Heat characterization method and structure for monitoring temperature of transistor in real time

A real-time monitoring and transistor technology, applied in thermometers, measuring heat, and thermometers using directly heat-sensitive electrical/magnetic components, etc., can solve problems such as inapplicability, affecting normal operation of circuits, and inability to measure device temperature in real time. Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

[0022] The transistor thermal characterization method of the present invention is firstly used to test the temperature of the device, which may be the self-heating temperature of the transistor, or the temperature at which other devices or heat sources in the circuit are coupled to the device under test. The invention can be used for reliability analysis or device, circuit optimization and other purposes.

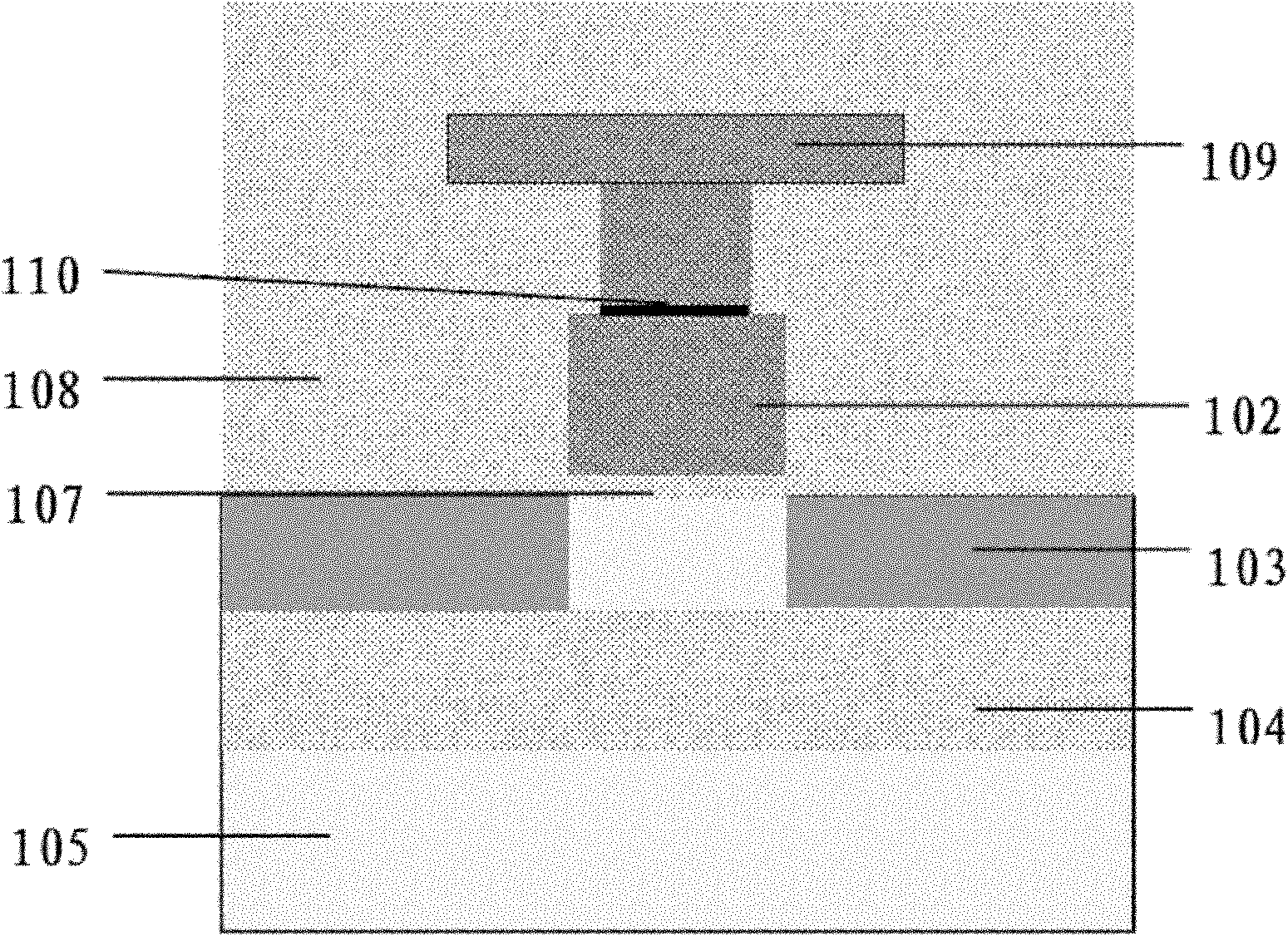

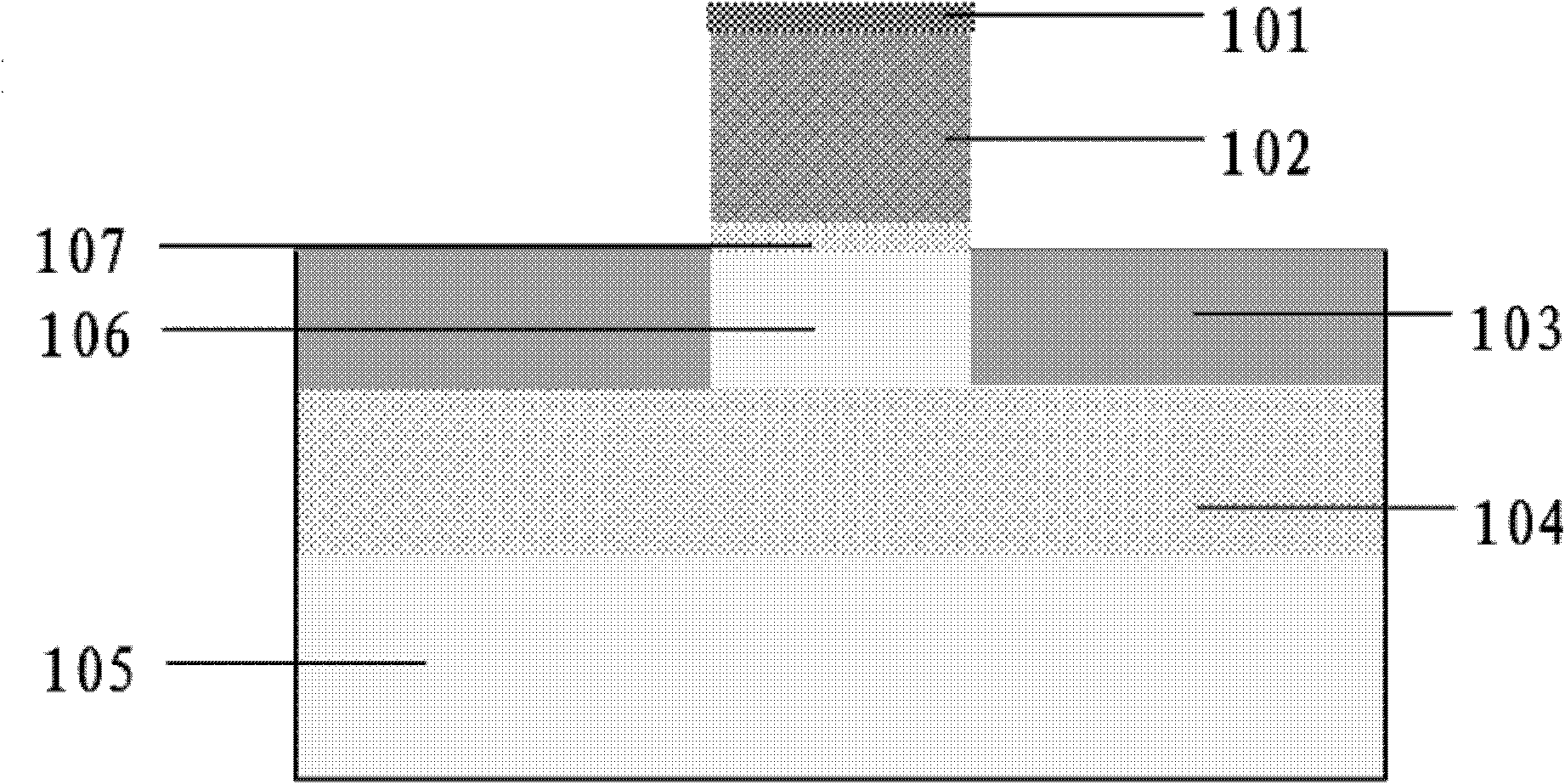

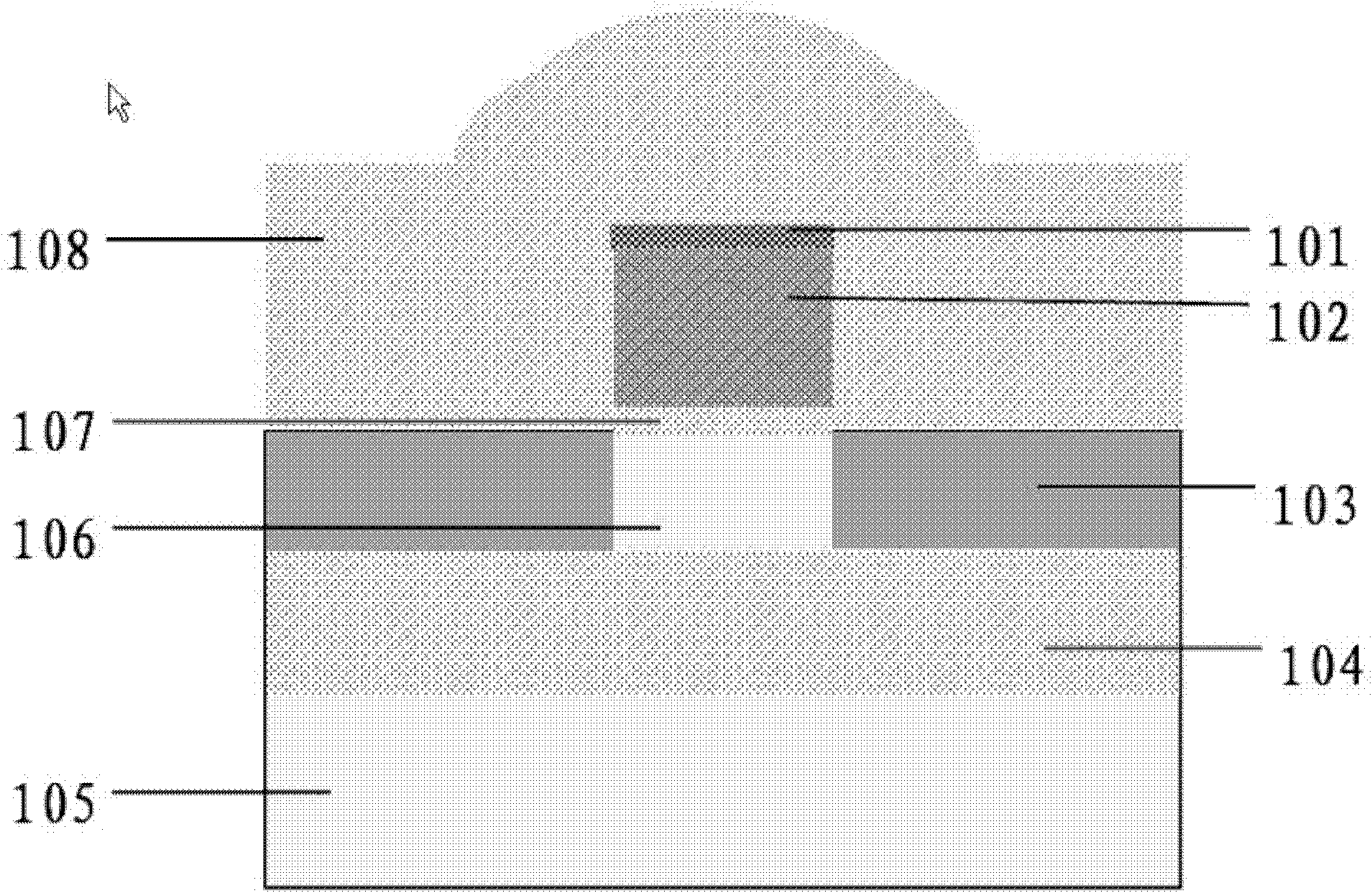

[0023] The temperature testing method of the present invention mainly includes a PN junction formed by a top material layer and a polysilicon gate. The PN junction is directly located on the polysilicon gate above the device channel, and the PN junction current increases in a quadratic relationship with temperature, so the temperature change of the device can be accurately reflected by monitoring the PN junction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com