Novel tempering technology adopted after high-speed steel quenching

A high-speed steel, a new type of technology, applied in the field of new tempering process, can solve the problems of slow bainite transformation, long time spent, disproportionate harvest, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

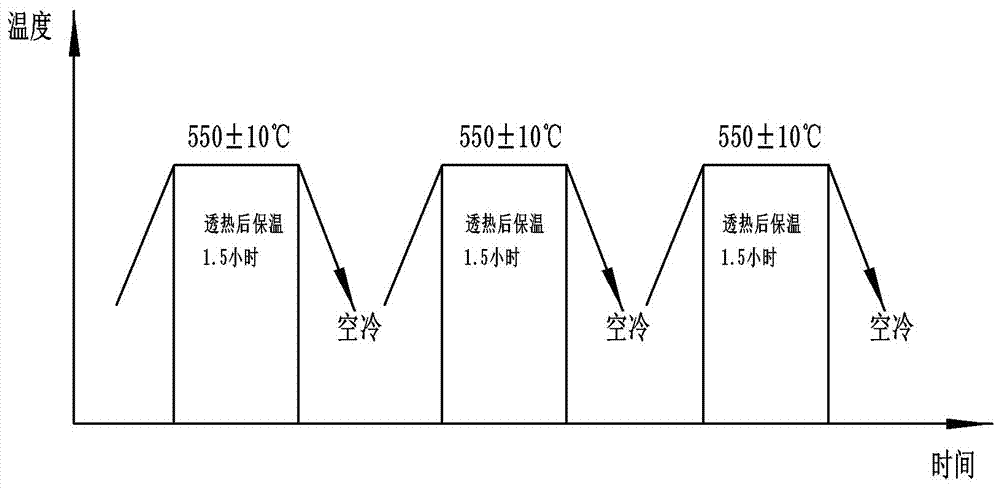

[0032] A novel tempering process for high-speed steel after quenching, comprising the following steps:

[0033](1) Heat the M2 high-speed steel to 1210°C to austenitize the product, keep it warm for 8 minutes, and then cool it to 50°C;

[0034] (2) Tempering for the first time: After step (1) is completed, heat the product to 250°C, keep it warm for 80 minutes, then quench the water, and cool it in water for about 10 minutes to reduce the temperature of the product to 20-30°C;

[0035] (3) Second tempering: After the first tempering, heat the product to 250°C again, keep it warm for 80 minutes, then quench the water, and cool it in water for about 10 minutes, so that the temperature of the product drops to 20-30°C;

[0036] (4) The third tempering: After the second tempering, heat the product to 520°C, keep it warm for 80 minutes, and then air cool.

Embodiment 2

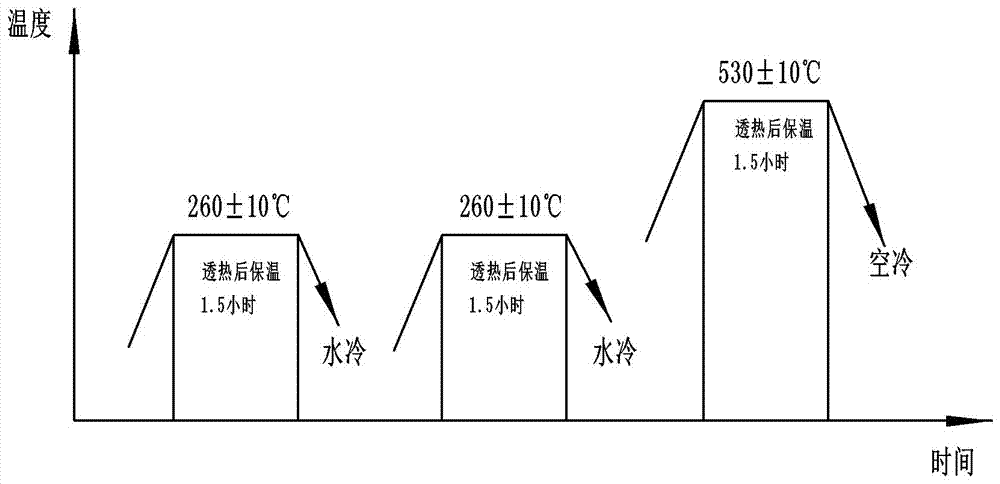

[0038] A novel tempering process for high-speed steel after quenching, comprising the following steps:

[0039] (1) Heat the M2 high-speed steel to 1220°C to austenitize the product, keep it warm for 10 minutes, and then cool it to 80°C;

[0040] (2) Tempering for the first time: After step (1) is completed, heat the product to 260°C, keep it warm for 90 minutes, then quench the water, and cool it in water for about 10 minutes to reduce the temperature of the product to 20-30°C;

[0041] (3) Second tempering: After the first tempering, heat the product to 260°C again, keep it warm for 90 minutes, then quench the water, and cool it in water for about 10 minutes, so that the temperature of the product drops to 20-30°C;

[0042] (4) The third tempering: After the second tempering, heat the product to 530°C, keep it warm for 90 minutes, and then air cool.

Embodiment 3

[0044] A novel tempering process for high-speed steel after quenching, comprising the following steps:

[0045] (1) Heat the M2 high-speed steel to 1230°C to austenitize the product, keep it warm for 12 minutes, and then cool it to 125°C;

[0046] (2) Tempering for the first time: After step (1) is completed, heat the product to 270°C, keep it warm for 100 minutes, then quench the water, and cool it in water for about 10 minutes to reduce the temperature of the product to 20-30°C;

[0047] (3) Second tempering: After the first tempering, heat the product to 270°C again, keep it warm for 100 minutes, then quench the water, and cool it in water for about 10 minutes, so that the temperature of the product drops to 20-30°C;

[0048] (4) The third tempering: After the second tempering, heat the product to 540°C, keep it warm for 100min, and then air cool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com