Polymer stabilizer-fatty ammonium salt for increasing recovery ratio

A technology of fatty ammonium salt and polymer, which is applied in drilling compositions, preparation of organic compounds, organic chemistry, etc., can solve the problems of few research reports, low yield, immature synthesis technology, etc., and has broad application prospects. , The effect of inhibiting viscosity decay and superior product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

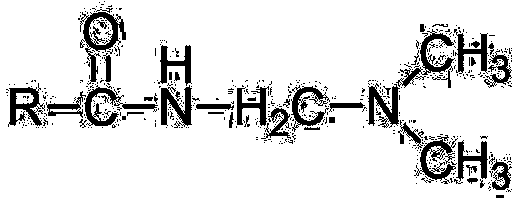

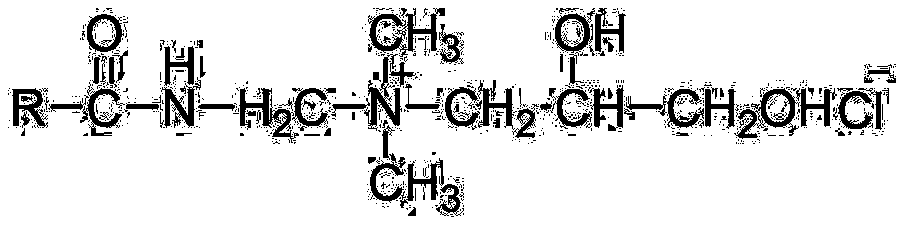

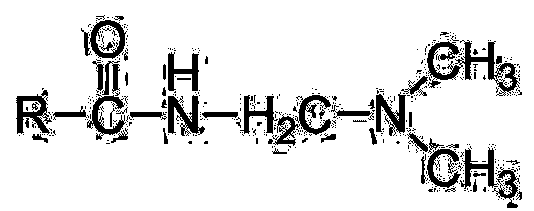

[0030] A polymer stabilizer-fatty ammonium salt for enhanced oil recovery,

[0031] The preparation of described fatty tertiary amine comprises the following steps:

[0032] (1) Octanoic acid and dimethyl-propylenediamine are put into the reaction kettle, the n (octanoic acid):n (dimethyl-propylenediamine)=1:1.5, then filled with nitrogen, and then the temperature rises to 140°C, closed reaction for 9.5 hours;

[0033] (2) The solution obtained in step (1) was distilled under reduced pressure for 30min, and excessive dimethyl-propylenediamine was steamed to obtain a crude product;

[0034] (3) Purify by repeated recrystallization, and obtain a light yellow solid product after vacuum drying. The conversion rate of fatty acid was 94.1%.

[0035] The preparation of described quaternary ammonium salt comprises the following steps:

[0036] (1) Put the tertiary amine product obtained by formula (I) and 3-chloro-1,2-propanediol into the reaction kettle, n(tertiary amine):n(3-chl...

Embodiment 2

[0039] A polymer stabilizer-fatty ammonium salt for enhanced oil recovery,

[0040] The preparation of described fatty tertiary amine comprises the following steps:

[0041] (1) Put myristic acid and dimethyl-propylenediamine into the reaction kettle, said n (myristic acid):n (dimethyl-propylenediamine)=1:2, and then fill with nitrogen, Then the temperature was raised to 150°C, and the reaction was closed for 9.5 hours;

[0042] (2) The solution obtained in step (1) was distilled under reduced pressure for 30min, and excessive dimethyl-propylenediamine was steamed to obtain a crude product;

[0043] (3) Purify by repeated recrystallization, and obtain a light yellow solid product after vacuum drying. The conversion rate of fatty acid was 94.2%.

[0044] The preparation of described quaternary ammonium salt comprises the following steps:

[0045] (1) Put the tertiary amine product obtained by formula (I) and 3-chloro-1,2-propanediol into the reaction kettle, n(tertiary amin...

Embodiment 3

[0048] A polymer stabilizer-fatty ammonium salt for enhanced oil recovery,

[0049] The preparation of described fatty tertiary amine comprises the following steps:

[0050] (1) Put capric acid and dimethyl-propylenediamine into the reaction kettle, the n (decanoic acid): n (dimethyl-propylenediamine) = 1: 1.5, then fill with nitrogen, and then the temperature Rising to 140°C, closed reaction for 9.5 hours;

[0051] (2) The solution obtained in step (1) was distilled under reduced pressure for 30min, and excessive dimethyl-propylenediamine was steamed to obtain a crude product;

[0052] (3) Purify by repeated recrystallization, and obtain a light yellow solid product after vacuum drying. The conversion rate of fatty acid was 94.5%.

[0053] The preparation of described quaternary ammonium salt comprises the following steps:

[0054] (1) Put the tertiary amine product obtained by formula (I) and 3-chloro-1,2-propanediol into the reaction kettle, n(tertiary amine):n(3-chloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com