Ore drawing mining method for inclined layered solid ore deposit

A mining method and inclined layer technology, applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of heavy mining workload and low mining rate, and achieve reduced cost input, lower ore body hardness, and lower roof The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Embodiment A kind of ore-drawing and mining method of inclined layered solid ore deposit

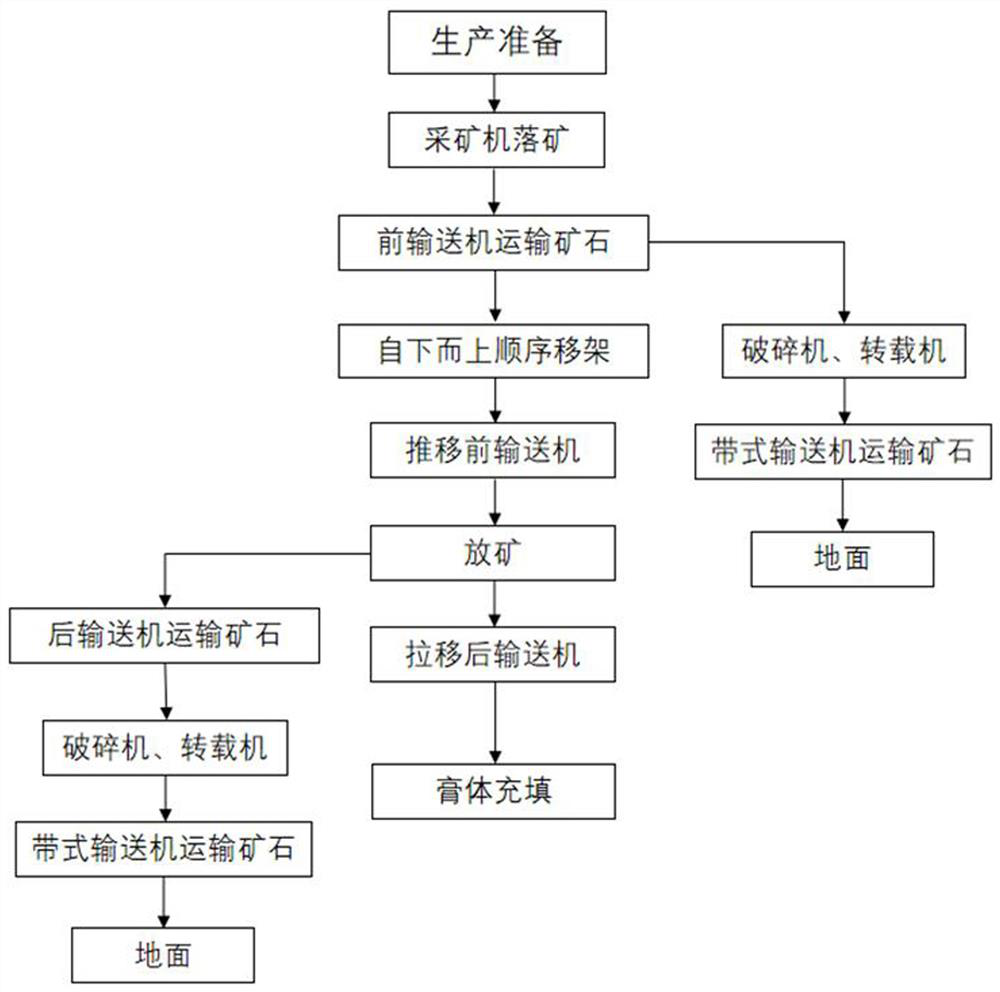

[0047] The ore-drawing mining method of the inclined layered solid deposit, the technical process can be found in figure 1 , including the following steps, in order:

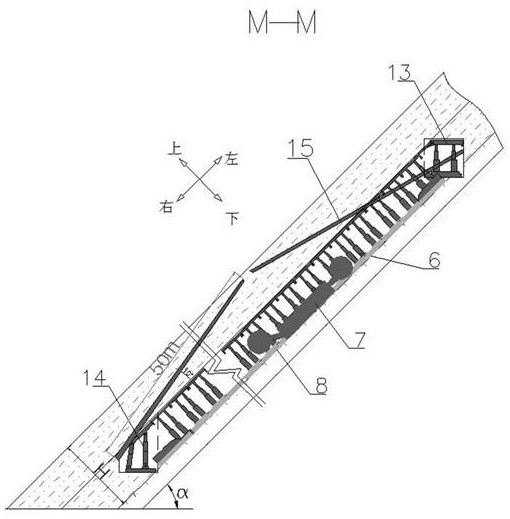

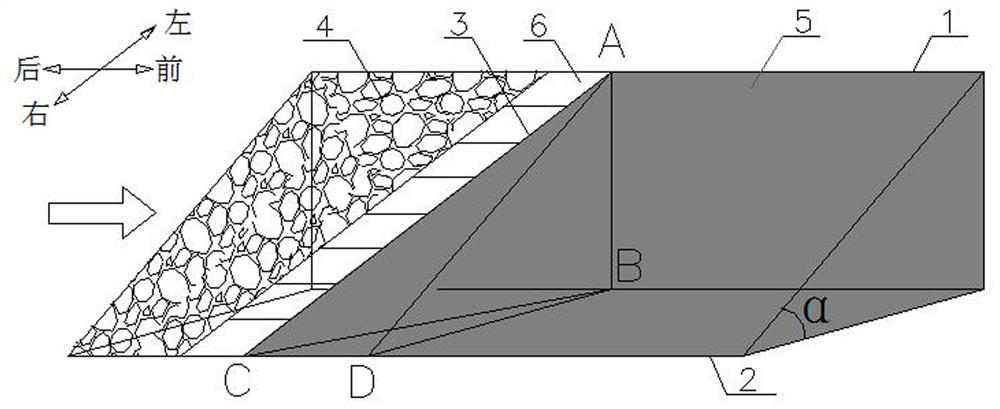

[0048] 1) Work surface layout

[0049]Select an inclined layered non-coal solid deposit with a dip angle of 35-65° and a thickness of 5-15 m (the ore body of the Jinning Phosphate Deposit in Kunming City, Yunnan Province has good continuity, the average thickness of the ore layer is 13.09 m, and the dip angle is 50° or so), refer to figure 2 and image 3 As shown in , taking the positional relationship between the two boundaries of the inclined ore body 5 parallel to the direction of the inclined ore body 5 and being close to the ground and away from the ground as left and right, the relative positional relationship between the inclined ore body 5 and the goaf 4 is Before and after, the return airway 1 is excav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com