Medium-frequency induction heating furnace for heating lashing bar, and method

A technology of induction heating furnace and binding rod, which is applied in the direction of induction heating, induction heating control, coil device, etc., can solve the problems of increasing production cost, reducing product quality, and destroying metallographic structure, so as to save energy and improve heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

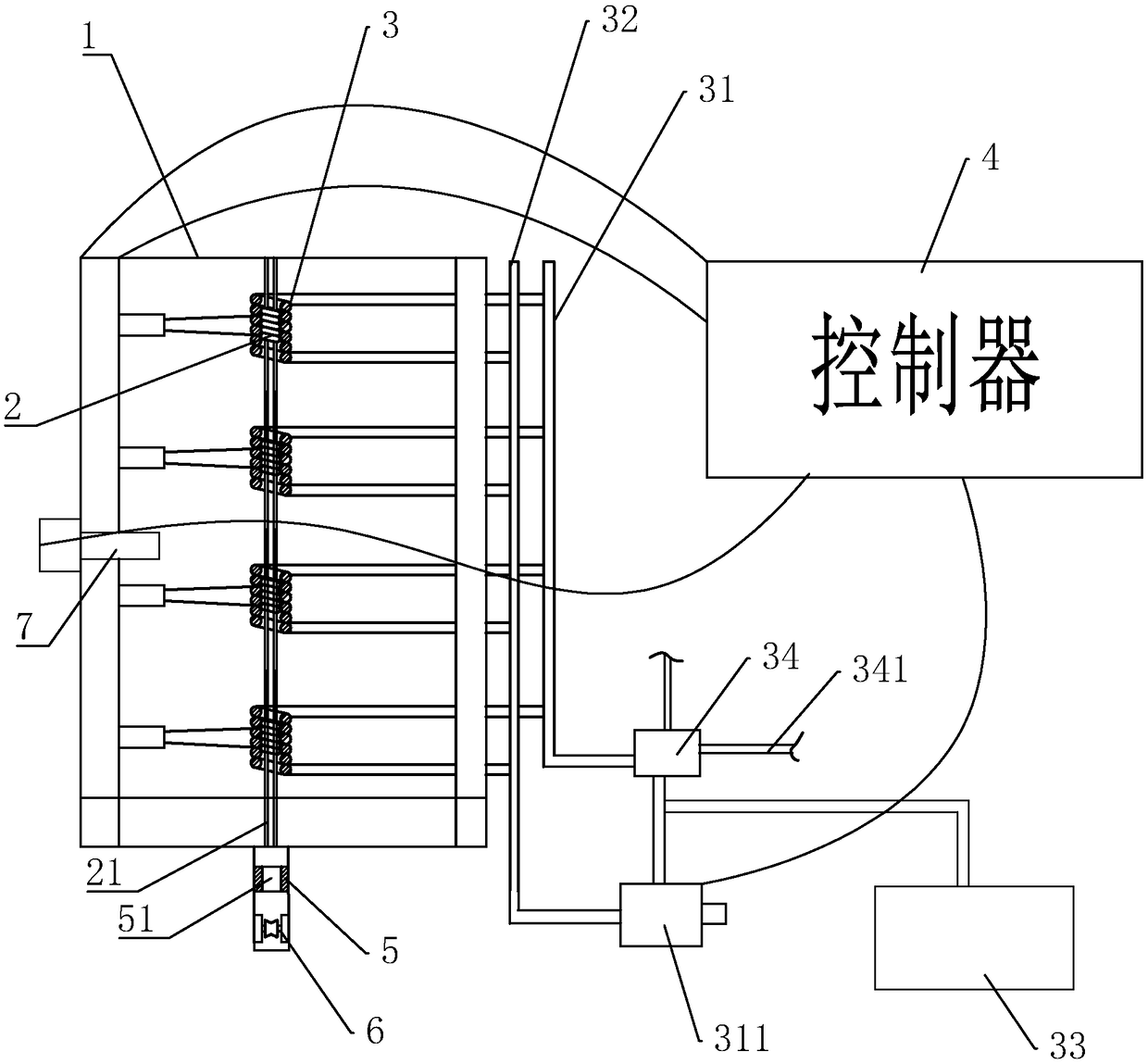

[0026] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0027] The present invention aims to provide a medium-frequency induction heating furnace for heating binding rods, such as figure 1 As shown, it includes a base 1, on which a plurality of induction coils 2 are coaxially arranged, the induction coils 2 are connected with a controller 4 and connected to a power supply, and a cooling water circulation pipeline 3 is arranged outside the induction coil 2, and the The input end of the cooling water circulation pipeline 3 is commonly connected with a water inlet pipe 31, the water inlet pipe 31 is connected with a water pump 311, and the output end of the cooling water circulation pipeline 3 is commonly connected with a water outlet pipe 32, and the water outlet pipe 32 is connected with the water pump 311, and the water pump 311 A replenishing water tank 33 is connected; a heat exchanger 34 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com