Variable-stroke-frequency device of beam pumping unit

A beam-type pumping unit and stroke technology, which is applied to electromechanical devices, controlling mechanical energy, exploiting fluids, etc., can solve the problems of empty pumping, small adjustable range, and high cost of reducer, so as to ensure service life and reduce The effect of mining difficulty and reducing mining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

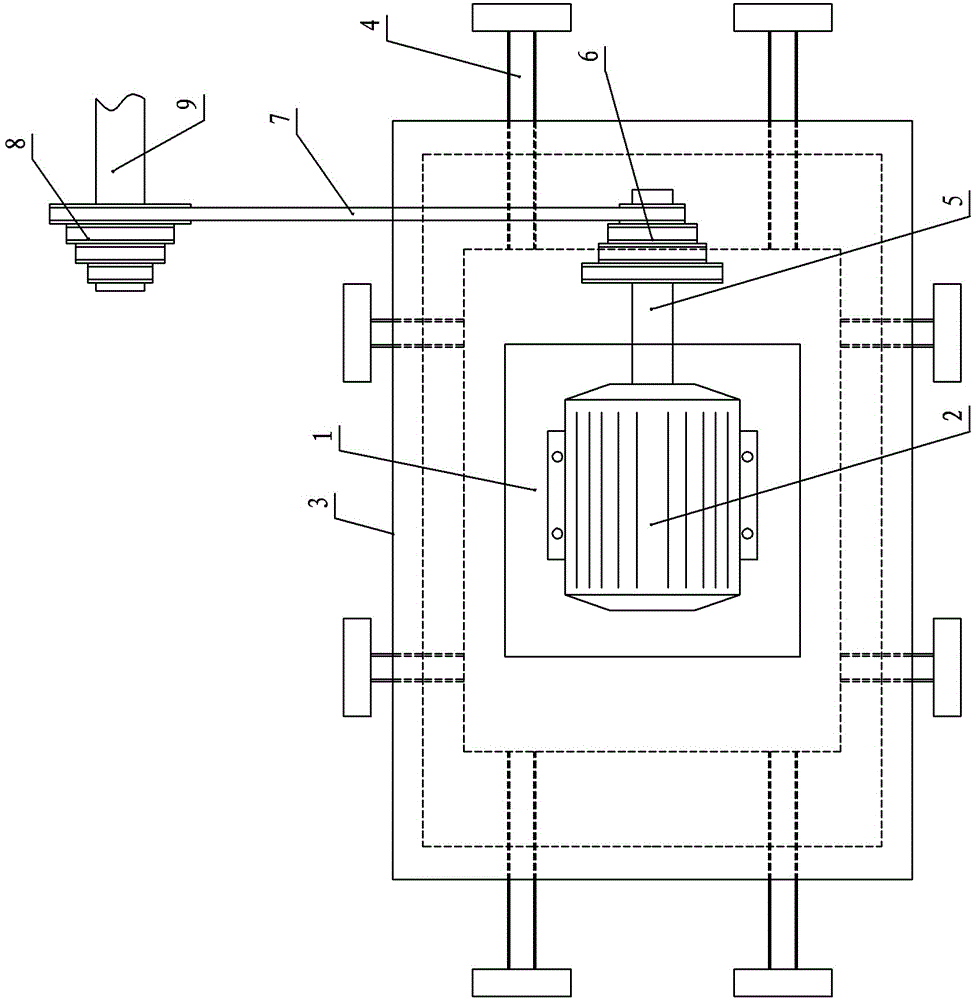

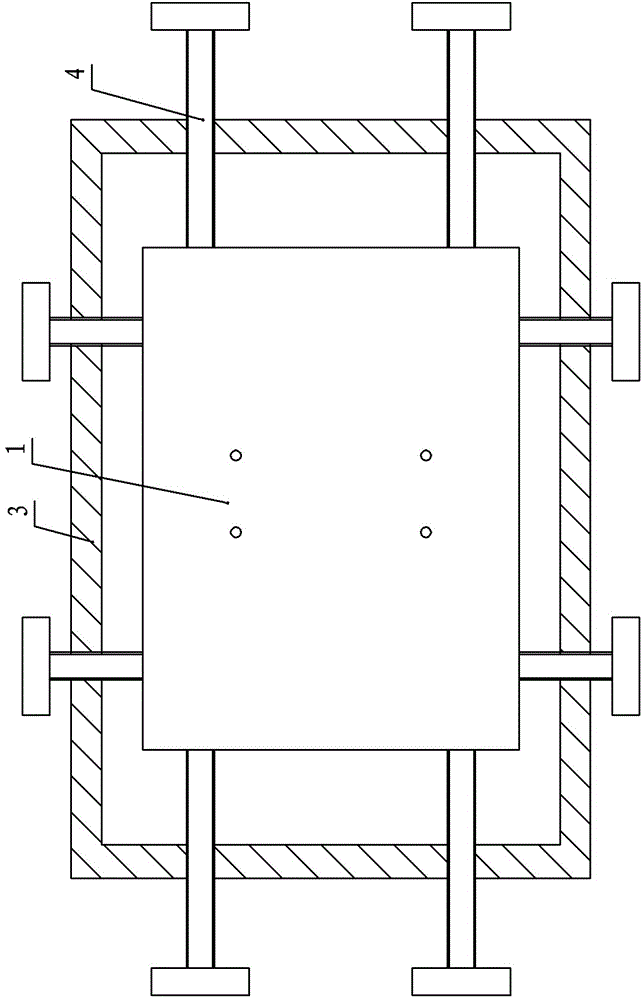

[0018] Example: see figure 1 In the figure, a beam-pumping unit variable stroke device includes a motor, a motor movable installation mechanism, and a double tower wheel output mechanism. The motor movable installation mechanism includes a square bottom plate connected to the motor, and a square bottom plate pressed on the top of the bottom plate. The frame plate is provided with a square opening in the middle of the frame plate. The length and width of the square opening are smaller than the length and width of the square base plate. The four edges of the frame plate of the square base plate are provided with folded edges, and top wires are installed on the folds, and the top wires pass through Installed over the flange and in contact with the edge of the square bottom plate, the motor is installed in the middle of the square bottom plate, and the motor shaft is connected with the transmission mechanism of the pumping unit through the output mechanism of the tower wheel.

[0...

Embodiment 2

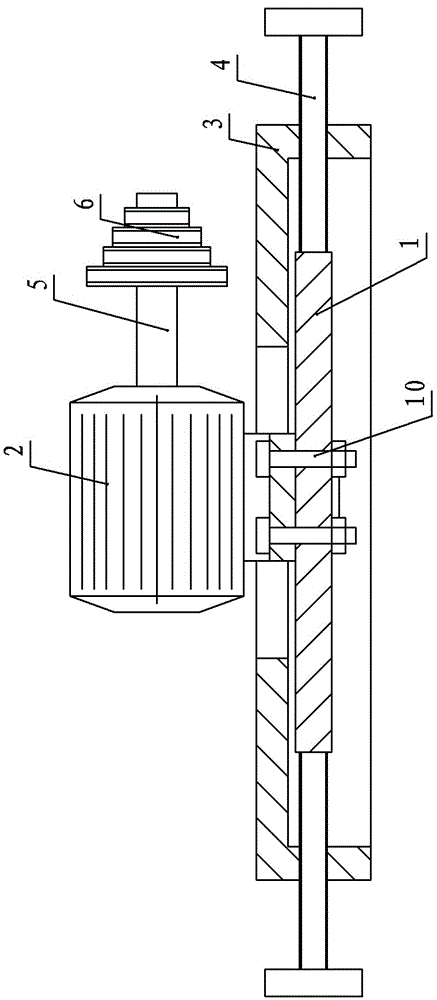

[0021] Embodiment two: see Figure 4 In the figure, a beam-pumping unit variable stroke device includes a motor, a motor movable installation mechanism, and a double tower wheel output mechanism. The motor movable installation mechanism includes a square bottom plate connected to the motor, and a square bottom plate pressed on the top of the bottom plate. The frame plate is provided with a square opening in the middle of the frame plate. The length and width of the square opening are smaller than the length and width of the square base plate. The four edges of the frame plate of the square base plate are provided with folded edges, and top wires are installed on the folds, and the top wires pass through Installed over the flange and in contact with the edge of the square bottom plate, the motor is installed in the middle of the square bottom plate, and the motor shaft is connected with the transmission mechanism of the pumping unit through the output mechanism of the tower whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com