectively used as fine aggregate and part of the cementitious material in the system, realizes the reuse of solid waste resources and achieves the purpose of energy saving and emission reduction.

[0027] The cement-based grouting material mixed with nickel slag sand and nickel slag powder for construction of the present invention, the specific raw materials are as follows;

[0028] Nickel slag sand 52%-61%, nickel slag powder 6%-14%, cement 23%-35%, composite superfine powder 10%-17%, expansion regulator 1.5%-2.5%, polycarboxylate superplasticizer 1.3%-1.7%, reinforcing agent 0.5%-1.2%, defoamer 0.4%-0.9%, retarder 0.6%-1.2%, mixing water 11%-18%....

Embodiment 1

[0030] Cement-based grouting material embodiment 1 of the present invention;

[0031] The cement-based grouting material mixed with nickel slag sand and nickel slag powder for construction is prepared from the following raw materials according to the mass fraction: nickel slag sand 53%, nickel slag powder 9%, cement 26%, composite ultrafine powder 12%, expansion 1.8% conditioner, 1.4% polycarboxylate superplasticizer, 0.7% reinforcing agent, 0.5% defoamer, and 0.6% retarder. When mixing, add 16% of the water volume of the grouting material, and mix well. Can.

Embodiment 2

[0032] Cement-based grouting material embodiment 2 of the present invention;

[0033] The cement-based grouting material mixed with nickel slag sand and nickel slag powder for construction is prepared from the following raw materials according to the mass fraction: nickel slag sand 57%, nickel slag powder 9%, cement 24%, composite ultrafine powder 10%, expansion 1.5% conditioner, 1.6% polycarboxylate superplasticizer, 0.8% reinforcing agent, 0.7% defoamer, 0.7% retarder, when mixing, add water accounting for 14% of the mass of the grouting material, fully mix evenly Can.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com