Closed underground brine mining system and construction method thereof

An underground brine, closed technology, applied in the direction of mining fluid, earth drilling, sealing/isolation, etc., can solve the problems of low permeability, less brine extraction, and difficulty in meeting actual production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

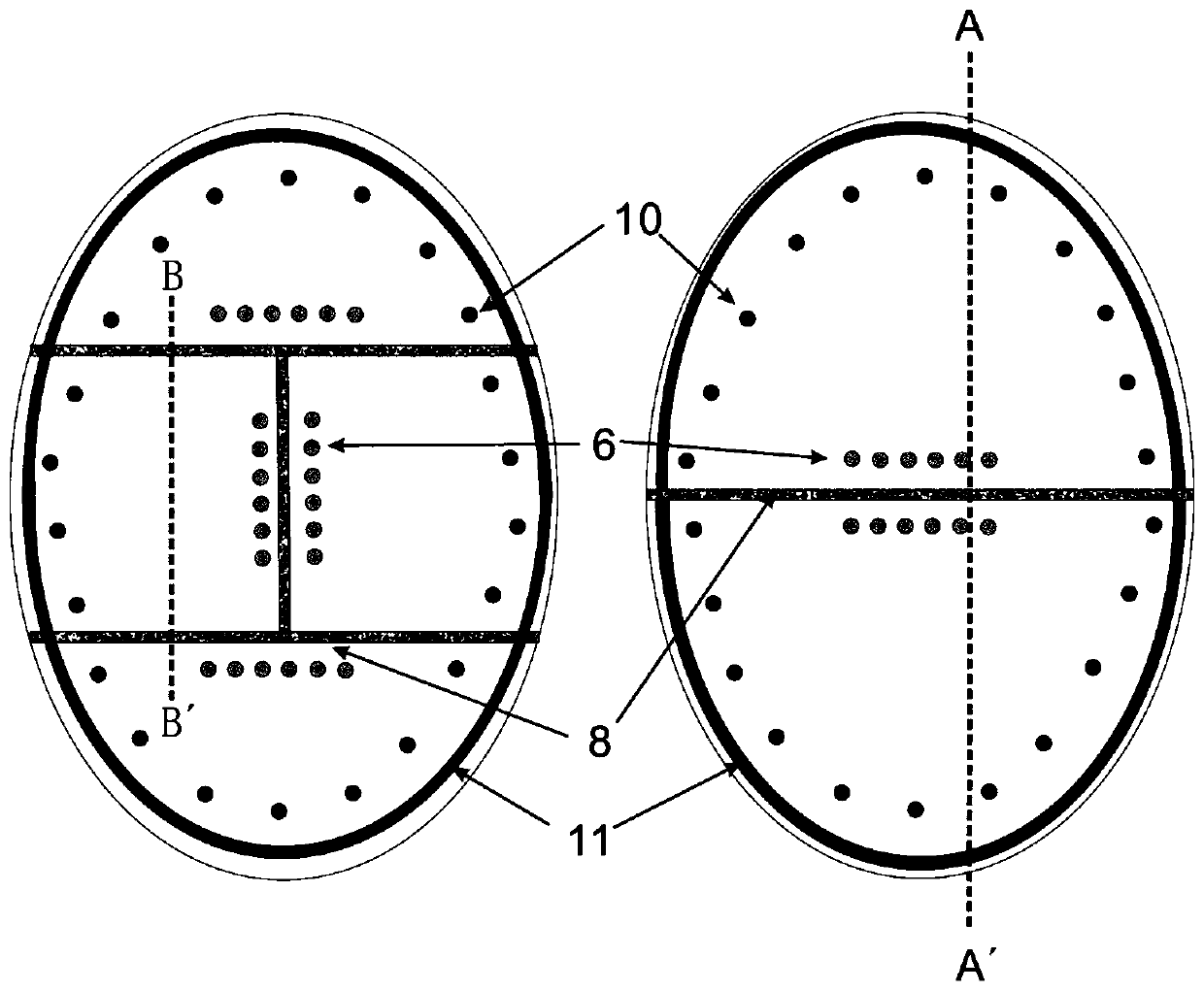

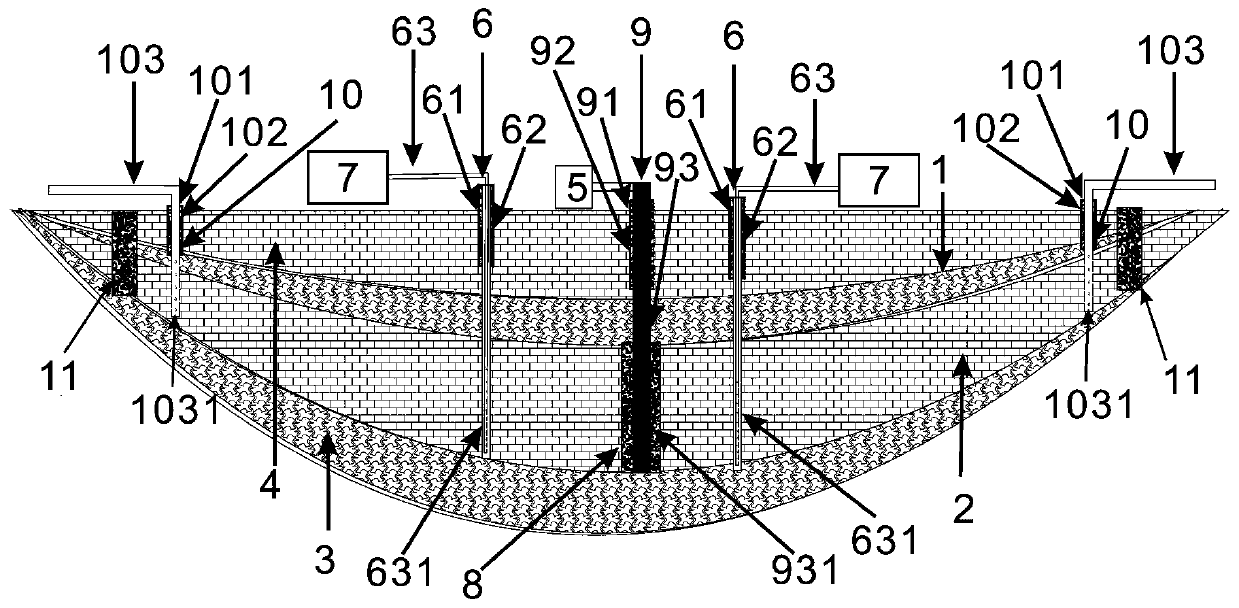

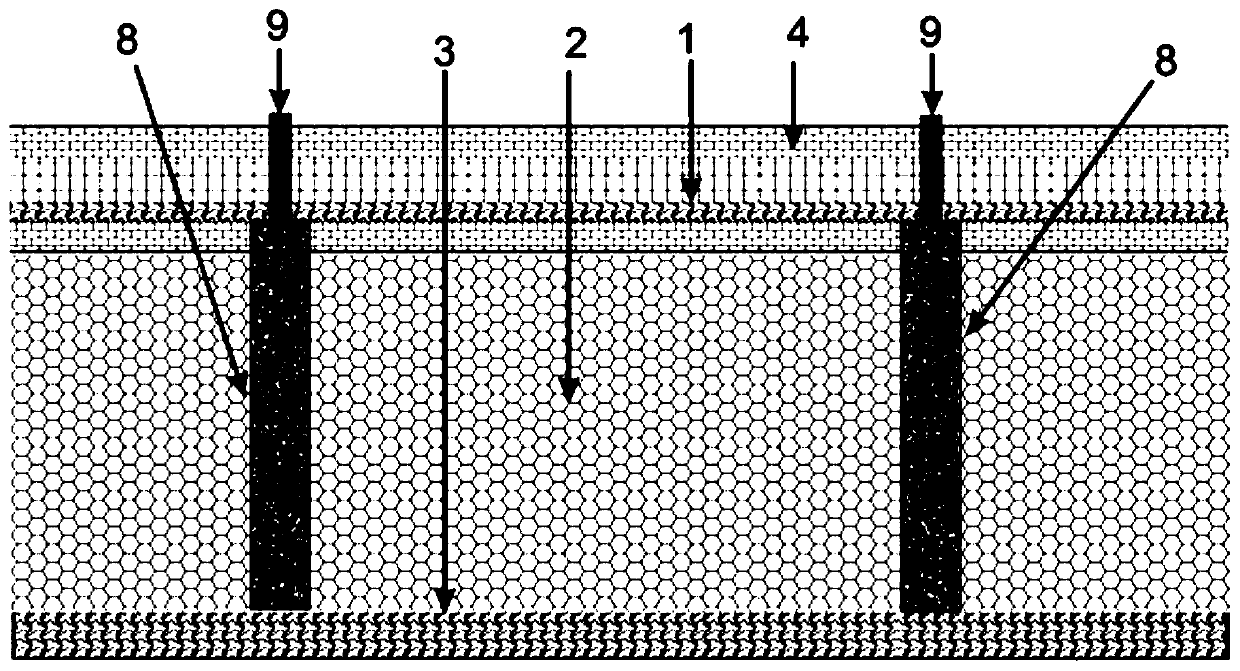

[0026] see in conjunction Figure 1 to Figure 4As shown, it is an overall schematic diagram of the salt lake closed underground brine mining system according to the embodiment of the present invention.

[0027] see figure 1 , is a schematic plan view of the in-line and H-shaped brine mining blocks in the closed underground brine mining system of the embodiment of the present invention. For the brine storage layer located between two or more natural sedimentary water-resisting layers in the salt lake, the system uses artificial drilling curtains, rotary excavation and rotary spraying to form a separation wall 8, and a water-resisting dam 11 filled with slots , separating and trapping the brine storage layer between the first water-resisting layer and the second water-resisting layer, arranging gas compression wells 6 near the center of the lake in these closed spaces, and arranging brine discharge wells 10 near the edge of the lake; Simultaneously, the center position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com