Electric spark assisted ultrasonic vibration turning combined machining equipment and method

A technology of ultrasonic vibration and combined processing, which is applied in the field of turning processing, and can solve problems such as low processing efficiency, poor processing surface quality, and large wear of turning tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The present application will be further described in conjunction with the accompanying drawings in conjunction with the accompanying drawings.

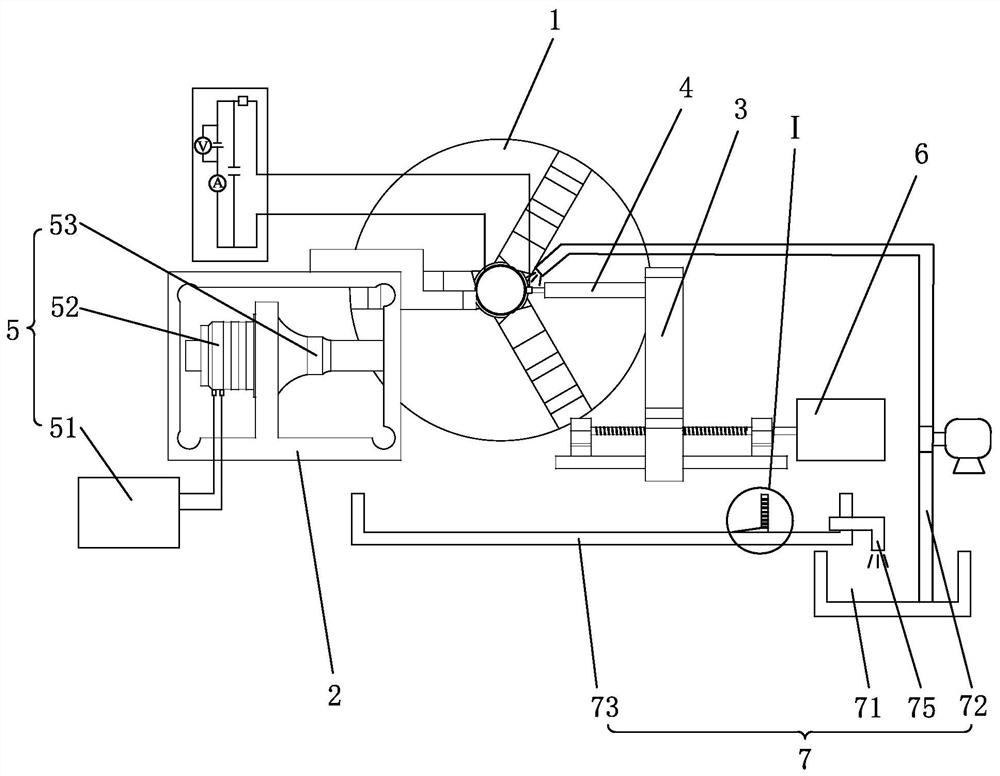

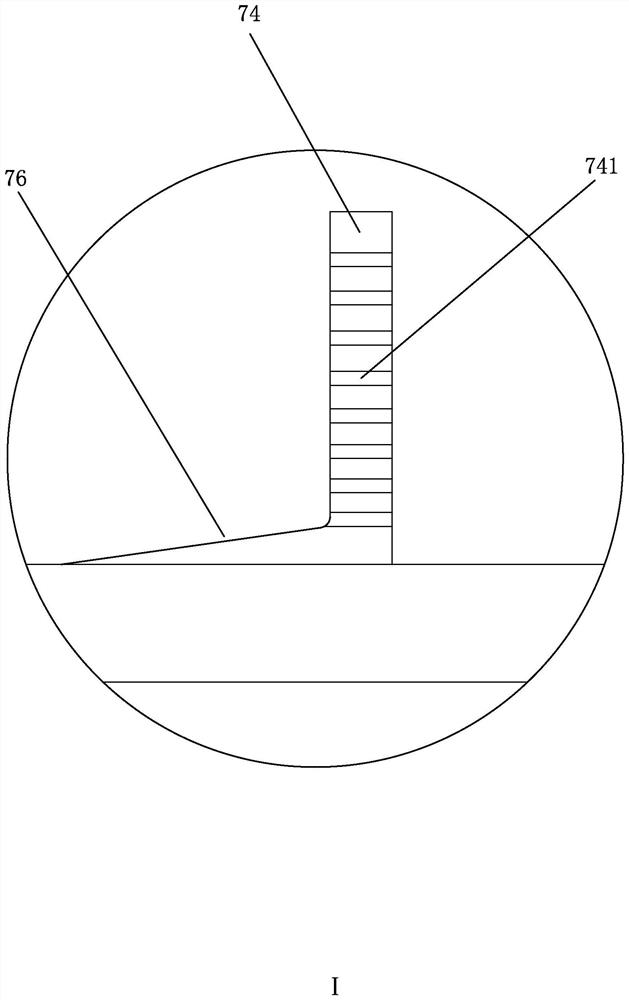

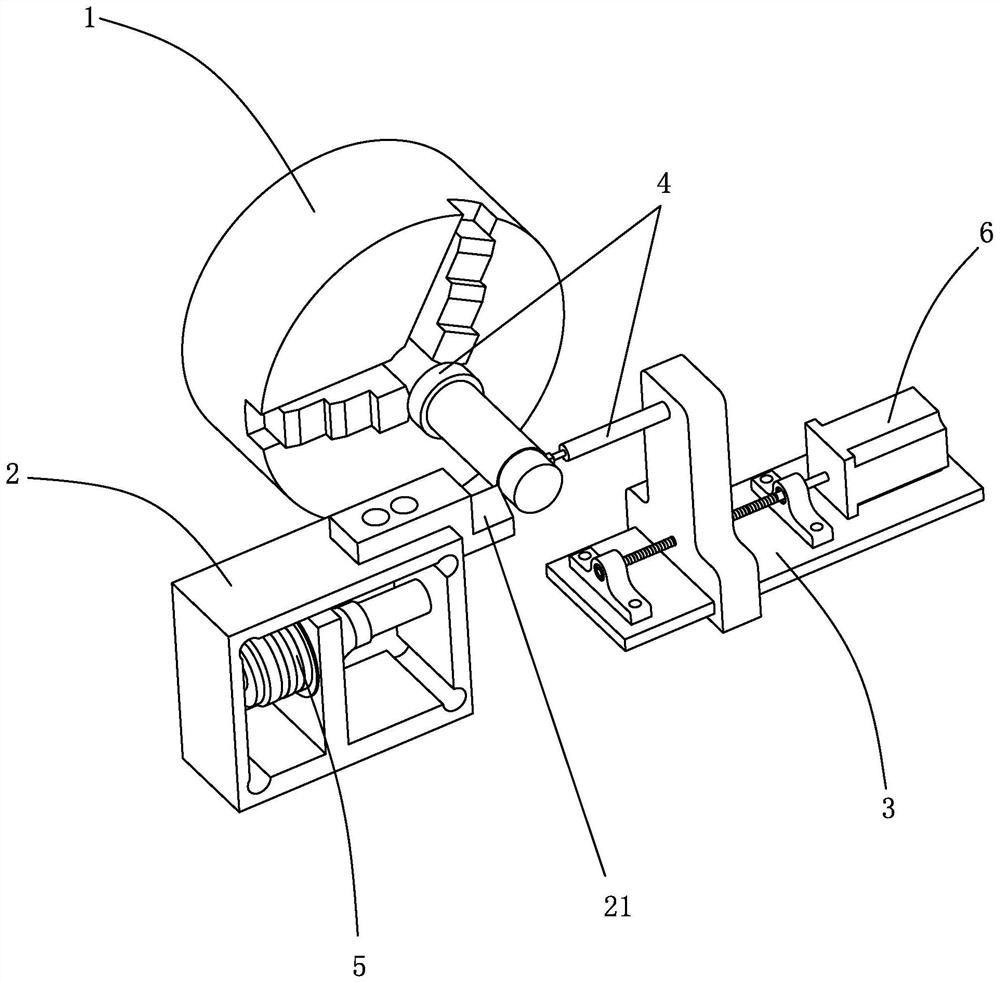

[0049]Such asFigure 1 ~ 8As shown, an electro-fire-assisted ultrasonic vibrating vehicle cutting process, including machine tools, chuck 1, moving turning device 2, mounting bracket 3, discharge heating device 4, ultrasonic generating device 5.

[0050]Specifically, the chuck 1 is disposed on the machine for a clip workpiece; the moving turning device 2 is provided on the upper side of the machine and is used for mobile vehicle cutting parts; the mobile turning device 2 There is a tool 21 for turning workpieces; the mounting bracket 3 is disposed on the other side of the machine, and is connected to the moving turning device 2, which is moved from the moving turning device 2; the discharge heating The device 4 is provided on the mounting bracket 3 for energizing to discharging the heating workpiece; the ultrasonic generating device 5 is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com