Tool and method for simulating internal heating of composite insulator

A composite insulator and internal heating technology, which is applied in microwave heating, electric heating devices, electric/magnetic/electromagnetic heating, etc., can solve the problems of local heating of insulators, reappearing thermal aging process of insulators, mechanism obstacles of rotten fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

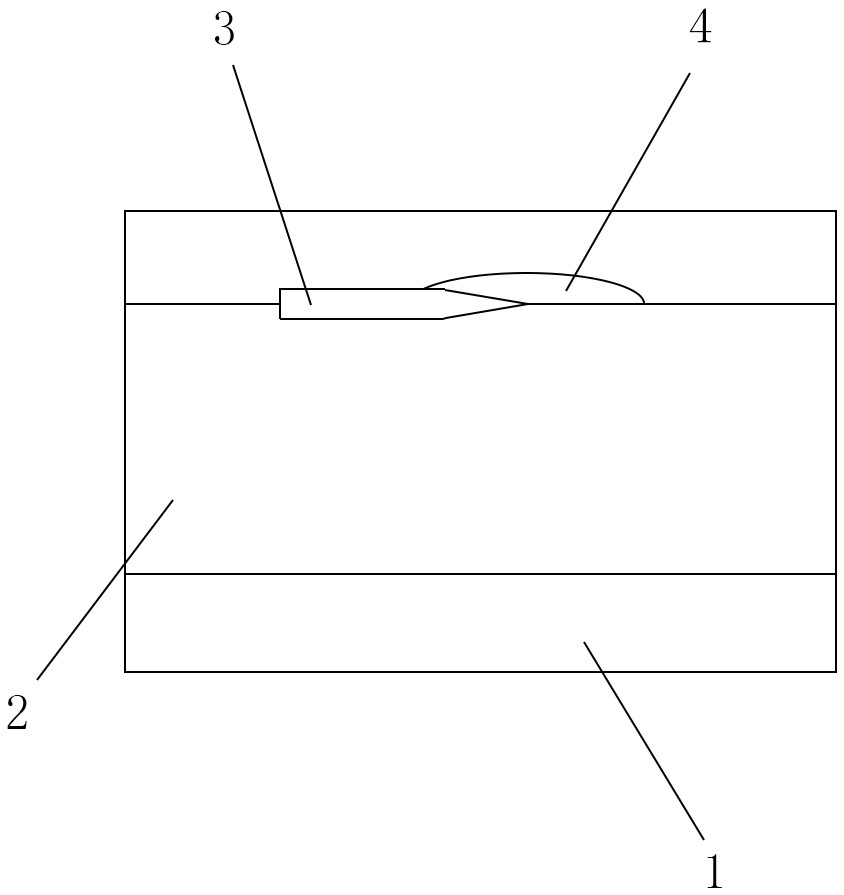

Image

Examples

Embodiment 1

[0019] According to the propagation law of electromagnetic waves in the medium, microwaves undergo transmission, scattering, and reflection processes when they are vertically incident on the medium. In the passive region of free space, the wave equation of the electromagnetic field can be transformed into a homogeneous Helmholtz vector equation:

[0020]

[0021] Among them, k0 is the free space wave number, E is the electric field component of the uniform plane electromagnetic wave,

[0022]

[0023] For the components Ex, Ey, and Ez of the vector E in three directions in the Cartesian coordinate system, they all satisfy the equation (1). For a uniform plane wave propagating in the +z direction, the phasor expression for the electric field strength is:

[0024]

[0025] where E 0 is a constant vector.

[0026] The propagation characteristics of electromagnetic waves in the dielectric are analyzed separately below. In order to facilitate the discussion of the prop...

Embodiment 2

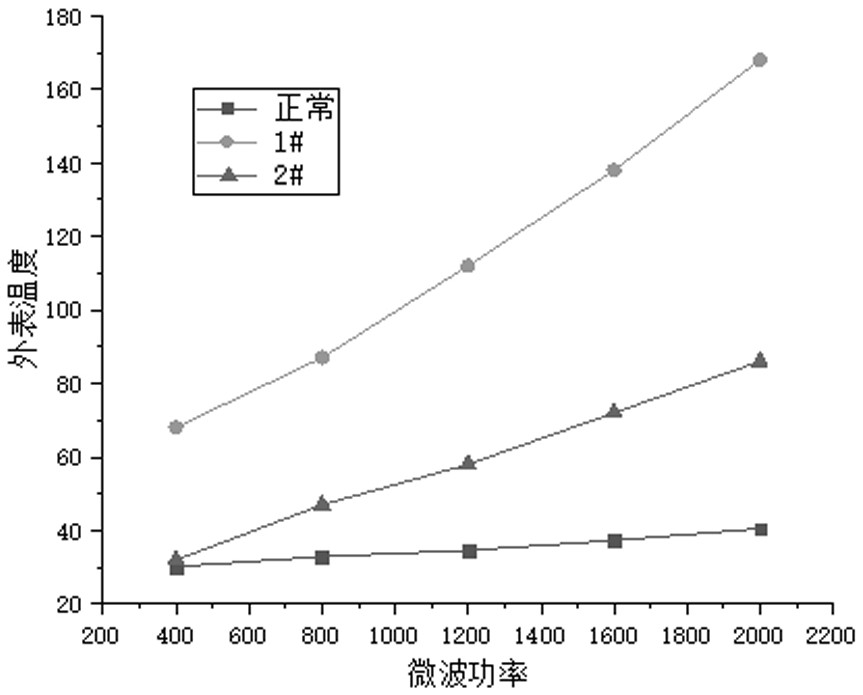

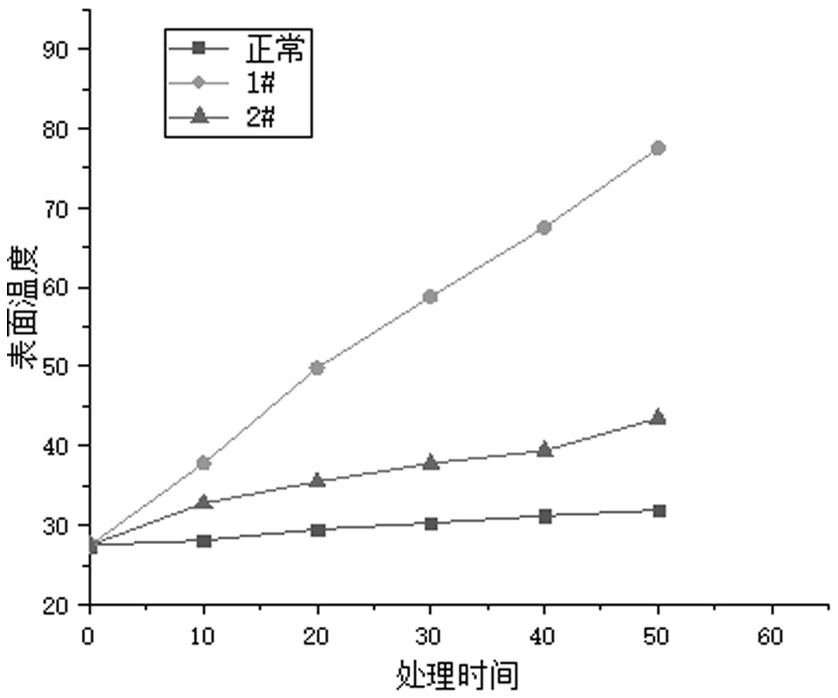

[0062] Two samples containing interface defects were cut from composite insulators that were heated at high temperature on site and named 1# and 2# respectively, with a length of about 200mm. The sample is heat-treated with microwaves. By adjusting the working gear and working time of the microwave oven, the microwave power and processing time acting on the insulator are changed, and the highest temperature on the surface of the insulator sample is recorded after the test. The control microwave output power is 400W, 800W, 1200W, 1600W, 2000W respectively, and the microwave action time is 10s, 20s, 30s, 40s, 50s, 60s respectively. #Using the infrared thermal imaging camera to observe the heating situation is as follows figure 2 image 3 shown.

[0063] With the increase of microwave power and heating time, the surface temperature of short insulators containing defects rises faster, while the surface temperature of normal insulators rises slowly. When the heating time reaches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long trail | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com