Low-temperature sintered nano silver paste and sealing method of sealing device

A technology of low-temperature sintering and nano-silver paste, which is applied in the manufacture of electric solid devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems that the safety and environmental performance of sealed devices cannot be guaranteed, the application and promotion are restricted, and the human body and the environment are harmful. To achieve the effect of simplifying the extraction and sealing process, reducing the thermal impact, and ensuring the tempering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

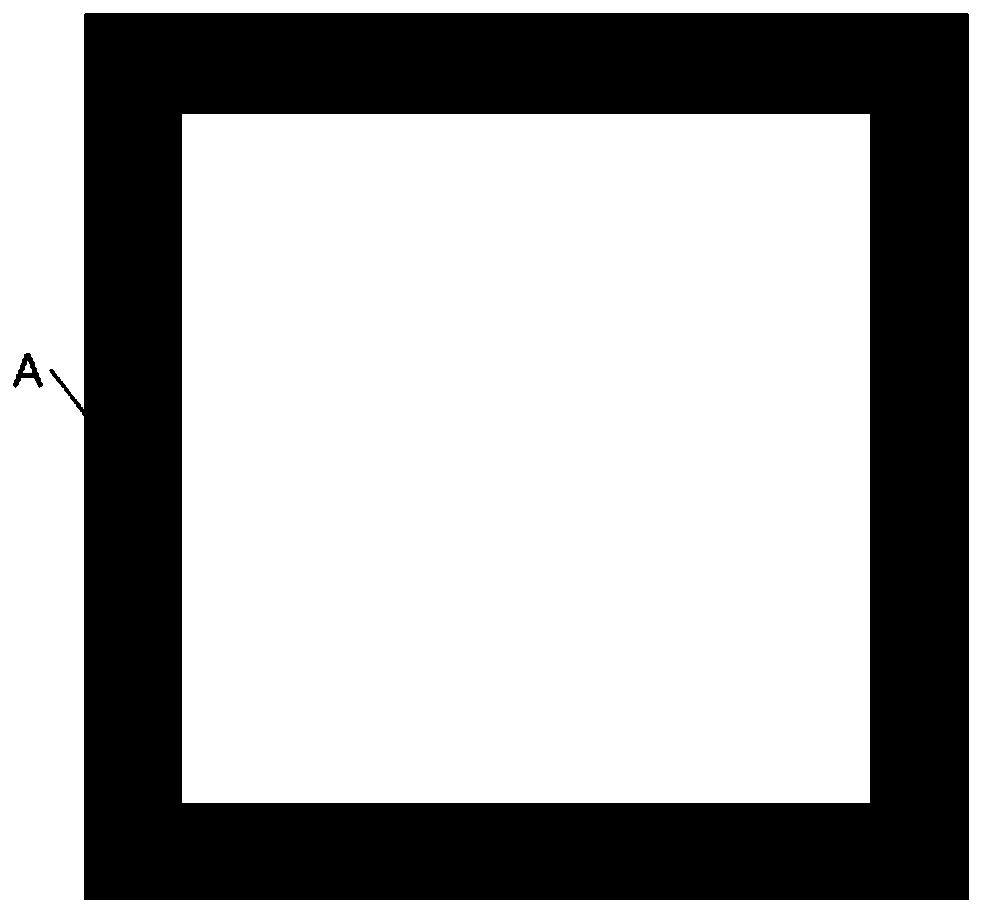

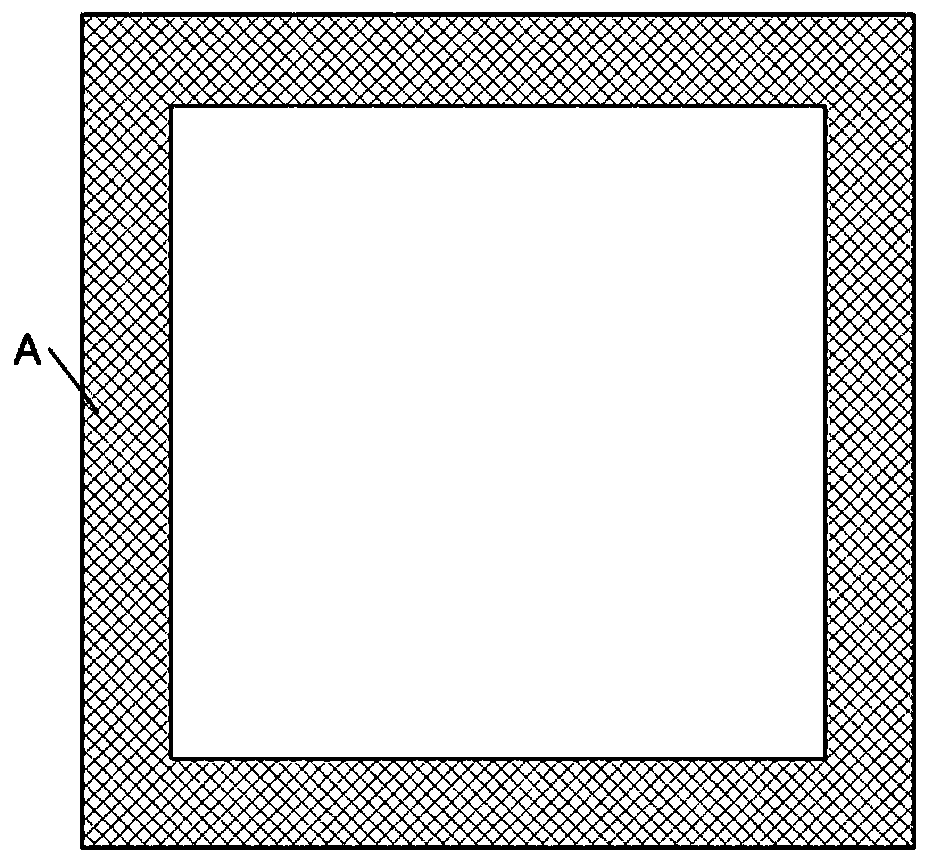

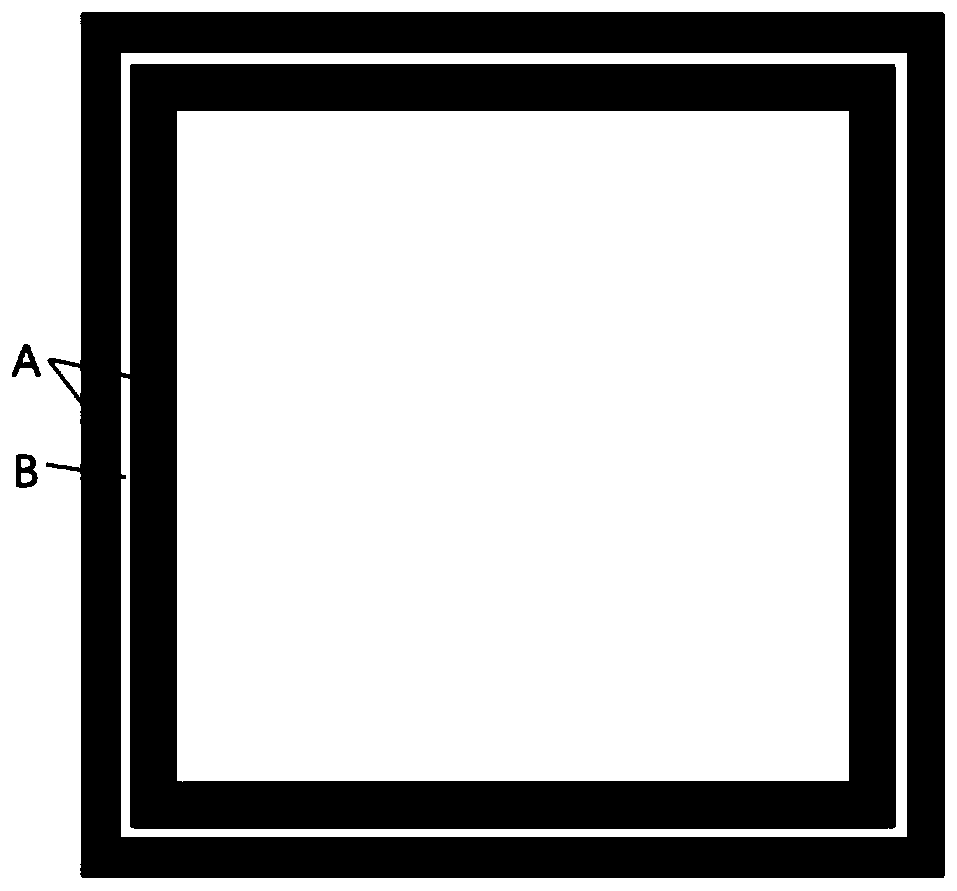

Image

Examples

Embodiment 1

[0040] This embodiment provides a low-temperature sintered nano silver paste and a sealing method for sealing devices, which specifically includes the following steps:

[0041] The self-made glass powder, 500nm spherical silver powder and mixed organic solvent are fully mixed according to a certain proportion, and the glass powder with a median diameter of about 2μm and the silver powder with a median diameter of about 500nm are spherical and The mixed organic vehicle is mixed in a ratio of 15:75:10, and the components contained in the mixed organic vehicle and their weight percentages are: α-terpineol 65%, ethyl cellulose 3%, ethyl acetate 15% , Ethylene glycol butyl ether 5%, diethylene glycol butyl ether acetate 3%, soybean lecithin 2% and antifoaming agent 7%, of which ethyl cellulose and soybean lecithin are dissolved in α-terpineol. It is prepared into a novel lead-free low-temperature sintered nano silver paste that can be printed on steel mesh or screen. The composition ...

Embodiment 2

[0049] This embodiment provides a low-temperature sintered nano silver paste and an efficient sealing method for sealing devices, which specifically includes the following steps:

[0050] The glass powder, 500nm spherical silver powder and mixed organic solvent are fully mixed according to a certain ratio to prepare a novel lead-free low-temperature sintered nano silver paste that can be printed on steel mesh or screen.

[0051] In terms of weight percentage, the glass powder with a median diameter of about 2μm and the silver powder with a median diameter of about 500nm are spherical in shape and mixed-type organic carriers are mixed in a mass ratio of 15:75:10, where the mixed-type organic carrier is mixed Contains α-terpineol 65%, ethyl cellulose 3%, ethyl acetate 15%, ethylene glycol butyl ether 5%, diethylene glycol butyl ether acetate 3%, soybean lecithin 2% and defoamer 7%, of which ethyl cellulose and soybean lecithin are respectively dissolved in α-terpineol. Wherein, the ...

Embodiment 3

[0057] On the basis of Example 1, the formulation of the low-temperature sintered nano-silver paste is different.

[0058] In terms of weight percentage, the glass powder with a median diameter of about 2μm and the silver powder with a median diameter of about 500nm are spherical in shape and mixed-type organic carriers are mixed in a mass ratio of 15:75:10, where the mixed-type organic carrier is mixed Contains α-terpineol 65%, ethyl cellulose 3%, ethyl acetate 15%, ethylene glycol butyl ether 5%, diethylene glycol butyl ether acetate 3%, soybean lecithin 2% and defoamer 7%, of which ethyl cellulose and soybean lecithin are respectively dissolved in α-terpineol. Wherein, the composition and mole percentage of the glass powder are: Bi 2 O 3 40%, H 3 BO 3 50%, ZnO 10%.

[0059] The steps and process parameters of the sealing method of the sealed device are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com