Electromagnetic induction heating motor, heading system, and heating method

An electromagnetic induction heating and electromagnetic induction technology, applied in induction heating, induction heating devices, electric/magnetic/electromagnetic heating, etc., can solve problems such as heating wires, heating pipes are easily damaged, heating temperature is uneven, and heating parts heat up slowly. , to achieve the effect of controllable heating temperature, low processing cost and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments (embodiments). The specific embodiments described here are only used to explain the present invention, but not as a basis for limiting the present invention.

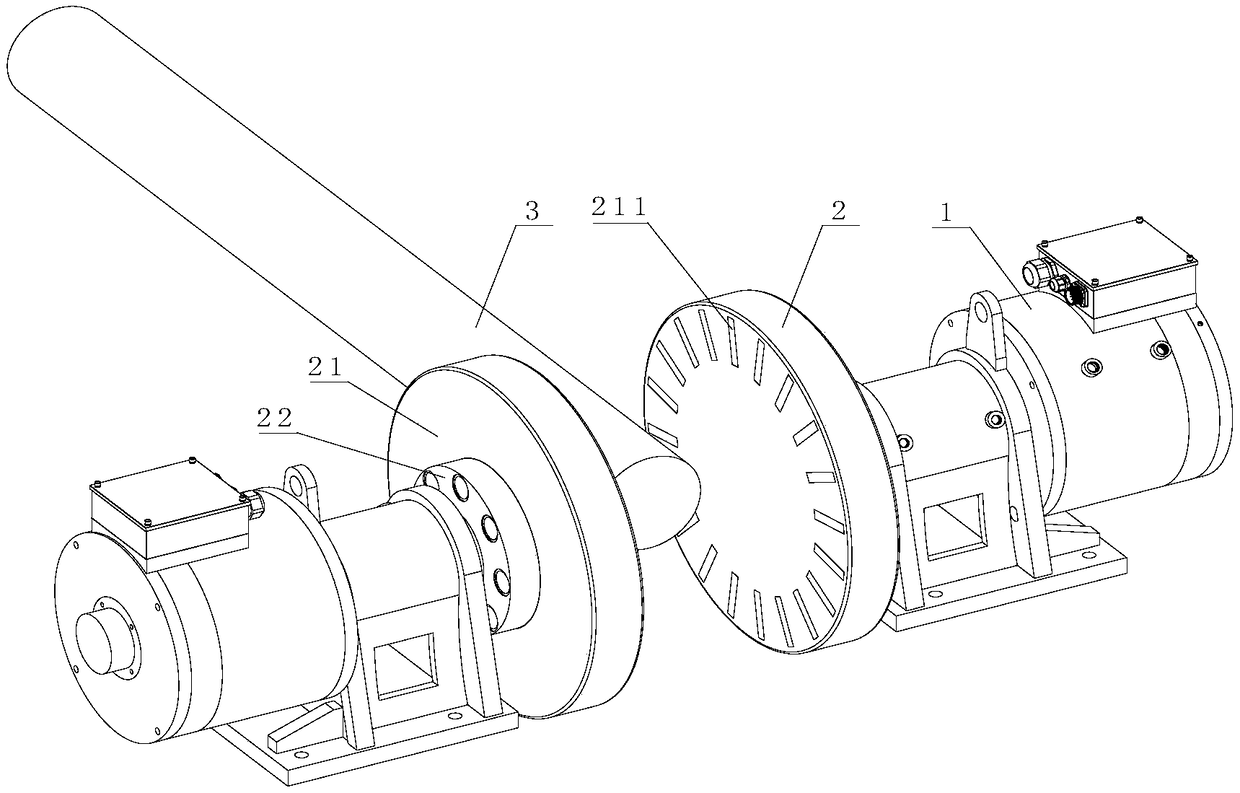

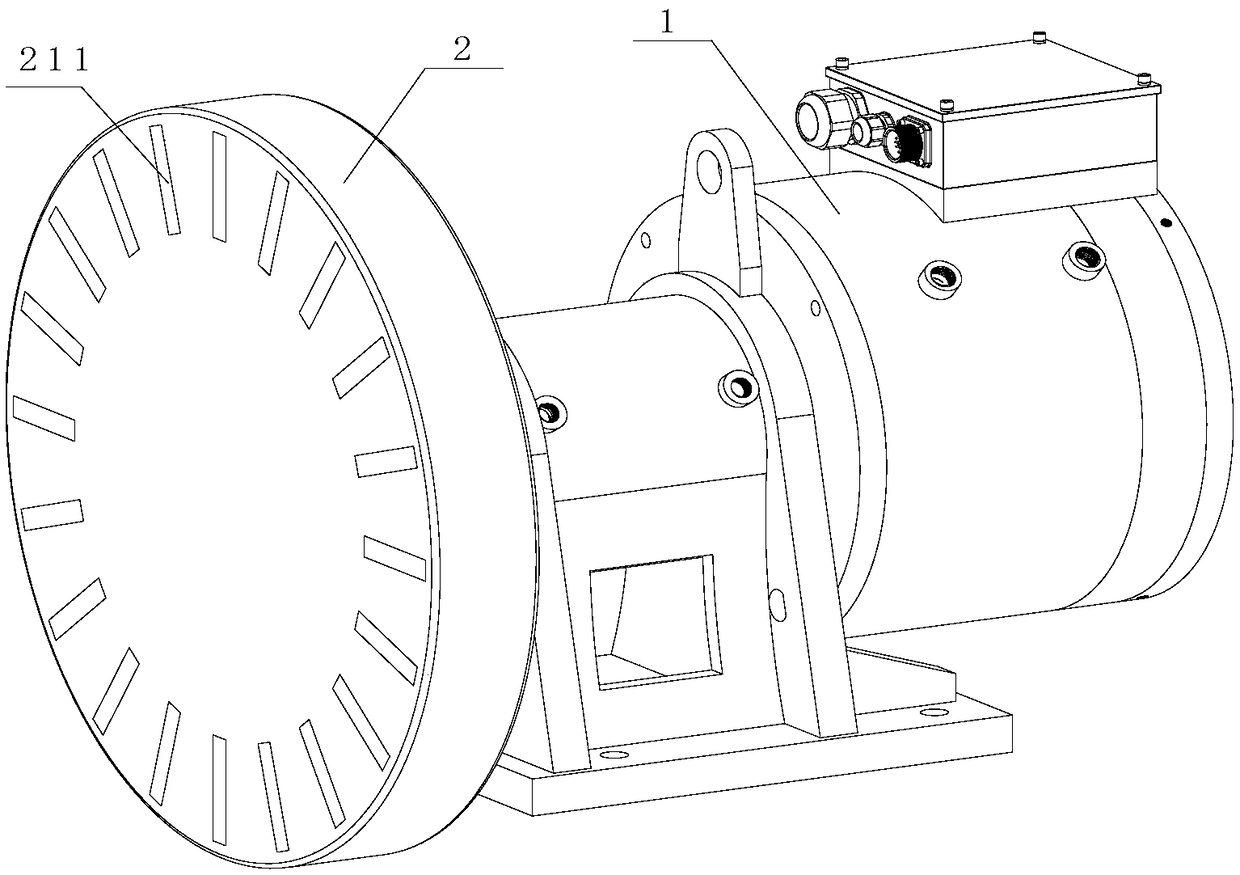

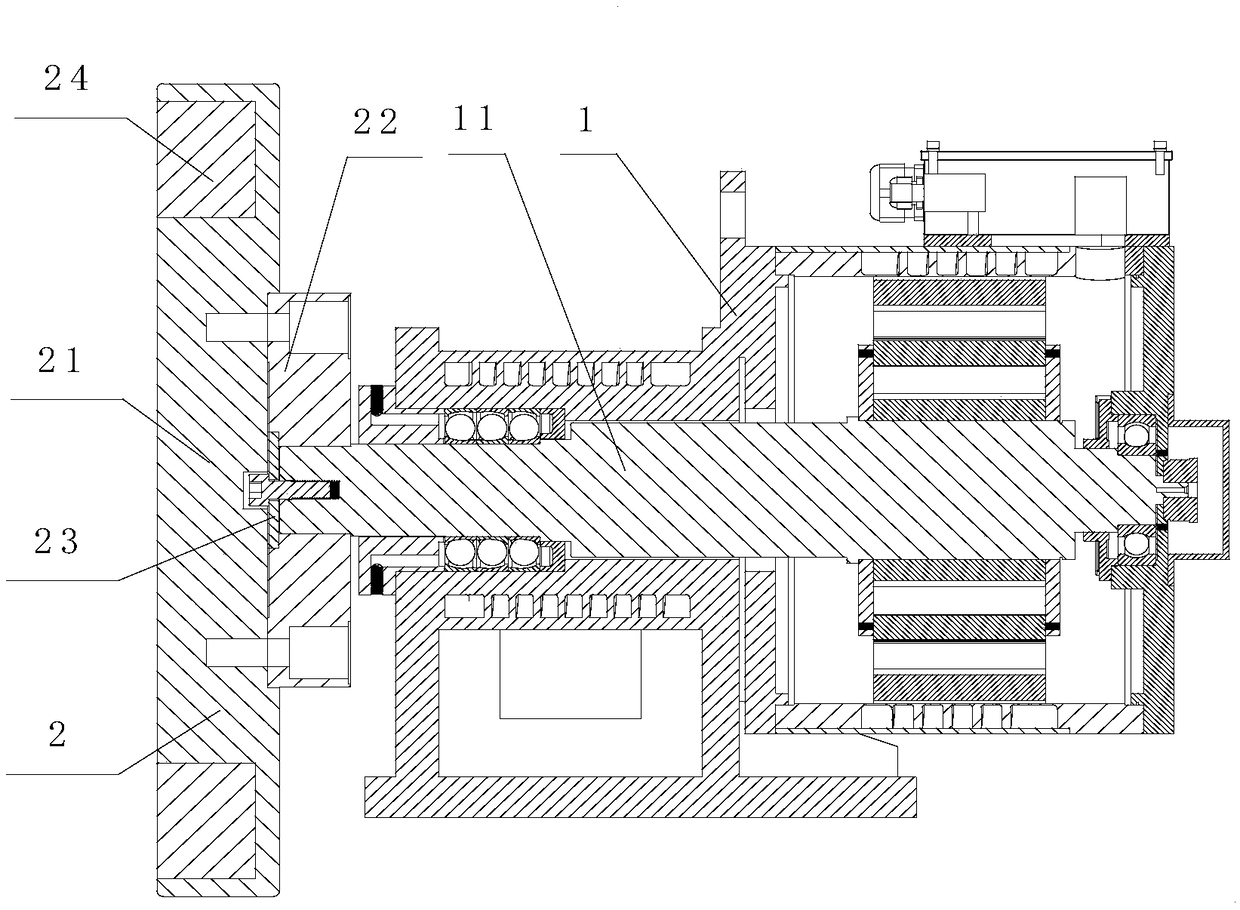

[0029] see Figure 1-3 , the electromagnetic induction heating motor of the present invention includes a motor body 1 and an electromagnetic induction heating device 2; And be connected to the driving turntable pressing plate 23 of the motor shaft and the electromagnetic induction disk 21 that is fixed to the outer end surface of the driving turntable 22; the electromagnetic induction disk 21 is evenly distributed with a plurality of rectangular grooves 211 along the circumferential direction, and the rectangular The center line of the slot 211 points to the center of the electromagnetic induction disk 21, forming a radial arrangement, and the slot is provided with N-level or S-level magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com