Injection molding method for thin-wall plastic part

A technology of injection molding and plastic parts, which is applied in the field of injection molding, and can solve the problems of warping of finished products, affecting the uniformity of melt injection, and small circulation channels, so as to reduce warping of finished products, prolong coagulation time, and reduce energy waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

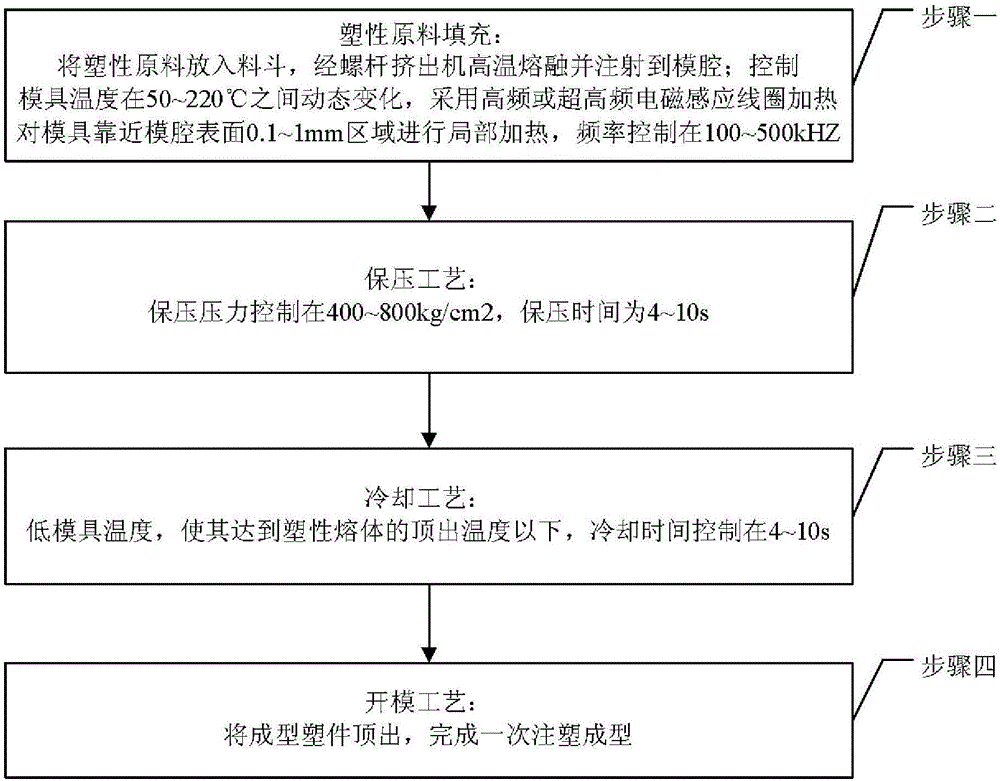

[0051] In a first exemplary embodiment of the present invention, an injection molding method of a thin-walled plastic part is provided. Such as figure 1 As shown, the injection molding method of the thin-walled plastic parts in this embodiment includes the following steps:

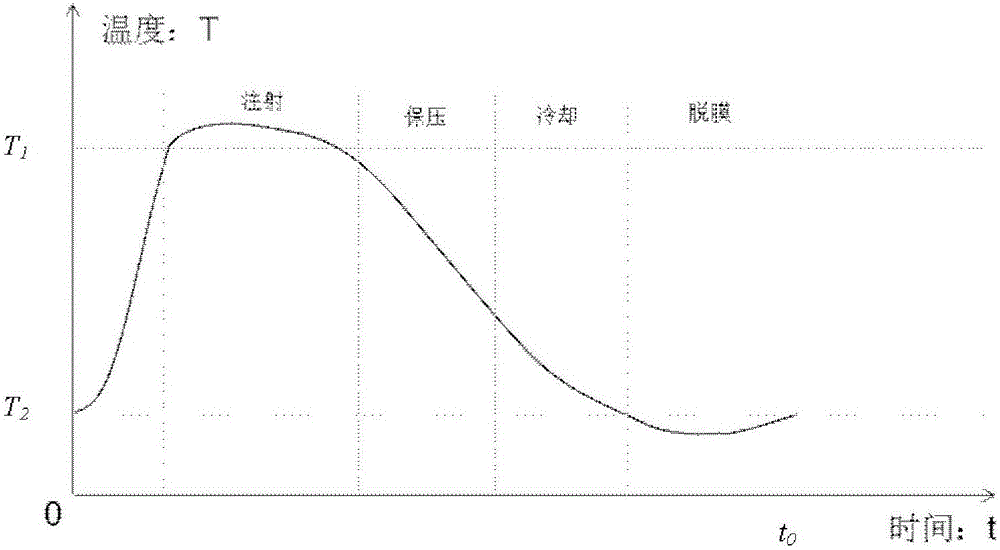

[0052] Step 1: Filling with plastic raw materials, put the plastic raw materials into the hopper, melt them at high temperature through the screw extruder and inject them into the mold cavity; the injection pressure is 1000-1200kg / cm 2 , the injection time is 1-4s, and the injection speed is controlled at 300-600mm / s; the mold temperature is controlled to change dynamically between 50-220°C, and the surface of the mold 1 close to the cavity 11 is hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com