Plasma electrode and manufacturing method thereof

A technology of plasma electrode and manufacturing method, which is applied in the direction of plasma welding equipment, manufacturing tools, welding media, etc., can solve the problems of dispersed copper conductivity, unsatisfactory product appearance, increased product cost, long brazing time, etc., and achieve surface quality The effect of perfection, material cost reduction, and brazing time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

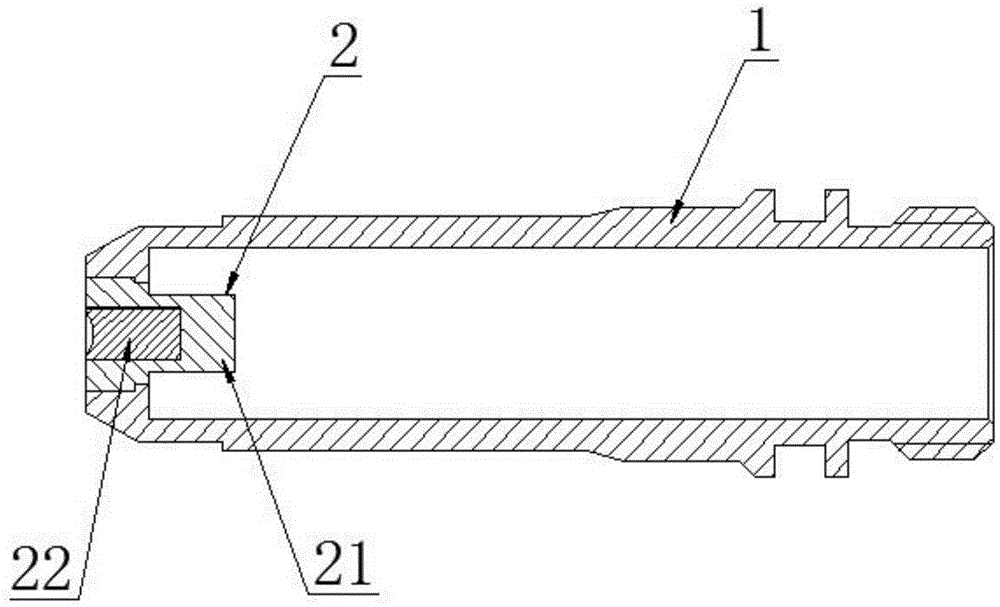

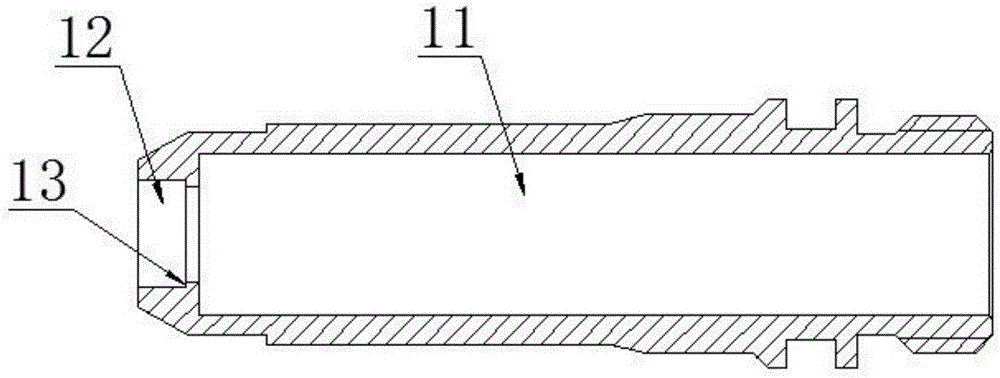

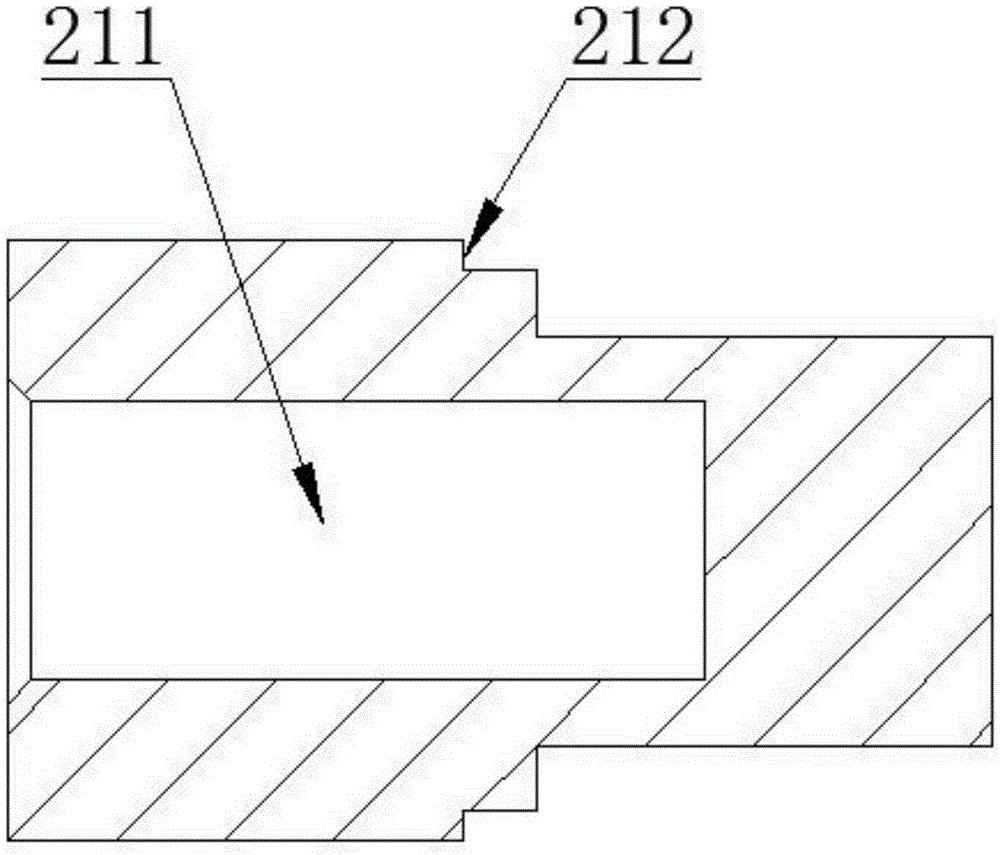

[0039] See Figure 1 to Figure 3 , The plasma electrode of this embodiment includes an electrode body 1 and a brazed inner core 2 .

[0040] The inside of the electrode body 1 is provided with a cooling hole 11 , and the head of the electrode body 1 is provided with an inner core hole 12 communicating with the cooling hole 11 . The brazed inner core 2 is welded in the inner core hole 12 of the electrode main body 1 . The brazed inner core 2 includes an electrode main body inner core 21 and an electrode emitter 22 . The material of the electrode emitter 22 is hafnium, zirconium, tungsten and the like. The inner core 21 of the electrode main body is provided with a brazing hole 211 . The electrode emitter 22 is brazed in the brazing hole 211 of the electrode body inner core 21 . The electrode body 1 and the electrode body inner core 21 of the brazed inner core 2 are all made of oxygen-free copper. The outer wall of the electrode main body inner core 21 of the brazing type i...

Embodiment 2

[0052] See Figure 6 This embodiment is basically the same as Embodiment 1, except that the outer limiting structure 212 of the inner core 21 of the electrode body and the inner limiting structure 13 of the electrode body 1 are wave-like structures that can be attached to each other.

Embodiment 3

[0054] See Figure 7 This embodiment is basically the same as Embodiment 1, except that the outer limiting structure 212 of the inner core 21 of the electrode body and the inner limiting structure 13 of the electrode body 1 are beveled structures that can be attached to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com