Method for soldering and welding hard alloy/steel compound tappet of engine by high-frequency induction

A high-frequency induction brazing and cemented carbide technology, which is used in welding/welding/cutting items, welding equipment, metal processing equipment, etc., and can solve the problems of low bending strength of joint parts, high production equipment requirements, and high production costs. , to achieve the effect of improving welding quality, reducing production costs and shortening the liquefaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

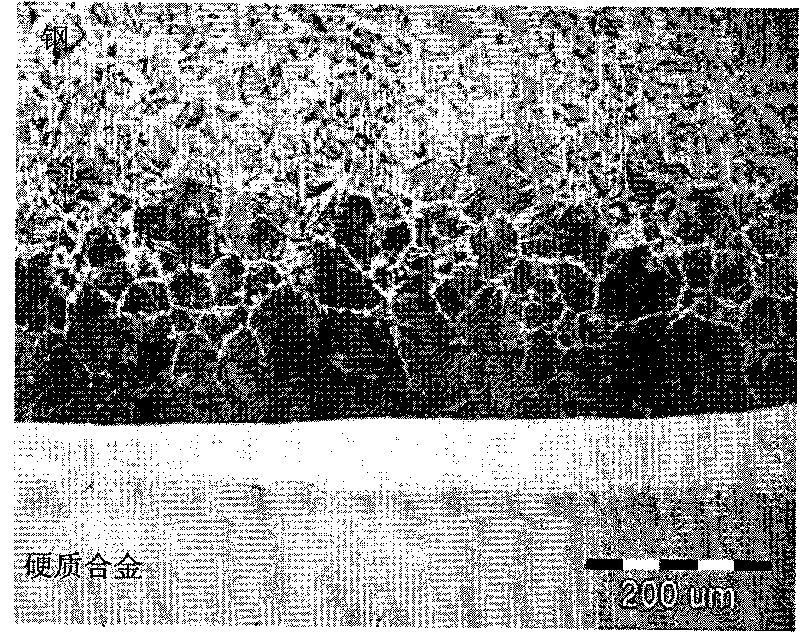

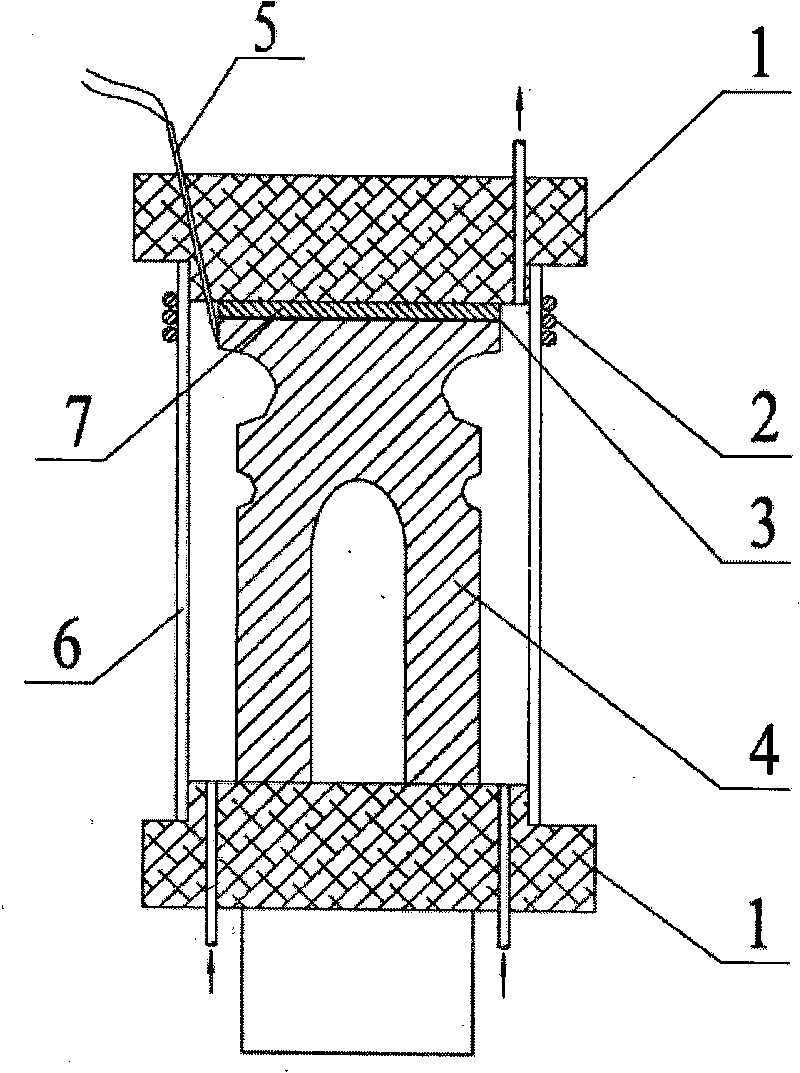

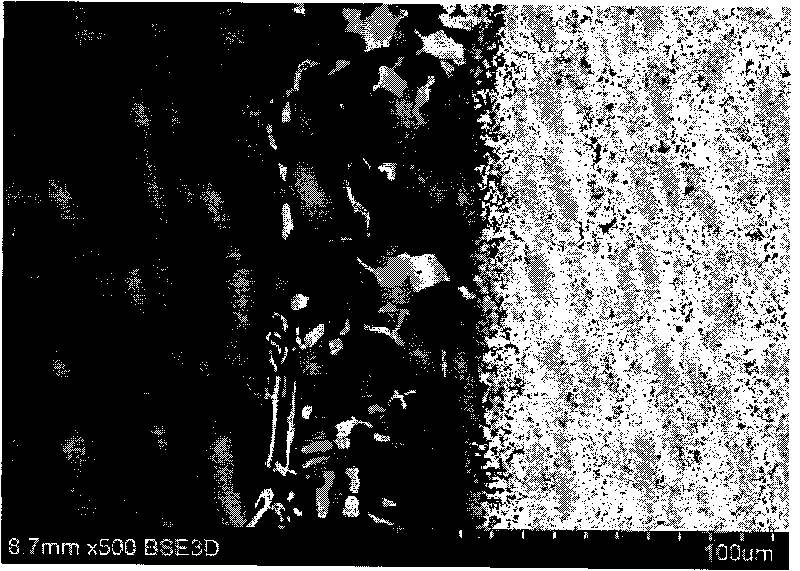

[0009] Specific embodiment one: the method for middle and high frequency induction brazing welding engine cemented carbide / steel composite tappet of this embodiment is to be finished by the following steps: : after the mass ratio of 1 is mixed, solder paste is obtained; Step 2, removes the oxide film on steel and hard alloy connection surface, then wipes with acetone (removes the greasy dirt on steel and hard alloy strip welding surface); Step 3, puts The solder paste prepared by step 1 is scraped and coated between the cemented carbide after step 2 processing and the connecting surface of steel to obtain the workpiece to be welded composed of cemented carbide-brazing paste-steel; step 4, the step 3. Put the parts to be welded into the quartz glass vacuum tube, seal the two ends with graphite columns and fix the parts to be welded, and then use high-frequency induction heating equipment to heat the parts to be welded under argon atmosphere for brazing: first use 7 The heating ...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Ni-Cr-Si-B brazing filler metal described in step one is made of 7.0% Cr, 4.5% Si, 3.1% B, 3.0% Fe by weight percentage , 0.01% to 0.1% C and the rest of Ni. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the binder described in step one consists of 0.8% to 1.2% glycerol and 1.6% to 2.4% hydroxyethyl Cellulose, 0.8%-1.2% carboxymethyl cellulose and 95.6%-96.4% distilled water. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Number of turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com