A microbial repair agent for self-healing of marine concrete cracks

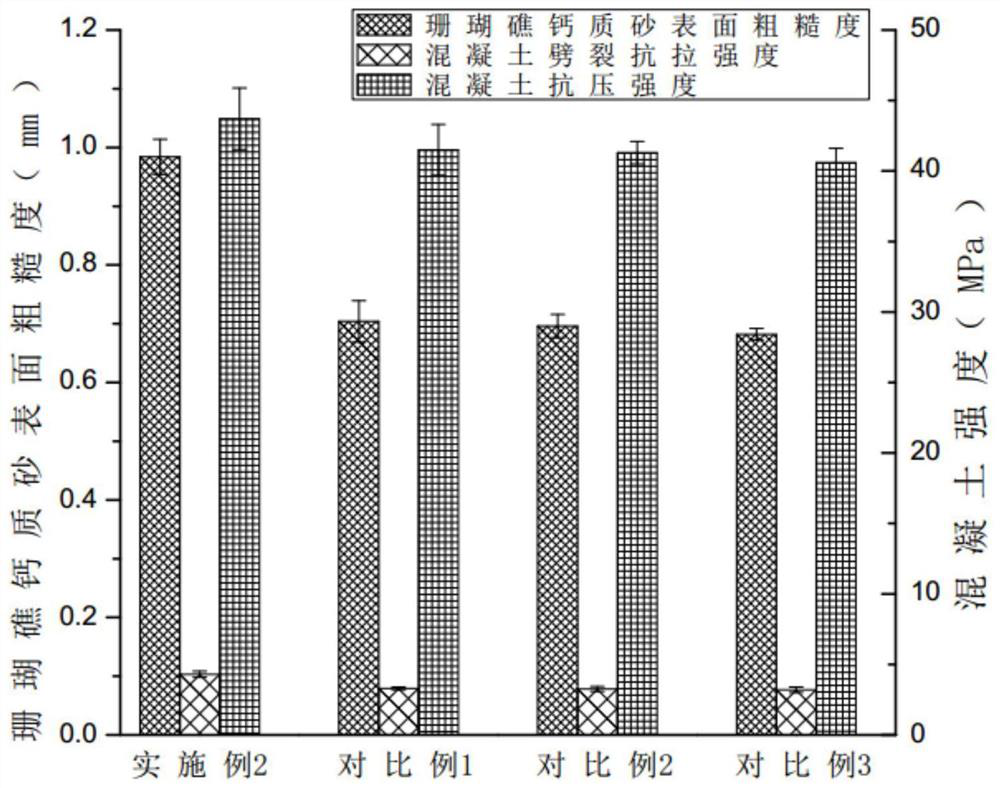

A microbial repair and concrete technology, applied in the field of concrete self-repair, can solve the problems of economic loss and casualties, damage accumulation, low tensile strength, etc., to reduce the generation of expansive erosion products, improve mechanical occlusal effect, improve the resistance The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method of a microbial remediation agent, comprising:

[0051] Treatment of coral reef calcareous sand: Weigh 50g of coral reef calcareous sand, put it into a 1000mL three-necked flask, prepare 1.8wt% polyoxyethylene anhydrous toluene solution, and add 55.6g polyoxyethylene anhydrous toluene solution to the above container In medium, stir mechanically, add a small amount of distilled water dropwise, absorb for 45min, add dropwise 100mL ethanol solution containing 2.4vol% vinyl methyl ether, absorb for 60min, filter with suction, wash with absolute ethanol and distilled water for 3 times, and dry at 42°C to constant weight.

[0052] Coral reef calcareous sand is crushed and sieved from coral reefs as raw materials to obtain solid particles with a particle size of less than 5mm, a fineness modulus of 2.5, and a bulk density of 1320kg / m 3

[0053] The liquid culture medium used by Bacillus coerlii is: peptone 5g, beef extract 3g, NaHCO 3 0.42g, Na 2 CO 3...

Embodiment 2

[0058] 200g bacteria-carrying coral reef calcareous sand is put into 400g the mixed solution that contains 12wt% calcium lactate and 3wt% Pingpingjia, and all the other parts are completely consistent with embodiment 1.

Embodiment 3

[0060] A preparation method for crack self-healing concrete, comprising:

[0061] The composition and parts by weight of the concrete include: 432 parts of cement, 225 parts of seawater, 430 parts of gravel, 20 parts of silica fume, 200 parts of the microbial remediation agent prepared by the present invention, 410 parts of river sand, and 4 parts of water reducing agent.

[0062] Among them, the cement used is Huaxin Cement Co., Ltd. P.O.42.5 cement; the maximum particle size of crushed stone is 20mm, and the bulk density is 1625kg / m 3 ;The water reducer is a high-efficiency polycarboxylate water reducer with a solid content of 40% and a water reducing rate of 26%. The river sand is ordinary quartz sand with a fineness modulus of 2.8 and a bulk density of 1560kg / m 3 ; Silica fume, average particle size 180nm, specific surface area 13000m 2 / kg; seawater is artificially prepared seawater, the chemical composition is: NaCl 24.53g / L, MgCl 2 5.2g / L, Na 2 SO 4 4.09g / L, CaCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com