Super-hard copper-containing martensite antibiotic stainless steel

An antibacterial stainless steel and stainless steel technology, applied in the field of antibacterial stainless steel, can solve the problems of low hardness, low hardness, and no industrialization of stainless steel, and achieve the effect of superior antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

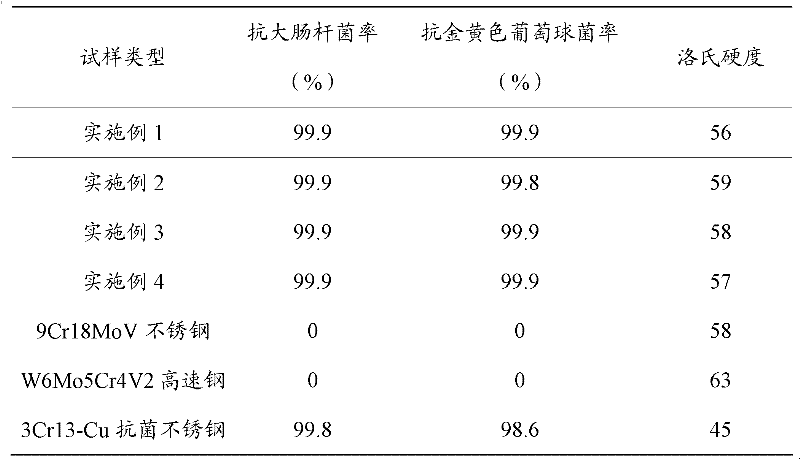

Embodiment 1

[0033] In terms of weight percentage, the chemical composition is: 0.8%C, 17%Cr, 3.0%Mo, 0.1%V, 2.0%W, 0.5%Ni, 3.5%Cu, 1.0%Re, 0.035%S, 0.01%P, 2.0% other impurity elements, the rest is Fe stainless steel vacuum induction furnace smelting, and then electroslag remelting to prepare metal ingots. The ingot was forged at 950°C to form a steel plate with a thickness of 20 mm, and then subjected to spheroidizing annealing at 850°C for 8 hours. Each steel plate was heated at 950° C. and hot-rolled to form a steel plate with a thickness of 3 mm. The steel plate is heated and kept at 700°C for 60 minutes, pickled with 3% dilute nitric acid, and then cold-rolled to produce a steel plate with a thickness of 0.5 mm.

[0034] The produced steel plate is heated at 1050°C for 20 minutes in a nitrogen atmosphere, then quenched in oil, and then tempered at 450°C for 2 hours to obtain the product.

Embodiment 2

[0036]In terms of weight percentage, the chemical composition is: 1.2%C, 18%Cr, 1.0%Mo, 0.6%V, 1.0%W, 3.0%Ni, 2.5%Cu, 0.1%Re, 0.025%S, 0.02%P, The stainless steel with 1.0% other impurity elements and the rest is Fe is smelted in an intermediate frequency induction furnace, and then electroslag remelted to prepare metal ingots. The ingot was forged at 1000°C to form a steel plate with a thickness of 100mm, and then subjected to spheroidizing annealing at 900°C for 18h. Each steel plate was heated at 900° C. and hot-rolled to form a steel plate with a thickness of 4 mm. The steel plate was heated and kept at 850°C for 40 minutes, pickled with 3% dilute nitric acid, and then cold-rolled to produce a steel plate with a thickness of 1.5 mm.

[0037] The produced steel plate is heated and kept at 1020°C for 60 minutes in an argon atmosphere, and then quenched in oil. After quenching, it is cryogenically treated with liquid nitrogen at -196°C for 5 hours, and then tempered at 500°C...

Embodiment 3

[0039] In terms of weight percentage, the chemical composition is: 1.0%C, 16%Cr, 2.0%Mo, 1.0%V, 3.0%W, 1.7%Ni, 3.0%Cu, 0.6%Re, 0.005%S, 0.03%P, 0.1% other impurity elements, the rest is Fe stainless steel vacuum induction furnace smelting, and then electroslag remelting to prepare metal ingots. The ingot was forged at 1100°C to form a steel plate with a thickness of 80 mm, and then subjected to spheroidizing annealing at 820°C for 24 hours. Each steel plate was heated at 1050° C. and hot-rolled to form a steel plate with a thickness of 5 mm. The steel plate is heated and kept at 900°C for 30 minutes, pickled with 3% dilute nitric acid, and then cold-rolled to produce a steel plate with a thickness of 2 mm.

[0040] The produced steel plate is heated and kept at 1000°C for 30 minutes in a nitrogen atmosphere, then quenched in oil, and then tempered at 465°C for 1 hour to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com