Sizing agent for graphene fibers and preparation method of sizing agent

A graphene fiber and graphene technology, which is applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of weak interfacial bonding, achieve the effect of increasing mechanical interlocking effect, easy batch preparation, and improved matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

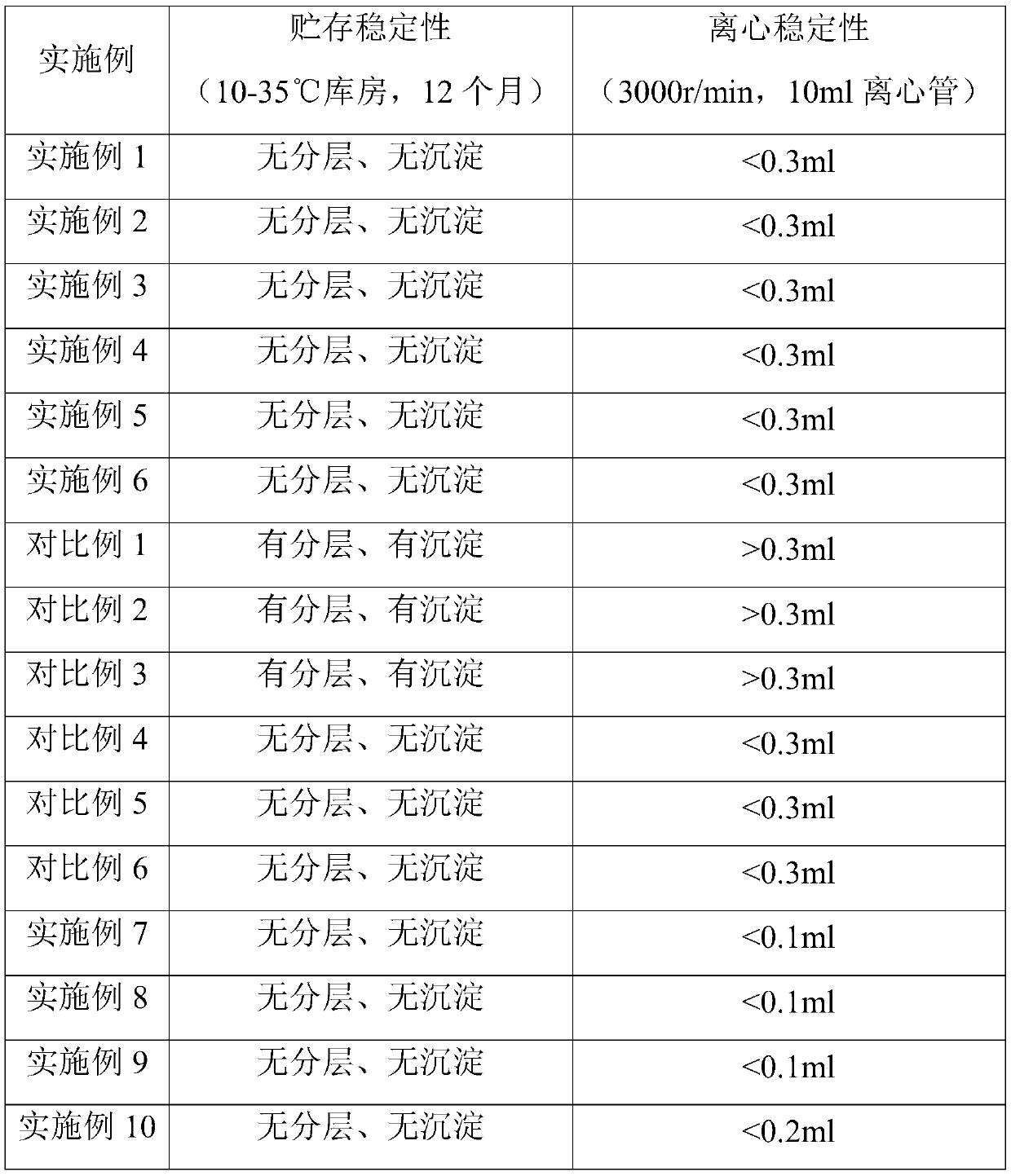

Examples

Embodiment 1

[0025] The preparation method of the sizing agent for graphene fibers of the present embodiment specifically comprises the following steps:

[0026] Step 1. Take 45 parts of liquid bisphenol A epoxy resin, add 45 parts of alkylphenol polyoxyethylene ether (hydroxyl value 40mgKOH / g), heat to 105°C and mix evenly, vacuumize to remove residual moisture, and then cool down to 80 , ℃ began to add 10 parts of chain extender diphenylmethane diisocyanate and then keep warm for 6 hours to obtain epoxy resin emulsifier;

[0027] Step 2. After mixing 50 parts of liquid bisphenol A epoxy resin and 10 parts of epoxy resin emulsifier, start to add 10 parts of deionized water, and when the phase transition of the mixed system begins, continue stirring and add deionized water at the same time 30 parts, obtain epoxy resin emulsion;

[0028] Step 3, adding the graphene aqueous solution into the epoxy resin emulsion, adding deionized water and stirring fully at the same time to prepare a sizing...

Embodiment 2

[0031] The preparation method of the sizing agent for graphene fibers of the present embodiment specifically comprises the following steps:

[0032] Step 1. Take 50 parts of liquid bisphenol A epoxy resin, add 40 parts of alkylphenol polyoxyethylene ether (hydroxyl value 50mgKOH / g), heat to 105°C and mix evenly, vacuumize to remove residual moisture, and then cool down to 80°C , ℃ began to add 10 parts of chain extender and then keep it warm for 6 hours to obtain epoxy resin emulsifier;

[0033] Step 2. After mixing 45 parts of liquid bisphenol A epoxy resin and 10 parts of epoxy resin emulsifier evenly, start adding 10 parts of deionized water. When the phase transition of the mixed system begins, continue stirring and add deionized water at the same time 30 parts, obtain epoxy resin emulsion;

[0034] Step 3, adding 1 mg / ml graphene aqueous solution into the epoxy resin emulsion, adding deionized water while fully stirring to prepare a sizing agent for graphene fibers. Whe...

Embodiment 3

[0036] The preparation method of the sizing agent for graphene fibers of the present embodiment specifically comprises the following steps:

[0037] Step 1. Take 55 parts of liquid bisphenol A epoxy resin, add 35 parts of alkylphenol polyoxyethylene ether (hydroxyl value: 60mgKOH / g), heat to 105°C and mix evenly, vacuumize to remove residual moisture, and then cool down to 80°C , ℃ began to add 10 parts of chain extender and then keep it warm for 6 hours to obtain epoxy resin emulsifier;

[0038] Step 2. After mixing 40 parts of liquid bisphenol A epoxy resin and 8 parts of epoxy resin emulsifier according to a certain ratio, start to add 15 parts of deionized water, and when the mixed system begins to undergo phase transition, continue stirring and add 35 parts in deionized water, obtain epoxy resin emulsion;

[0039] Step 3, adding the graphene aqueous solution into the epoxy resin emulsion, adding deionized water and stirring fully at the same time to obtain a sizing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com