High section trend wall-type fully mechanized caving mining method for large inclined super high seam

A kind of extra-thick coal seam and wall-oriented technology, which is applied in special mining, ground mining, earthwork drilling and mining, etc., can solve the problems of low safety factor, difficult mining, and inability to achieve efficient mining, so as to alleviate the fall and reduce the Mining difficulty and the effect of reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

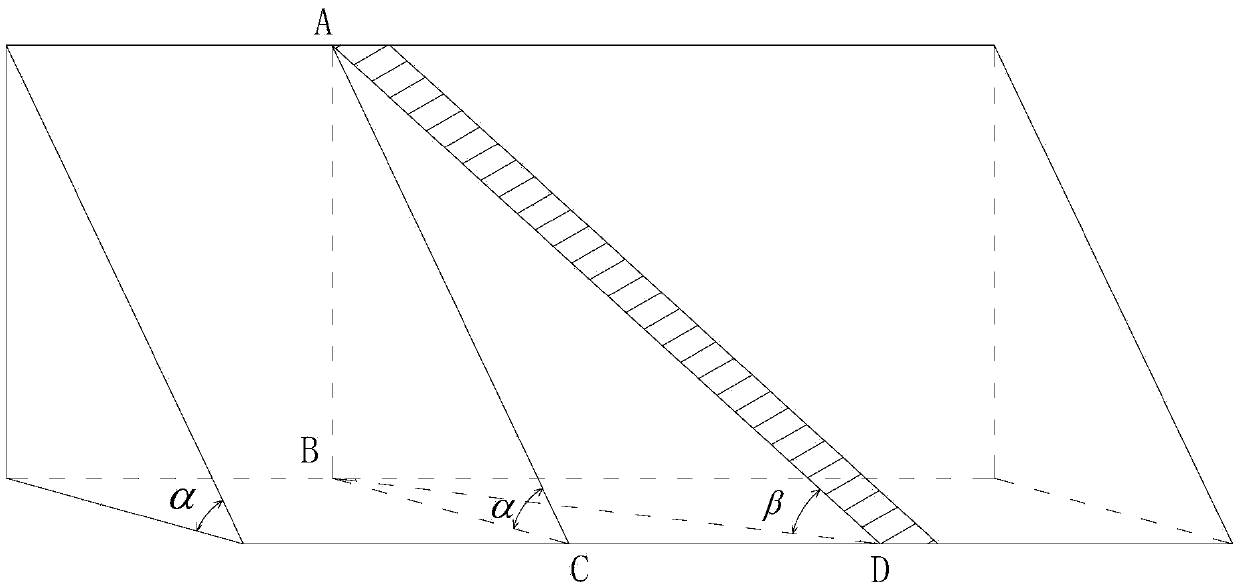

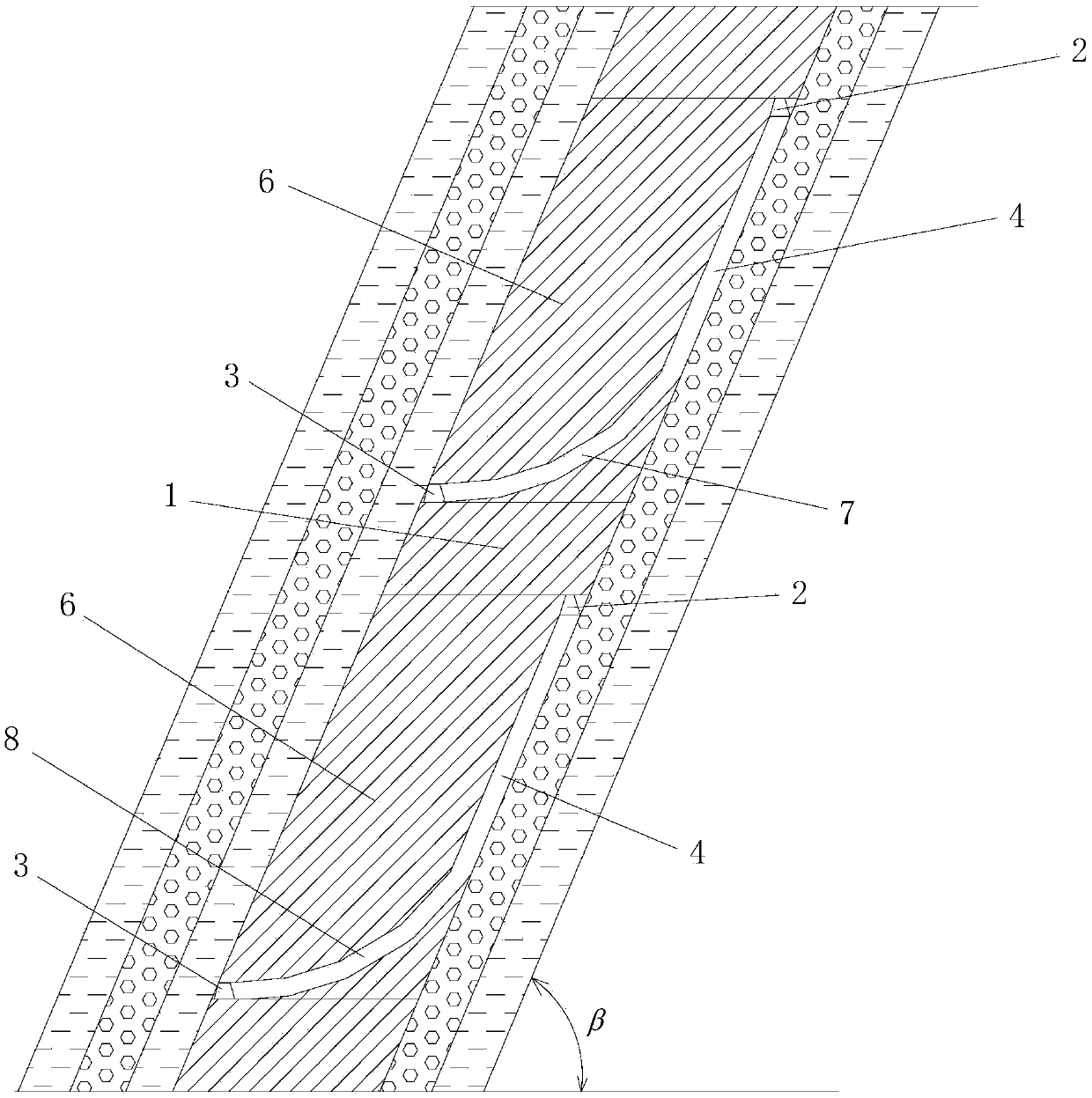

[0052] Such as figure 1 Shown is a fully mechanized caving coal mining method in the high section of a large-inclined and extra-thick coal seam, in which a plurality of coal mining sections are arranged from top to bottom in the same stage of the mined large-inclined and extra-thick coal seam 6, two adjacent up and down. Section protection coal pillars 1 for protection or isolation are left between the two coal mining sections, and the upper and lower parts of each of the coal mining sections are respectively provided with return air along the coal seam direction of the large inclined ultra-thick coal seam 6 Level 2 and transport level 3, see details image 3 and Figure 4 The coal mining face structure of a plurality of described coal mining sections is all identical and its section height H is all identical, and the section height H of described coal mining section is the vertical height of this coal mining section; When the coal seam 6 is mined, a plurality of said coal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com