Minitype electric heating plate and manufacturing method thereof

A manufacturing method and technology for electric heating plates, which are applied in electric heating devices, ohmic resistance heating, chemical instruments and methods, etc., can solve problems such as harmful carcinogens to the human body, and achieve the effects of low price, easy assembly, and improved radiation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The manufacture method of small electric heating plate of the present invention, it comprises:

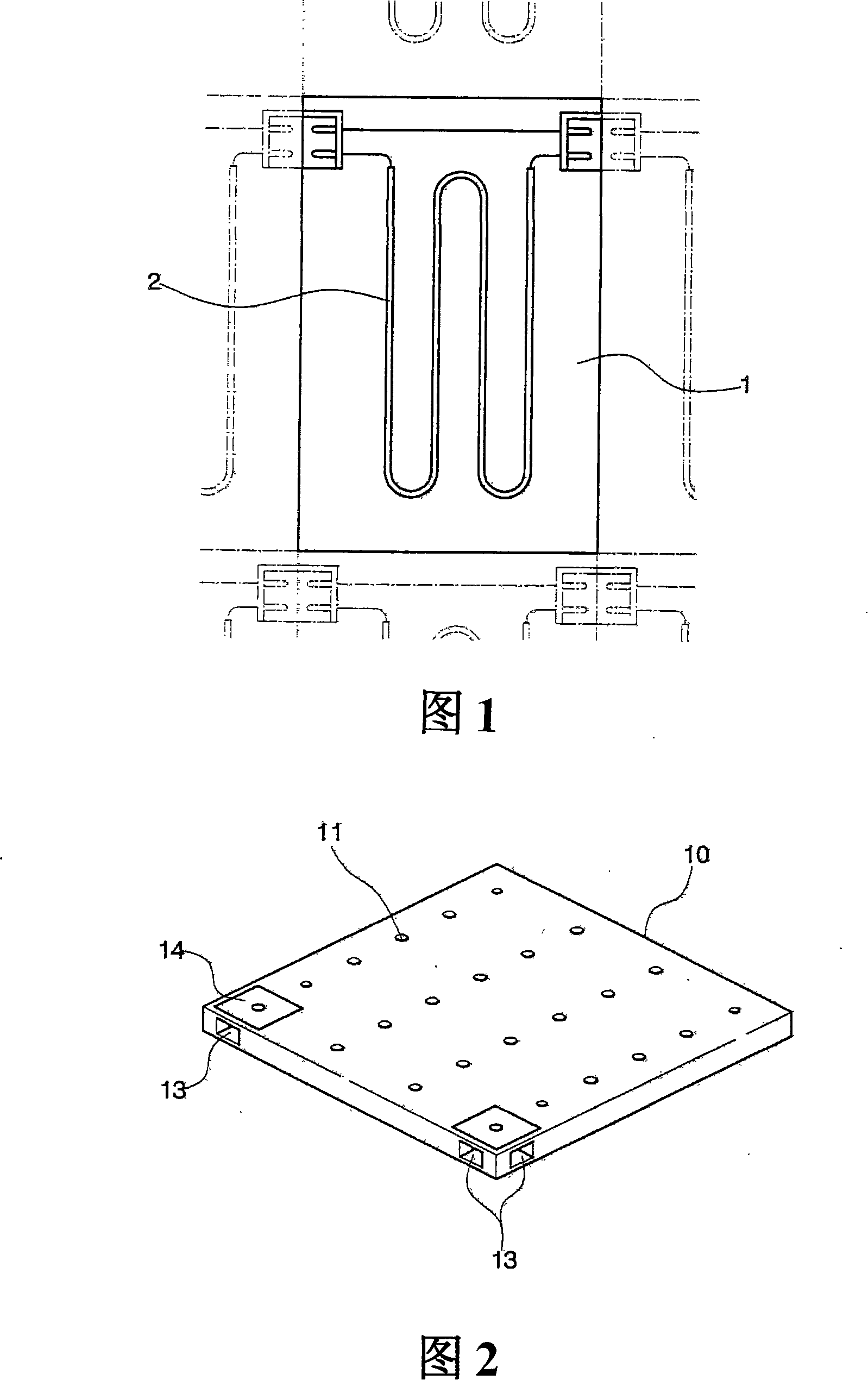

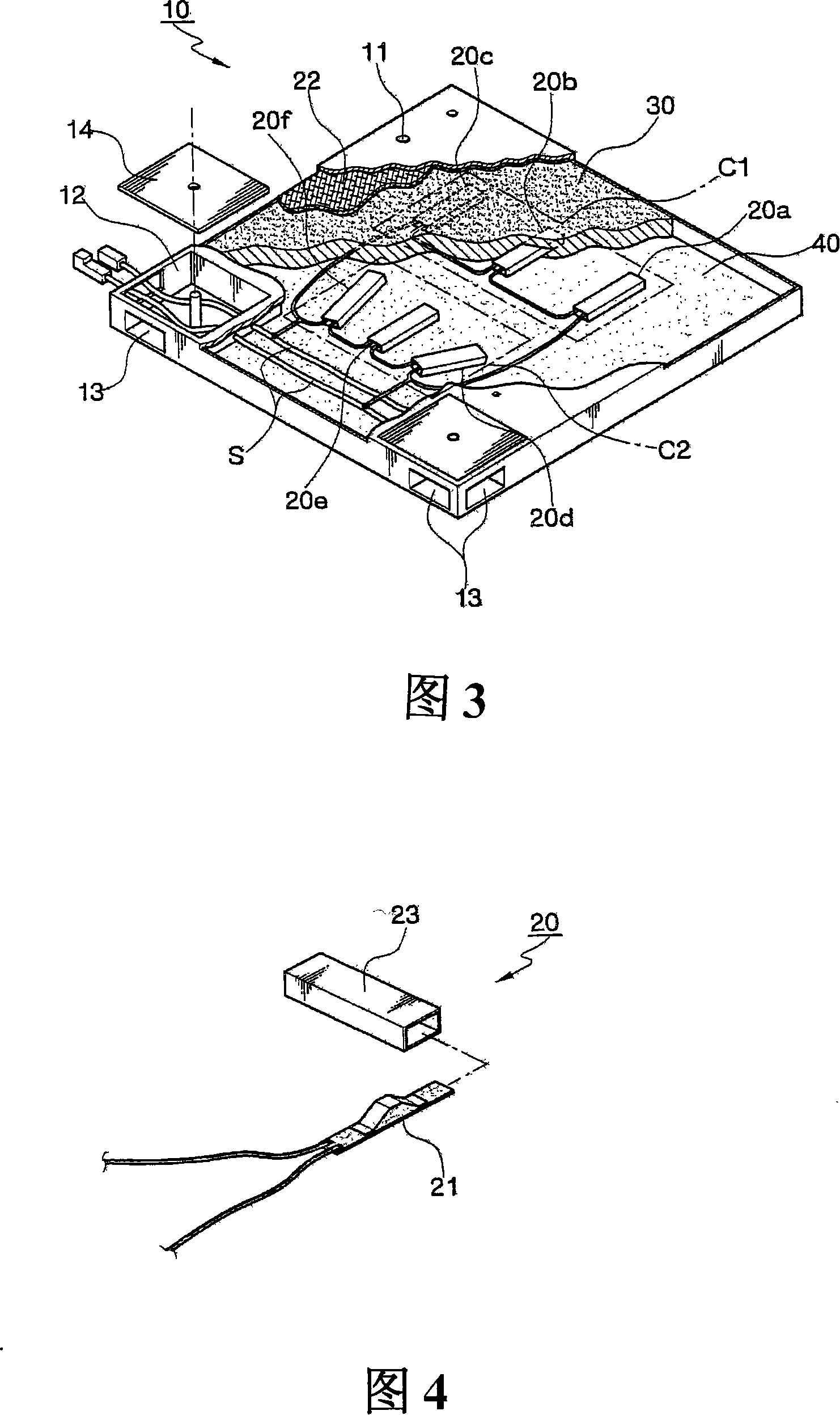

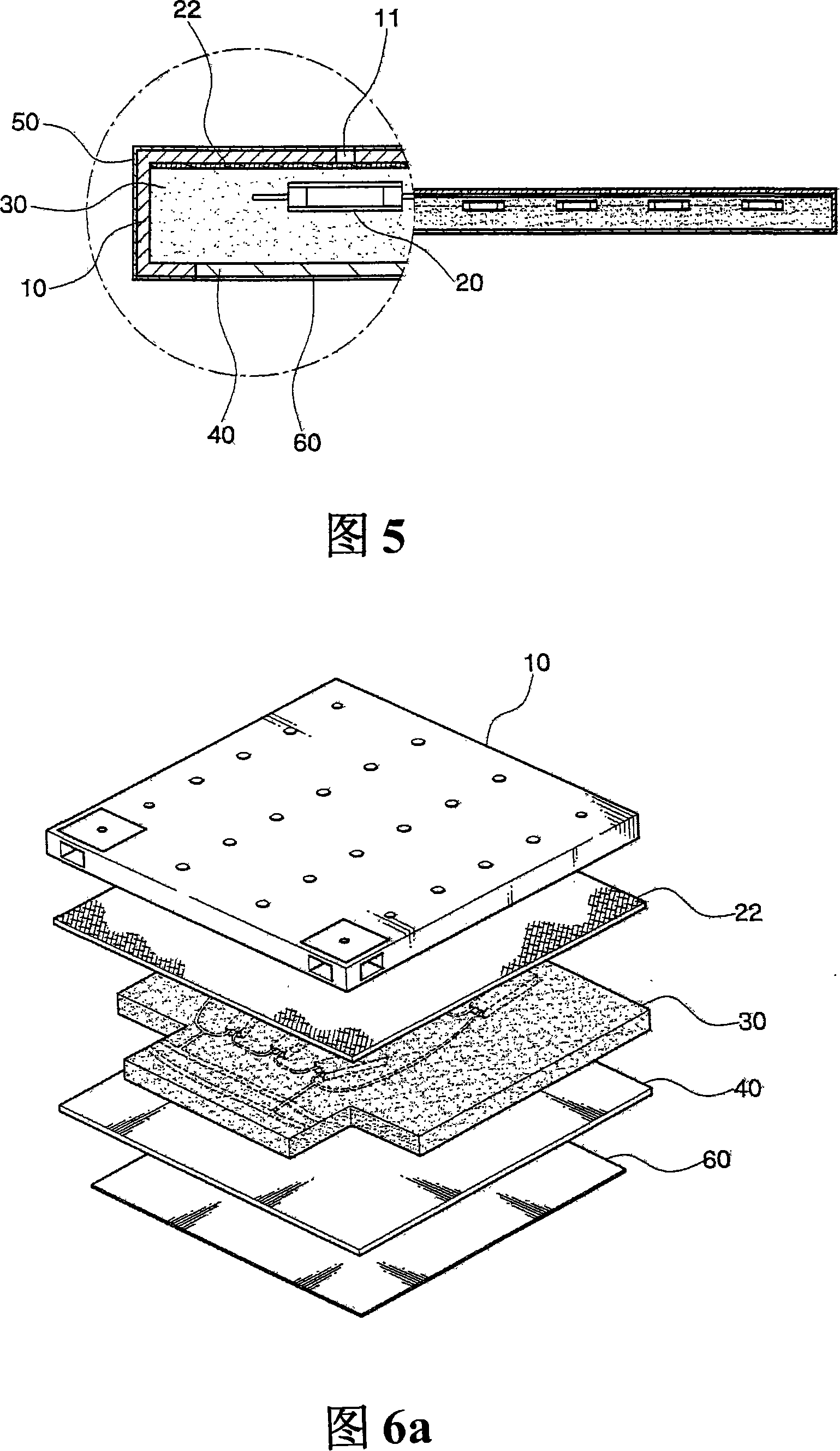

[0033] Cutting the antirust-treated metal plate into a square metal plate of a certain size, piercing at least two ventilation holes 11 on the metal plate cut into a square shape, and forming a junction box 12 and a channel 13 on one side of the metal plate, The four sides of the bending processing metal plate form the metal plate processing step 100 of the box-shaped plate 10; on the surface of the box-shaped plate 10, the paint containing the radiation material that can emit negative ions and far-infrared rays is coated to form the box of the far-infrared radiation layer 50. Template coating stage 200: a non-woven fabric 22 for preventing dust is arranged on the inner side of the box-shaped panel 10, and two sets of heating circuits C1 and C2 with at least two ceramic heating elements 20a-20f connected in series are formed, and then The ceramic heating element wiring stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com