Double-nanostructure tungsten alloy with good high-temperature stability and preparation method and application thereof

A nanostructure, tungsten alloy technology, applied in the field of material science, to achieve the effect of simple preparation method, excellent strength and high temperature stability, and improve the strength of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a kind of double nanostructure tungsten alloy, and its preparation method comprises the following steps:

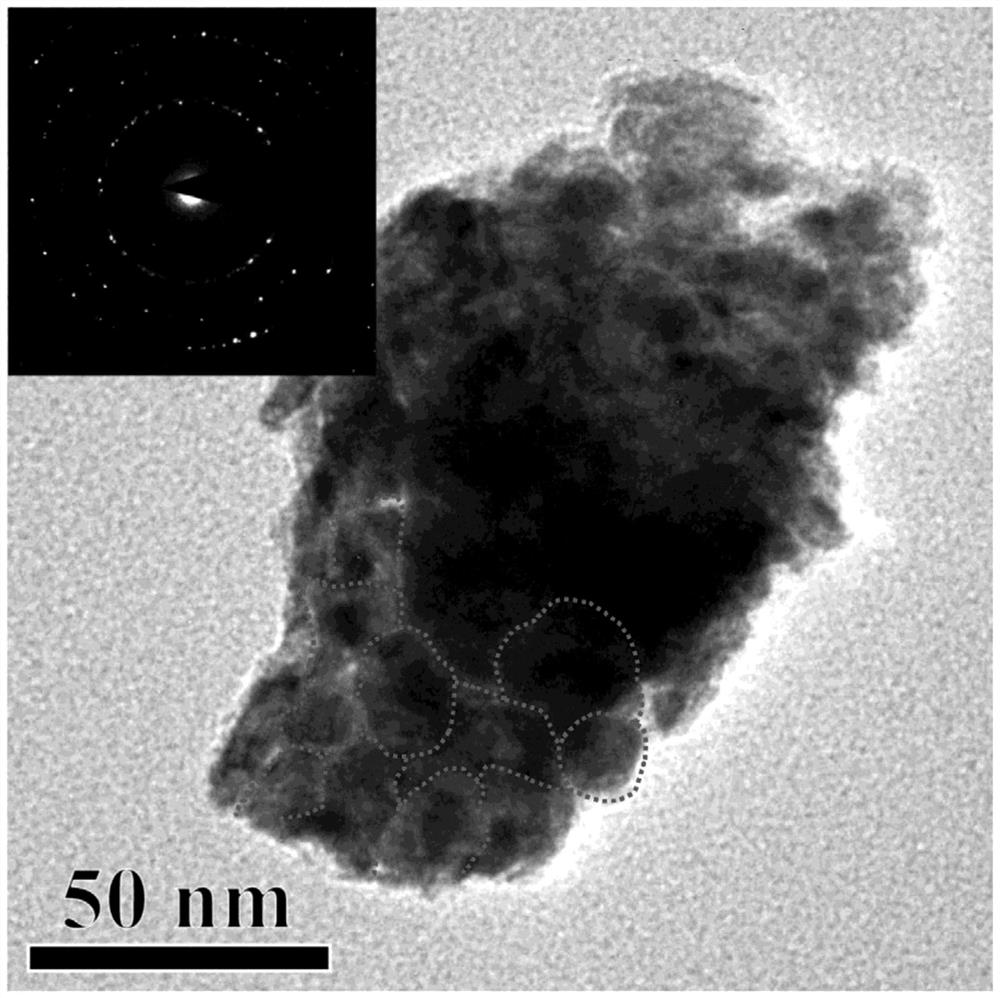

[0048] (1) Weigh and mix tungsten powder, titanium powder and zirconium carbide powder according to the mass percentage of 98.5%, 1.0% and 0.5% respectively, and place them in an argon atmosphere for ball milling to achieve alloying and nanocrystallization , the rotating speed of ball milling is 600r / min, and the time of ball milling is 48h, obtains nanocrystalline alloy powder; The transmission electron microscope (TEM) figure of this nanocrystalline alloy powder is as follows figure 1 shown;

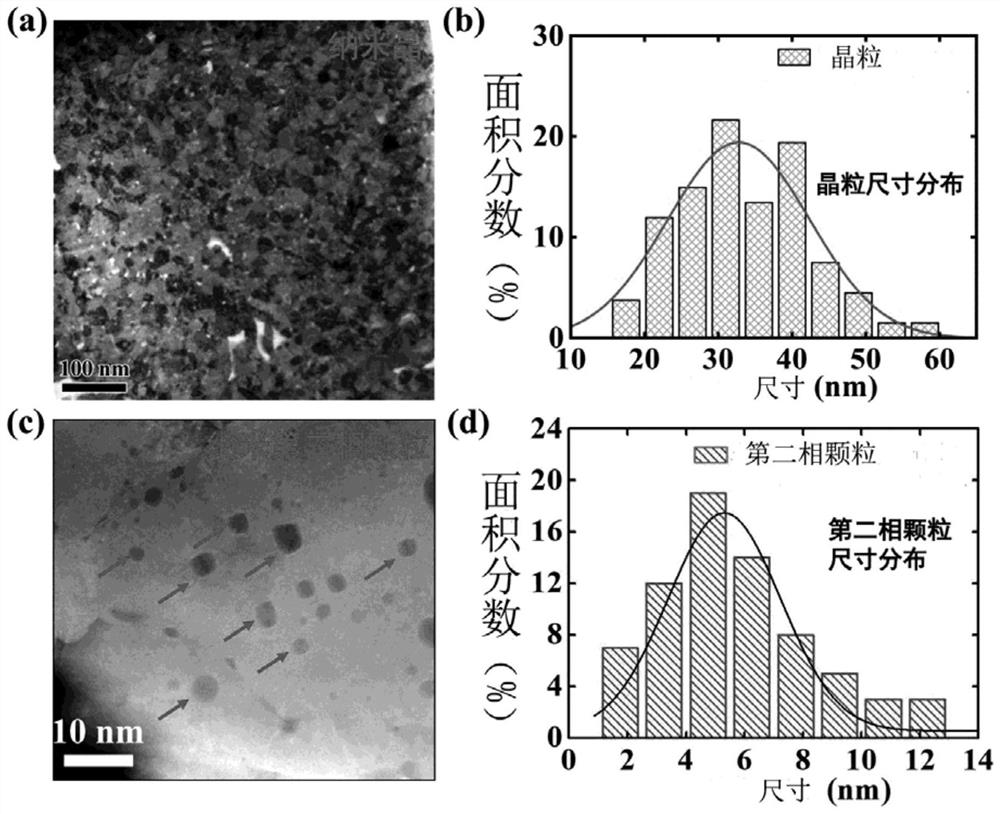

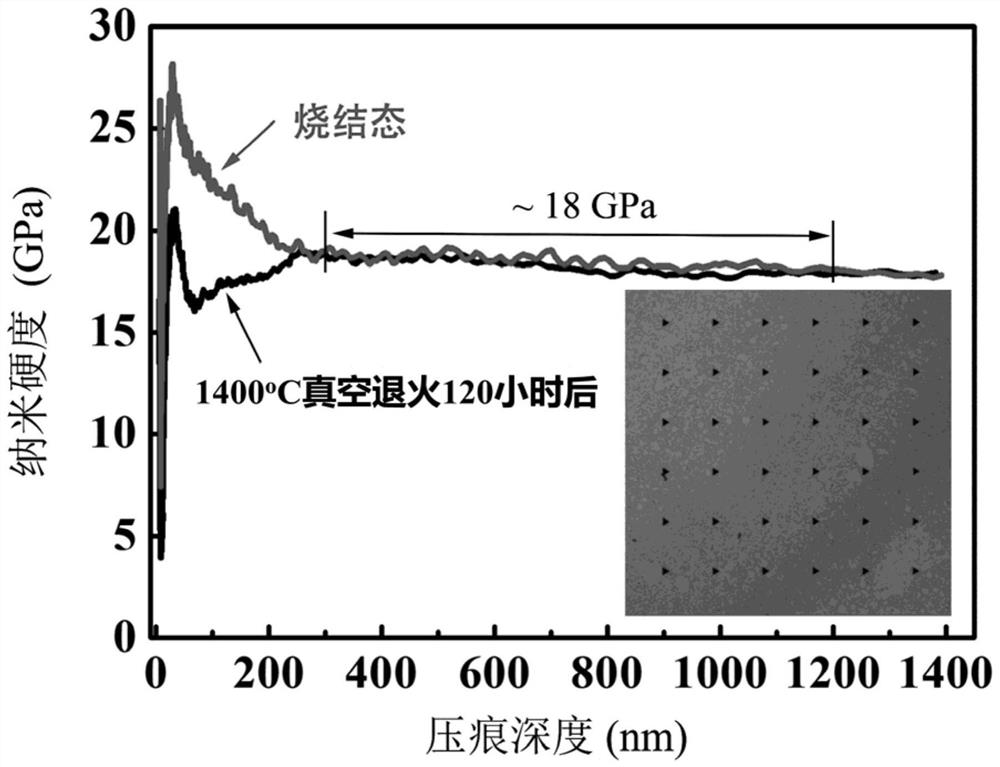

[0049] (2) Place the nanocrystalline alloy powder obtained in step (1) in a die set (mold), and then place it together with the die set (mold) in a dry and flowing argon atmosphere, and then place it in a spark plasma sintering process. Sinter in a furnace at a temperature of 1400°C and a pressure of 50 MPa for 40 minutes to obtain a dense alloy bl...

Embodiment 2

[0053] This embodiment provides a kind of double nanostructure tungsten alloy, and its preparation method comprises the following steps:

[0054] (1) Weigh and mix tungsten powder, titanium powder and zirconium carbide powder according to the proportions of 97%, 2.0% and 1.0% by mass respectively, and place them in a vacuum environment <10Pa for ball milling to achieve alloying and nano Crystallization, the speed of ball milling is 450r / min, and the time of ball milling is 60h to obtain nanocrystalline alloy powder;

[0055] (2) Place the nanocrystalline alloy powder obtained in step (1) in a die set (mold), and then place it together with the die set (mold) in a dry and flowing argon atmosphere, and then place it in a spark plasma sintering process. Sinter in a furnace at a temperature of 1600°C and a pressure of 60 MPa for 30 minutes to obtain a dense alloy block (the density of the alloy block is higher than 96%, and the block has no cracks), which is a double nanostructure...

Embodiment 3

[0058] This embodiment provides a kind of double nanostructure tungsten alloy, and its preparation method comprises the following steps:

[0059] (1) Weigh and mix tungsten powder, titanium powder and zirconium carbide powder according to the mass percentage of 98.5%, 1.0% and 0.5% respectively, and place them in an argon atmosphere for ball milling to achieve alloying and nanocrystallization , the rotating speed of ball milling is 300r / min, the time of ball milling is 72h, and nanocrystalline alloy powder is obtained;

[0060] (2) Place the nanocrystalline alloy powder obtained in step (1) in a mold cover (mould), and then place it together with the mold cover (mould) in a dry and flowing argon atmosphere. Sintering at a temperature of 1400°C and a pressure of 50 MPa for 40 minutes to obtain a dense alloy block (the density of the alloy block is higher than 96%, and the block has no cracks), which is a double nanostructure tungsten alloy.

[0061] The double nanostructure tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com