Laser cladding repairing method for inner hole of rolling mill roller end shaft sleeve and composite device for laser cladding

A technology of laser cladding and repairing method, which is applied in the direction of metal material coating process, coating, etc., can solve the problem of poor processing performance of the repaired part of the fracture toughness repaired part of the bonding force between the clad layer and the substrate, welding clad layer and parts Weak bonding force of the substrate, limited use of the original design structure when changing the scale, etc., to achieve the effect of ensuring performance, reducing temperature gradient and stress-strain unevenness, and strong repairability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

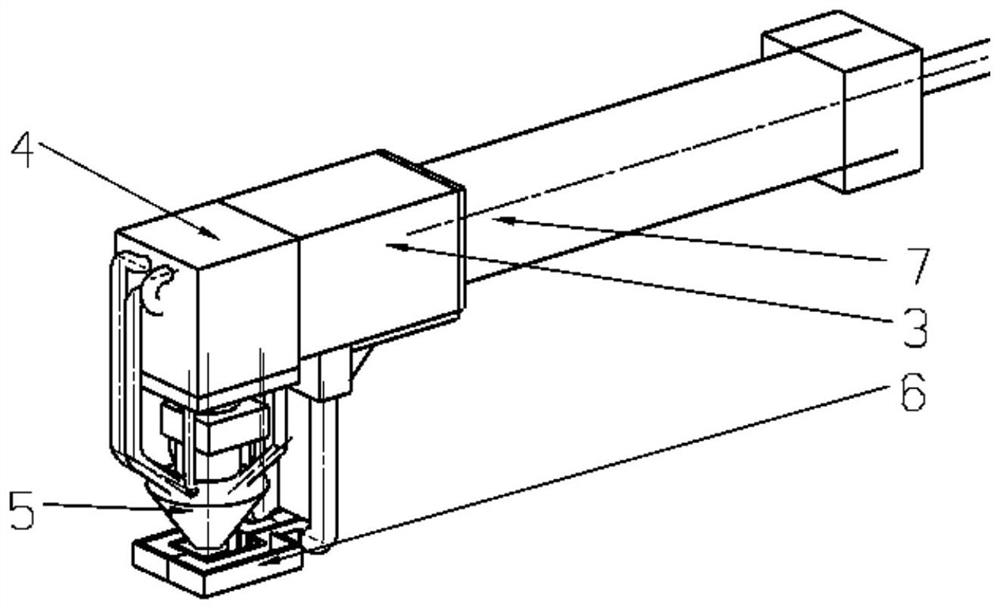

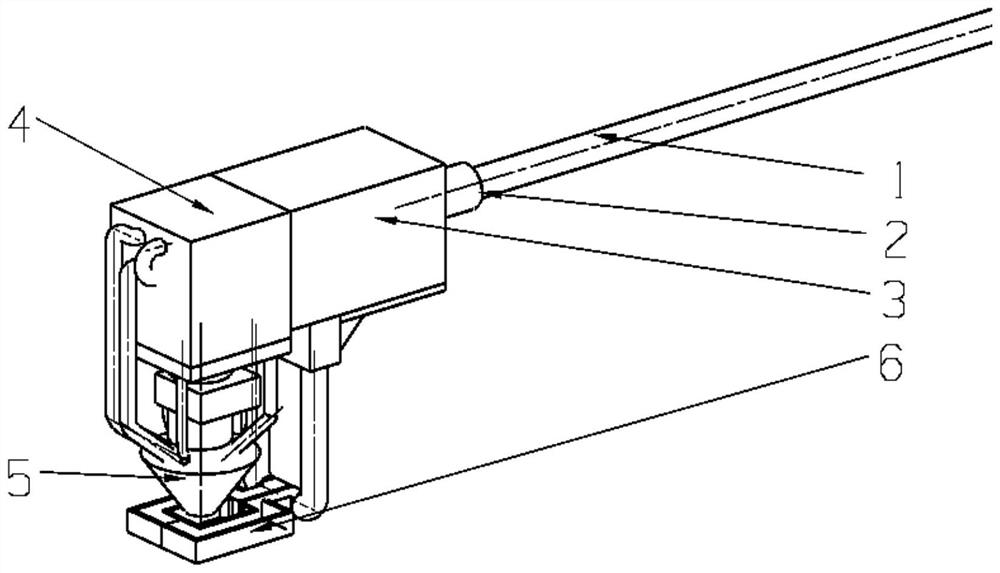

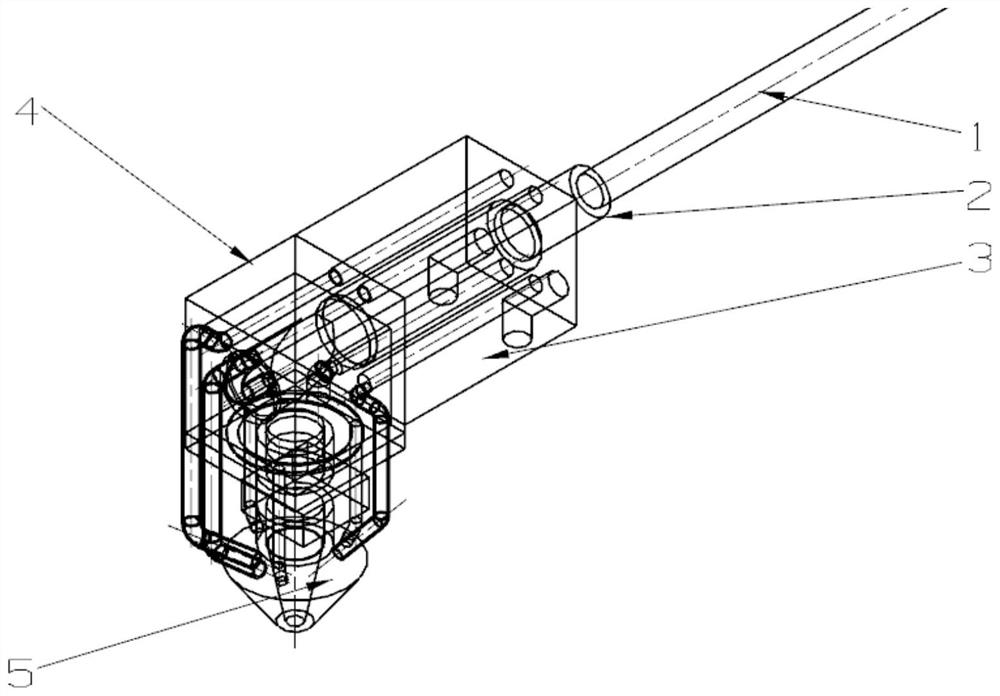

Method used

Image

Examples

Embodiment 1

[0054] The roller roller end shaft is 42CrMO, and the surface hardness HB269-302 is designed. After use in 1 year, the working surface wear is destroyed, and the performance of similar materials is required, restore the original size and performance indicators.

[0055] 1 Piecelet assembly dismantling: sequentially dismantling the assembly to ensure that the parts are not damaged, and the spare is stored;

[0056] 2 Cleaning of the shaft sleeve: Clean the surface of the bushing, remove oil, rust. Processing removal of the fatigue layer to be repaired to repair the working surface and exclude local defects, remove layer thickness 3-5mm, and perform 100% Pt flaw detection of the working surface;

[0057] 3 ingredient detection: use the mobile spectrometer to chemical composition analysis of the bushing, combined with the matrix material and the technical requirements for repair alloy materials;

[0058] 4 Pre-pre-heat treatment: the roller end shaft to be repaired is placed in the h...

Embodiment 2

[0065] The roller roller end shaft set is 25Cr2Ni4mov, the surface hardness HRC42-45 is designed. After use 1 year, the wear wear is long, requiring the use of similar materials to repair, restore the original size and performance indicators.

[0066] Among them, step 5 Working surface: The molten alloy material uses a soft powder + transition powder; select a semiconductor laser having a working wavelength of 900-1080 nm as a machining source, and outputs a flat spot spot laser beam; select the core of 1000 μm fiber transmission laser beam; The use of laser molten composite devices for sensing heating and desert; process parameters at the time of cladding: the spot size φ5mm, laser power 2.2kW-2.8KW, induction heating energy consumption percentage 10% -100%, scanning speed 600-720 mm / MIN, the paste is 2.5mm, the layer thickness is 1.2mm to 1.5mm. The rest is the same.

Embodiment 3

[0068] The roller roller end shaft set is 42CrMo, and the surface hardness HRC52-58 is designed. After use in 1 year, the working surface wear is extremely deviation, and the performance of similar materials is required to restore the original size and performance indicators.

[0069] Among them, step 4 Pre-heat treatment: placed the roller end shaft to be repaired in the heat treatment oven for annealing, the temperature rise rate is <100 ° C / h, the annealing temperature 550 ° C-600 ° C, the inclusion length is 4 h, and the curve is slow to room temperature Preheating before the cladding, the preheating temperature of 350 ° C to 400 ° C, using the induction heating device in the laser molten composite device for heating. Among them, step 5 Working surface is cleaved: alloy materials use soft powder + transition powder + strengthening powder; semiconductor laser having a working wavelength of 900-1080 nm as a machining source, output flat top spot laser beam; select the heart di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com