Multifunctional water-based ink spraying device

A water-based ink, spraying device technology, applied in printing devices, printing, typewriters and other directions, can solve the problems of limited spraying surface, poor spraying effect, small spraying application range, etc., to achieve good spraying effect, good spraying effect, avoid emptying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

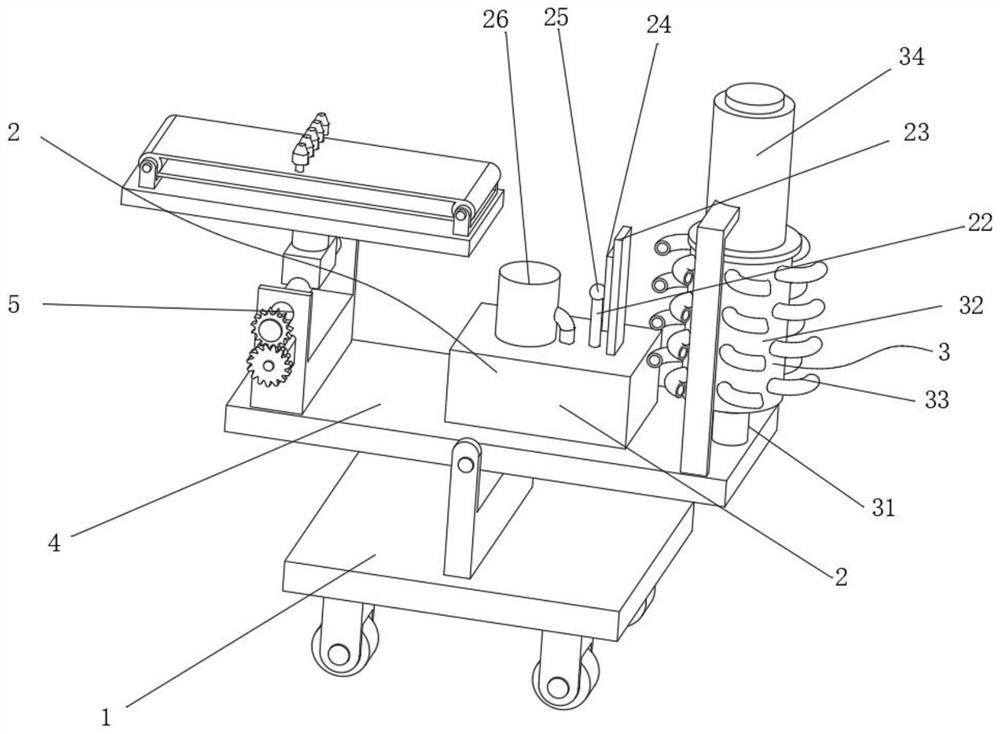

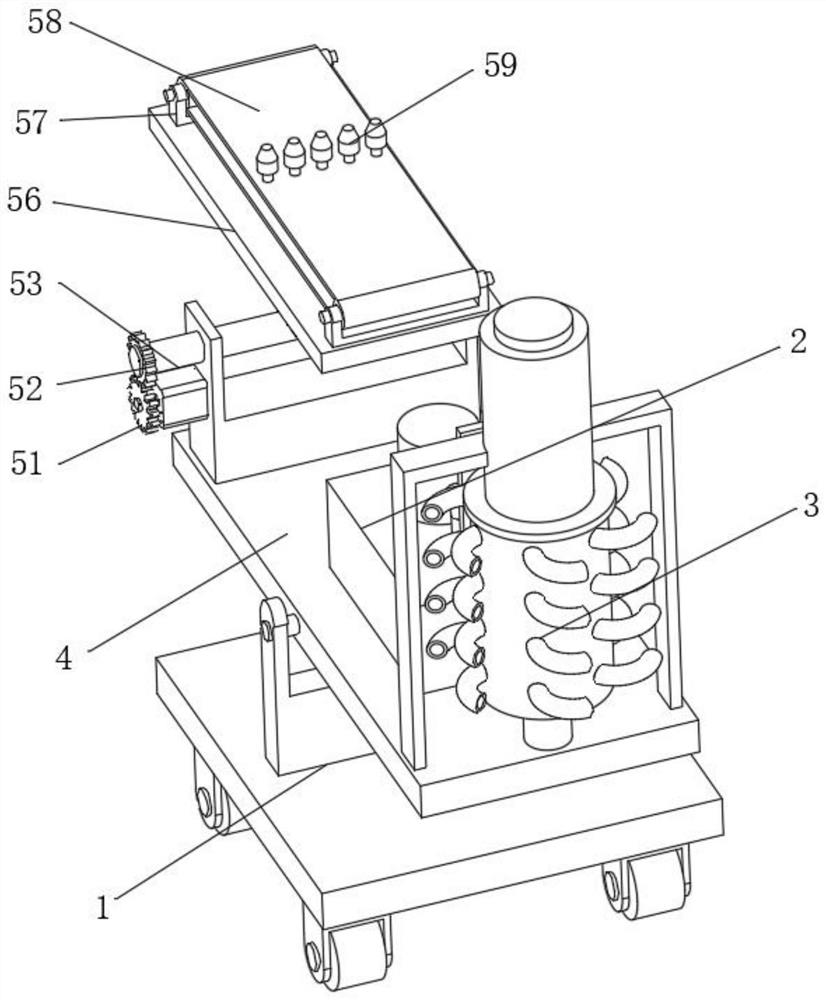

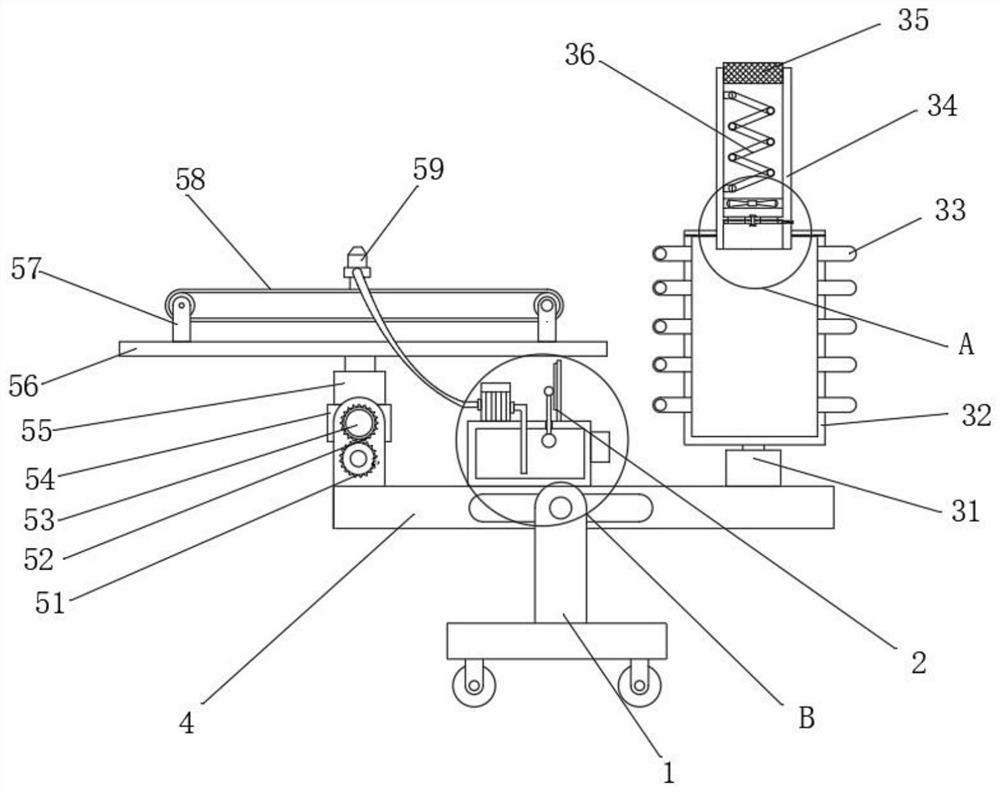

[0028] As an embodiment of the present invention, the displacement spraying structure 5 includes a driving gear 51, a matching gear 52, a driven shaft 53, a mounting frame 54, a servo motor 55, a displacement frame 56, a transmission frame 57, a transmission belt 58 and a spray head 59 The top side of one end of the swing frame 4 is arranged on the mounting seat, a power motor is installed on the mounting seat, a driving gear 51 is mounted on the rotating shaft of the power motor, and a driving gear 51 is mounted on the rotating shaft of the power motor. Driven shaft 53, a mounting frame 54 is welded on the peripheral surface of the middle part of the driven shaft 53, a servo motor 55 is mounted on the mounting frame 54, and a displacement frame 56 is mounted on the rotating shaft of the servo motor 55 , a drive frame 57 is installed on the displacement frame 56, a transmission belt 58 is installed on the transmission frame 57, a plurality of shower heads 59 are installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com