Surface mount circuit board, method for manufacturing surface mount circuit board, and method for mounting surface mount electronic devices

A technology for surface mounting and electronic devices, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, etc., and can solve problems such as the difficulty of laser beams reaching welding positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

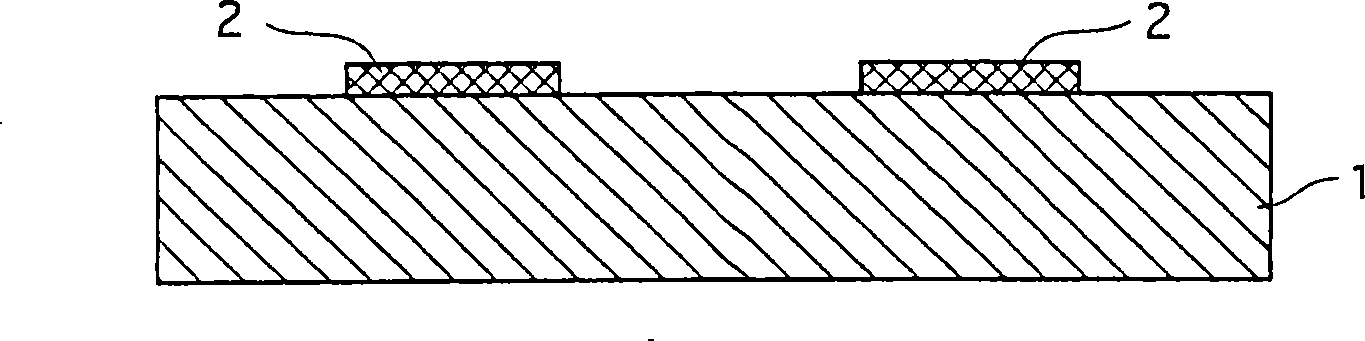

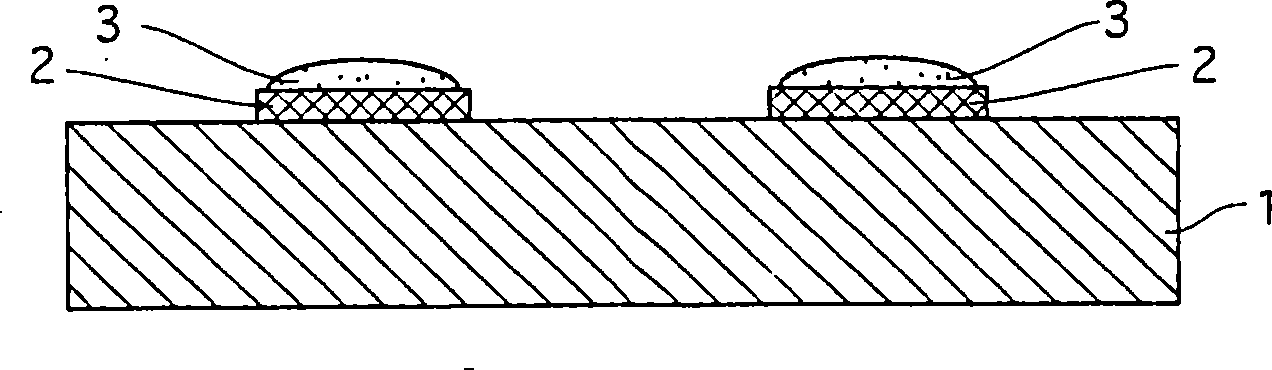

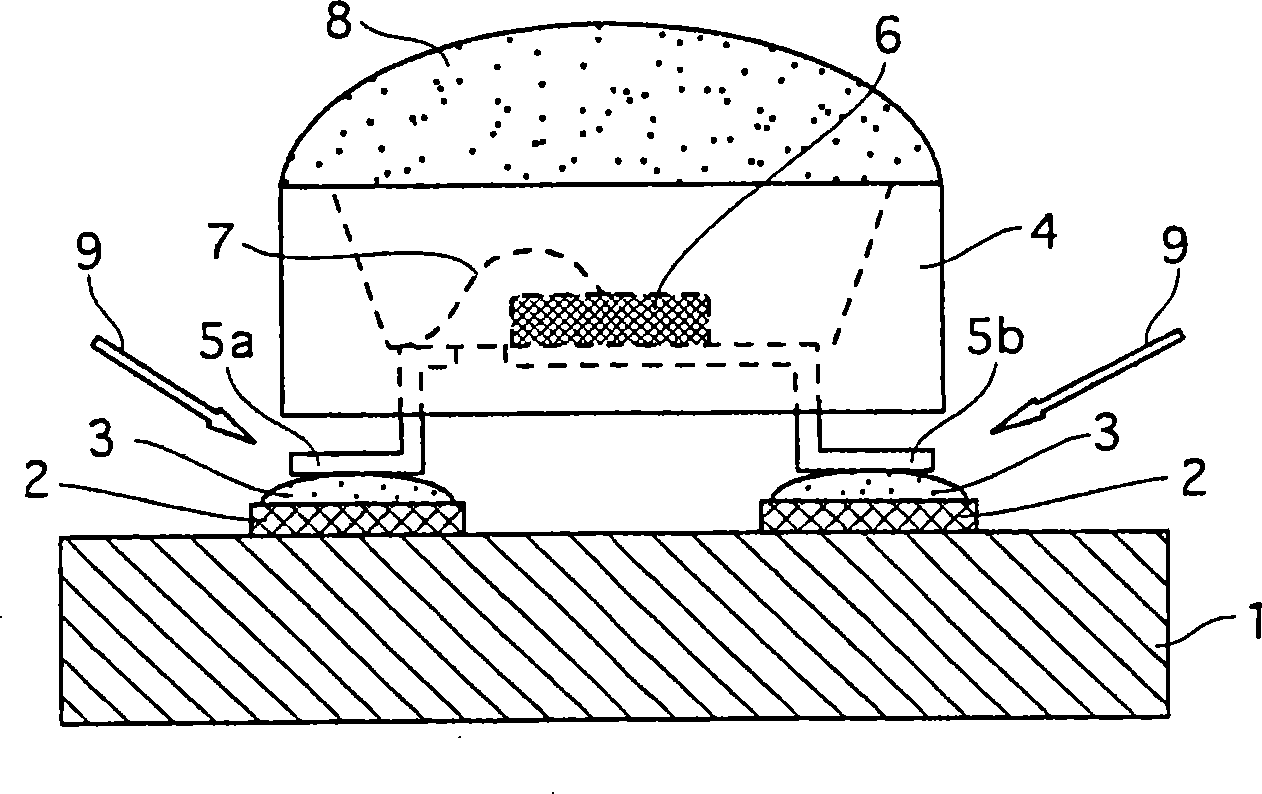

[0048] The embodiments of the present invention are described below in conjunction with the drawings.

[0049] Figure 5 It is a cross-sectional view of an important part of the surface mount circuit board according to the first embodiment of the present invention.

[0050] The surface mount circuit board according to the first embodiment includes an insulating substrate 1 having a plurality of through holes. Each through hole is located at a position where a pad is to be formed, and extends from the front surface to the back surface of the insulating substrate 1. In addition, each through hole is provided with a copper plating layer 11 covering the entire inner wall of the through hole and also covering part of the front and rear surfaces of the insulating substrate 1 around the peripheral edge of the through hole. Each through hole covered with the copper plating layer 11 (part 11a) is filled with a high thermal conductivity epoxy resin 12, which is obtained by mixing copper po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com