Rail wheel tread scratch detection method

A detection method and technology of train wheels, applied in the detection field, can solve the problems of high false alarm rate, inability to clearly distinguish defects and dirt on tread surfaces, etc., and achieve the effect of avoiding detection false alarms and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the invention clearer, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

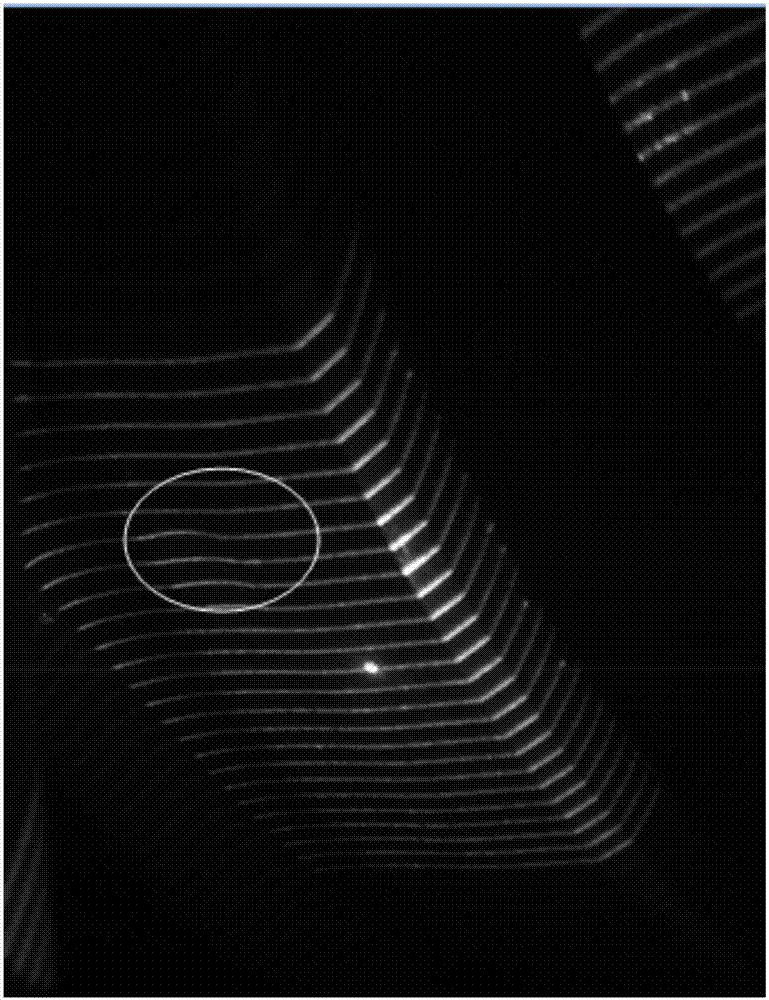

[0019] Such as Figure 1 to Figure 3 As shown, the present invention provides a method for detecting a train wheel tread scuff, which is used to detect train wheel tread defects and distinguish tread defects and tread dirt. The train wheel tread scuff detection method includes the following steps:

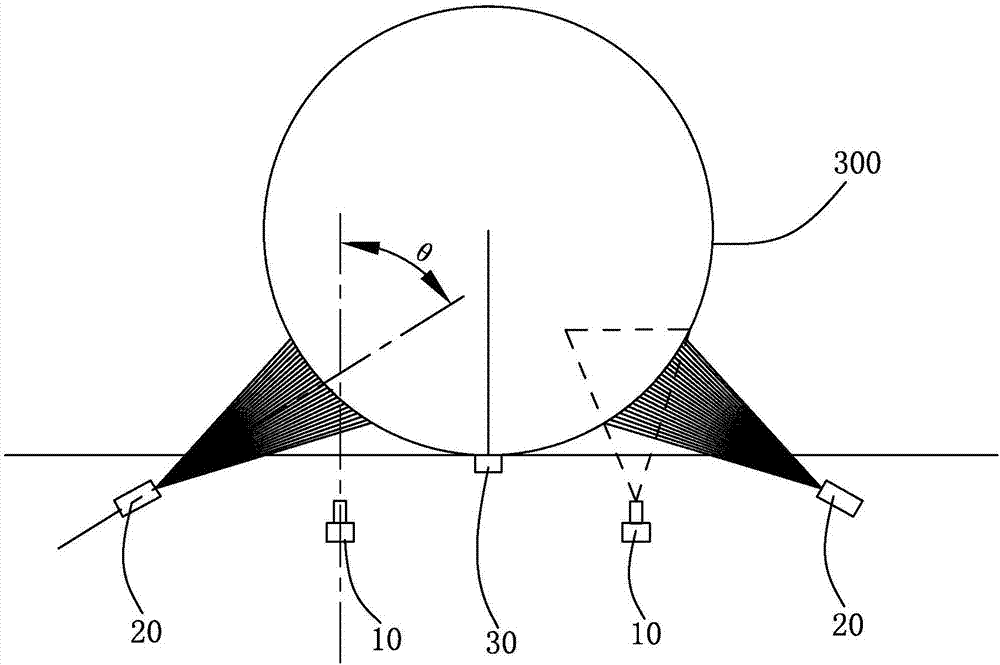

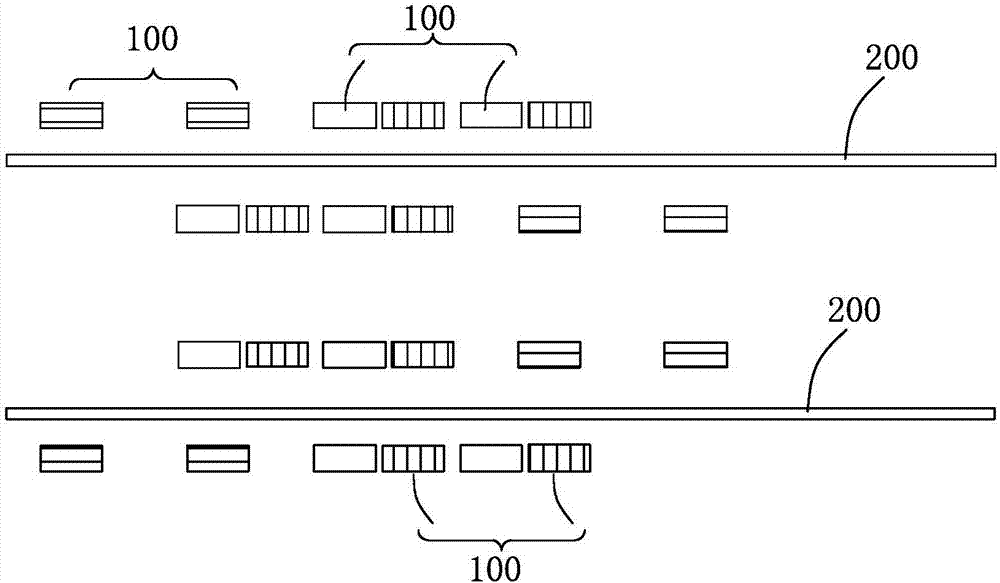

[0020] Step (1), image acquisition, provides an imaging device, the imaging device includes several imaging modules 100, each imaging module 100 includes two industrial cameras 10, two multi-line lasers 20 and a wheel alignment sensor 30, two The industrial cameras 10 are arranged on both sides of the wheel alignment sensor 30, and the two industrial cameras 10 are used in conjunction with the wheel alignment sensor 30. The wheel alignment sensor 30 can simultaneously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com