Method for preparing high-silicon silicon steel ribbon by hot dipping silicon method and continuous preparation device of silicon steel ribbon

A technology of hot-dip plating and thin strip, which is applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problem of lack of low-cost preparation of high-silicon steel sheet, affecting the surface quality of strip steel, and friction and scratches on the surface of steel and other problems to achieve the effect of avoiding processing difficulties, uniform thickness and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

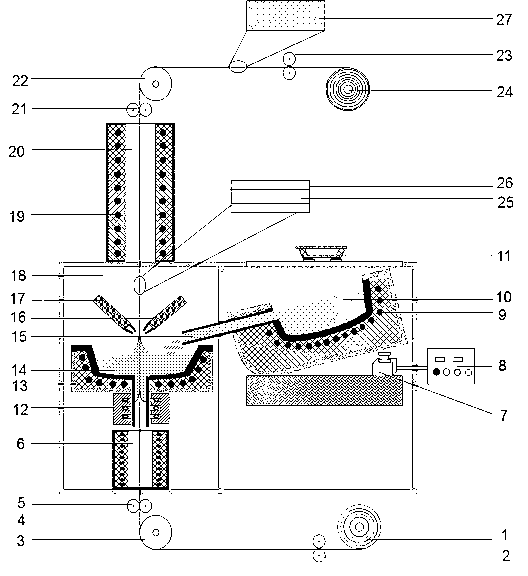

[0030] In this example, see figure 1 , a continuous preparation device for silicon steel strips, mainly comprising an unwinding guide device, a preheating furnace 6, a continuous supply device for plating solution, a hot-dip plating device, a diffusion heat treatment device and a winding device arranged according to the sequence of processes, specifically:

[0031] Prepare the spare basic strip 4 of the high silicon silicon steel strip by using the low silicon steel strip or the pure iron strip as the hot-dip silicon plating method, and roll the continuous spare basic strip 4 on the reel to form the spare basic strip roll 1 , the unwinding guiding device includes the unwinding conveying roller 2 of the spare base thin strip roll 1, the pretreatment guide pulley 3 and the pretreatment conveying roller 5, after the spare base thin strip 4 is uncoiled and drawn out by the unwinding conveying roller 2, it bypasses the pretreatment The guide pulley 3 continues to transport the spar...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, especially in that:

[0039] In this embodiment, the preheating furnace 6, the reserve molten pool device and the hot-dip coating device are placed in an insulated airtight room, and the waste heat recovery device will collect The thermal energy is transmitted to the diffusion heat treatment device as an auxiliary heat source for the uniform temperature field in the furnace chamber of the heat treatment furnace 20 . In this embodiment, the waste heat of the hot-dip coating process is used as an auxiliary heat source for the heat treatment of the high-silicon composite coated steel strip blank, so as to realize the recovery and utilization of waste heat and save energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com