Device and technology for plating surface of glass capillary tube with carbon film

A technology of capillary glass tube and carbon coating, which is applied in metal material coating process, gaseous chemical plating, coating and other directions to reduce energy loss and achieve the effect of local heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

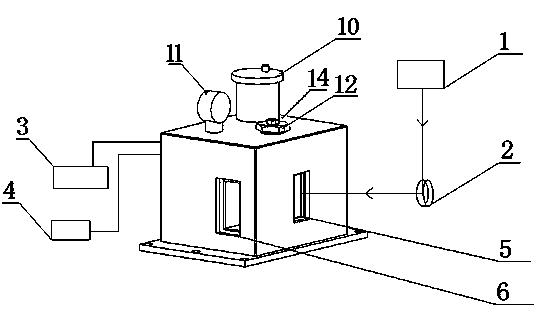

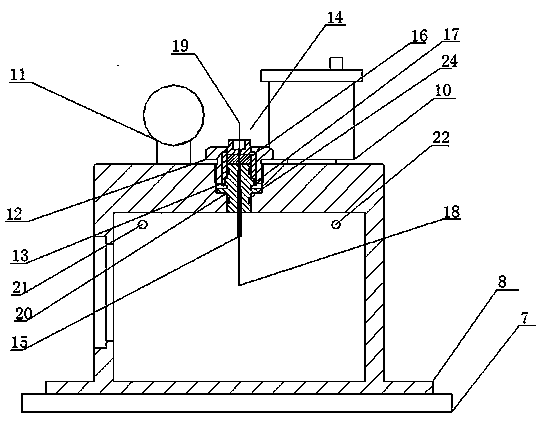

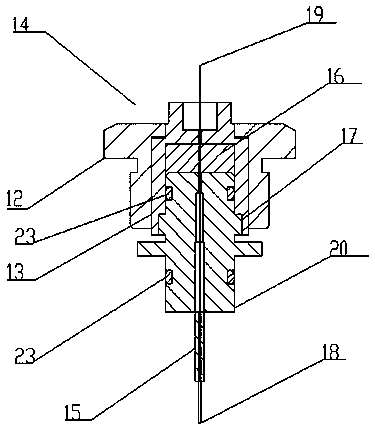

[0031] Such as Figure 1-2 As shown, a carbon coating device on the surface of a capillary glass tube includes a carbon dioxide laser marking machine 1 fixed on a base and a prism 2 cooperating with the carbon dioxide laser marking machine 1, and also includes a hollow shell 8. One side of the housing 8 is provided with a light-transmitting window corresponding to the prism 2, and the other side of the housing 8 is provided with a first air hole 21 and a second air hole 22. The first air hole 21 communicates with the vacuum pump 3, and the second air hole 22 communicates with the vacuum pump 3. The acetylene nitrogen gas tank 4 is in communication; the housing 8 is provided with an optical fiber clamp 14 , and the inside of the housing 8 is hermetically sealed from the outside of the housing 8 .

[0032] The heating temperature of the capillary glass tube 18 can be adjusted by setting the marking length, laser intensity and time of the carbon dioxide laser marking machine 1; ...

Embodiment 2

[0039] The similarities between this embodiment and Embodiment 1 will not be repeated, the difference is that it is a process for coating the surface of a capillary glass tube with a carbon film, and it uses the device for coating a carbon film on the surface of a capillary glass tube described in Embodiment 1. , which includes the following steps:

[0040] (1) Build the carbon coating device on the surface of the capillary glass tube, fix the housing 8 on the position moving platform 7, put the rubber gasket 16 between the middle sleeve 13 and the collimating glass tube fixing seat 20, and carbon coating will be required The capillary glass tube 18 of the film is placed in the collimating glass tube 15 at the bottom of the optical fiber holder 14, the pigtail 19 passes through the rubber gasket 16, tightens the fastening nut 12, compresses the middle sleeve 13 and the rubber gasket 16, and puts the middle sleeve 13 The relative position to the housing 8 is marked, and the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com