Cutting tool and manufacturing method thereof

A cutting tool and coating technology, applied in the cutting tool and its manufacturing field, can solve the problems of decreasing coating hardness, limiting coating oxidation resistance and wear resistance, banner decomposition, etc. effect of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

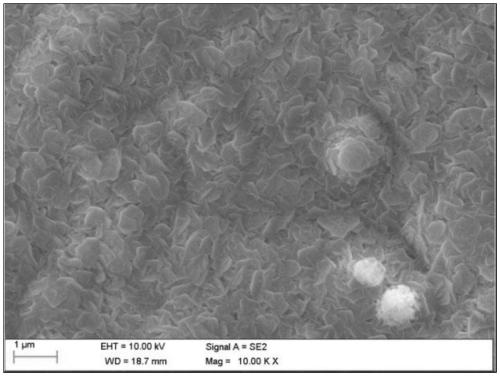

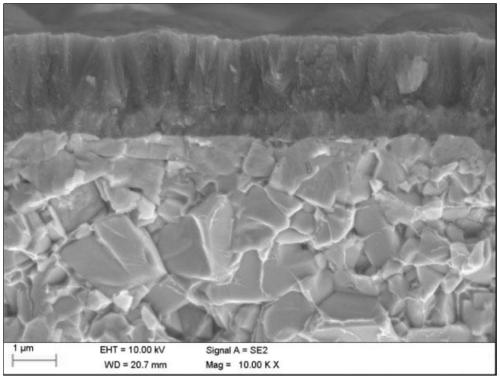

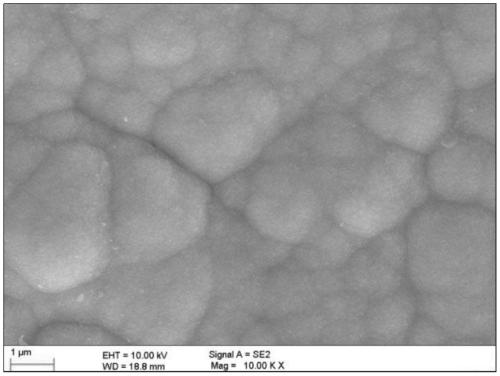

Image

Examples

Embodiment 1

[0051] Manufacturing cutting tools, in this embodiment, cutting tools are indexable inserts, prepared by the following steps:

[0052] A substrate is provided in the reaction site. In this embodiment, the substrate is a cemented carbide indexable insert. The composition of the cemented carbide includes 12% Co, 1.5% cubic carbide and the balance of WC. The model of bit blade is SNGX1206ANN-MM4;

[0053] (1) The first reaction gas is provided in the reaction place containing the cemented carbide indexable insert. In this embodiment, the first reaction gas is SiCl 4 , the silicon source is SiCl 4 , the proportion in the total reaction gas is 0.08%;

[0054] (2) The second reaction gas is provided in the reaction place containing the cemented carbide indexable insert. In this embodiment, the second reaction gas is AlCl 3 , the aluminum source is AlCl 3 , the proportion in the total reaction gas is 0.39%;

[0055] (3) Other reactive gases are provided in the reaction place tha...

Embodiment 2

[0062] In this embodiment, the cutting tool is an indexable insert, which is prepared through the following steps:

[0063] A substrate is provided in the reaction site. In this embodiment, the substrate is a cemented carbide indexable insert. The composition of the cemented carbide includes 8% Co, 1.6% cubic carbide and the balance of WC. The model of bit blade is SNGX1206ANN-MM4;

[0064] (1) The first reaction gas is provided in the reaction place containing the cemented carbide indexable insert. In this embodiment, the first reaction gas is SiCl 4 , the silicon source is SiCl 4 , the proportion in the total reaction gas is 0.18%;

[0065] (2) The second reaction gas is provided in the reaction place containing the cemented carbide indexable insert. In this embodiment, the second reaction gas is AlCl 3 , the aluminum source is AlCl 3 , the proportion in the total reaction gas is 0.39%;

[0066] (3) Other reactive gases are provided in the reaction place that accommodat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com