Preparation method of dopamine modified glass fiber/unsaturated polyester composite material

A polyester composite material and glass fiber technology, which is applied in the field of dopamine-modified glass fiber/unsaturated polyester composite material preparation, can solve the problems of high cost, cumbersome treatment process, fiber damage interface bonding force, etc., and achieves comprehensive performance improvement. , The polymerization conditions are simple, and the effect of improving the interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

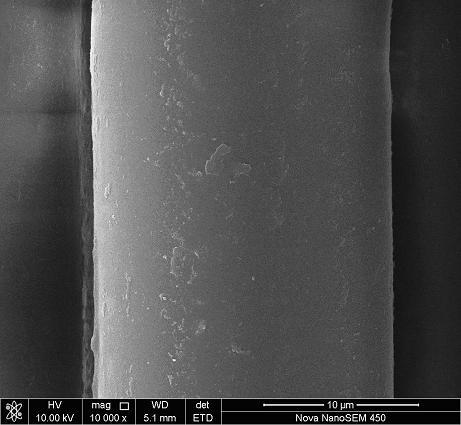

[0018] Take 10 pieces of 04 platinum glass fibers (20cm*30cm each), soak them in acetone for 4 hours, then wash them with deionized water and dry them with air at 60°C, then take them out for use. After weighing 191# unsaturated polyester resin, cyclohexanone peroxide and cobalt epoxy acid according to the ratio of 100:2:1, stir evenly, coat on a glass plate covered with release cloth, and spread a Layer glass fiber, and then brush a layer of resin solution, until all 10 pieces of glass fiber cloth are covered. After curing at room temperature for 4 hours, an unmodified glass fiber composite board was obtained.

Embodiment 2

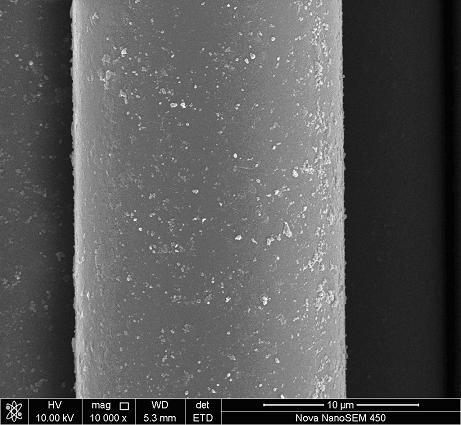

[0020] Take 10 pieces of 04 platinum glass fibers (20cm*30cm each), soak them in acetone for 4 hours, then clean them with deionized water and dry them with air at 60°C, then take them out for use. Prepare a 2.0 g / L dopamine hydrochloric acid solution, soak the desized glass fiber in the dopamine hydrochloric acid solution for 2 hours, take it out, wash it once with deionized water, and dry it in an oven at 60°C for later use. After weighing 191# unsaturated polyester resin, cyclohexanone peroxide and cobalt epoxy acid according to the ratio of 100:2:1, stir evenly, coat on a glass plate covered with release cloth, and spread a Layer glass fiber, and then brush a layer of resin solution, until all 10 pieces of glass fiber cloth are covered. Curing at room temperature for 4 hours to obtain a glass fiber composite board with a dopamine modification time of 2 hours.

Embodiment 3

[0022] Take 10 pieces of 04 platinum glass fibers (20cm*30cm each), soak them in acetone for 4 hours, then clean them with deionized water and dry them with air at 60°C, then take them out for use. Prepare a 2.0g / L dopamine hydrochloric acid solution, soak the desized glass fiber in the dopamine hydrochloric acid solution for 6 hours, take it out, wash it once with deionized water, and dry it in an oven at 60°C for later use. After weighing 191# unsaturated polyester resin, cyclohexanone peroxide and cobalt epoxy acid according to the ratio of 100:2:1, stir evenly, coat on a glass plate covered with release cloth, and spread a Layer glass fiber, and then brush a layer of resin solution, until all 10 pieces of glass fiber cloth are covered. Curing at room temperature for 4 hours to obtain a glass fiber composite board with a modification time of 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com