Application of cesium-tungsten bronze as welding flux for welding sapphire

A cesium tungsten bronze, a technology using cesium tungsten bronze, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of large stress in welding structure, large difference in thermal expansion coefficient, and decrease in bending strength of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Carry out surface polishing treatment to the cut sapphire wafer, make the sapphire surface roughness Ra be 3.000nm.

[0047] (2) The chemical formula of 55wt% is Cs 0.7 WO 3 The cesium tungsten bronze is mixed with the ethanol of 45wt%, obtains the cesium tungsten bronze slurry;

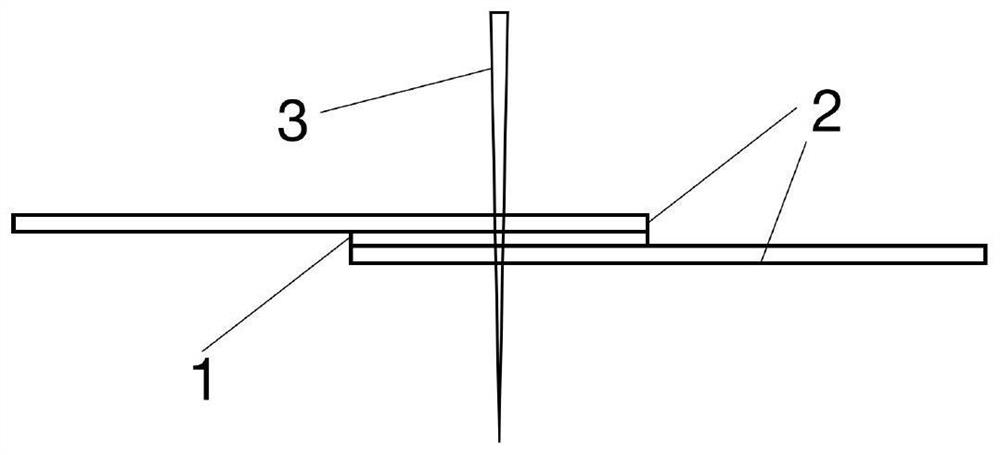

[0048] (3) Coating the cesium tungsten bronze slurry on the surface of the sapphire to be welded, and facing the two sapphire surfaces to be welded, and applying pressure so that the thickness of the cesium tungsten bronze in the weld seam is 30 μm;

[0049] (4) Use a molybdenum jig to clamp the sapphire, apply a pressure of 20N to the sapphire to be welded, set the heating target temperature of the heater to 800°C, heat up at a rate of 5°C / min, use a wavelength of 1050nm, a laser spot diameter of 2mm, and a power of 5000W The infrared laser is irradiated to the weld through one side of the sapphire for 5s, and then the power of the infrared laser is reduced at a rate of 200W / s until the...

Embodiment 2

[0053] (1) Carry out surface polishing treatment to the cut sapphire wafer, make the sapphire surface roughness Ra be 4.000nm.

[0054] (2) the chemical formula of 97wt% is Cs 0.8 WO 3 The cesium tungsten bronze is mixed with the ethanol of 3wt%, obtains the cesium tungsten bronze slurry;

[0055] (3) Coating the cesium tungsten bronze slurry on the sapphire surface to be welded, and facing the two sapphire surfaces to be welded, and applying pressure so that the thickness of the cesium tungsten bronze in the weld seam is 80 μm;

[0056] (4) Use a molybdenum jig to clamp the sapphire, apply a pressure of 50N to the sapphire to be welded, set the heating target temperature of the heater to 1200°C, heat up at a rate of 10°C / min, use a wavelength of 1050nm, a laser spot diameter of 10mm, and a power of 8000W The infrared laser irradiates the weld through one side of the sapphire for 30s, and then reduces the power of the infrared laser at a rate of 200W / s until the power of the...

Embodiment 3

[0060] (1) Carry out surface polishing treatment to the cut sapphire wafer, make the sapphire surface roughness Ra be 5.000nm.

[0061] (2) the chemical formula of 97wt% is Cs 0.8 WO 3 The cesium tungsten bronze is mixed with the ethanol of 3wt%, obtains the cesium tungsten bronze slurry;

[0062] (3) Coating the cesium tungsten bronze slurry on the sapphire surface to be welded, and facing the two sapphire surfaces to be welded, and applying pressure so that the thickness of the cesium tungsten bronze in the weld seam is 70 μm;

[0063] (4) Mount the sapphire with a molybdenum fixture, apply a pressure of 300N to the sapphire to be welded, set the heating target temperature of the heater to 700°C, heat up at a rate of 8°C / min, use a wavelength of 1050nm, a laser spot diameter of 3mm, and a power of 4000W The infrared laser is irradiated to the weld through one side of the sapphire for 20s, and then the power of the infrared laser is reduced at a rate of 200W / s until the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com