Pulse thickened-oil exploiting device and method for exploiting thickened oil by pulses

A technology of pulse wave and heavy oil, which is applied in heavy oil exploitation engineering, pulse wave exploitation heavy oil device and pulse wave exploitation heavy oil field, which can solve the problems such as difficult maintenance, difficult development, difficult to guarantee recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

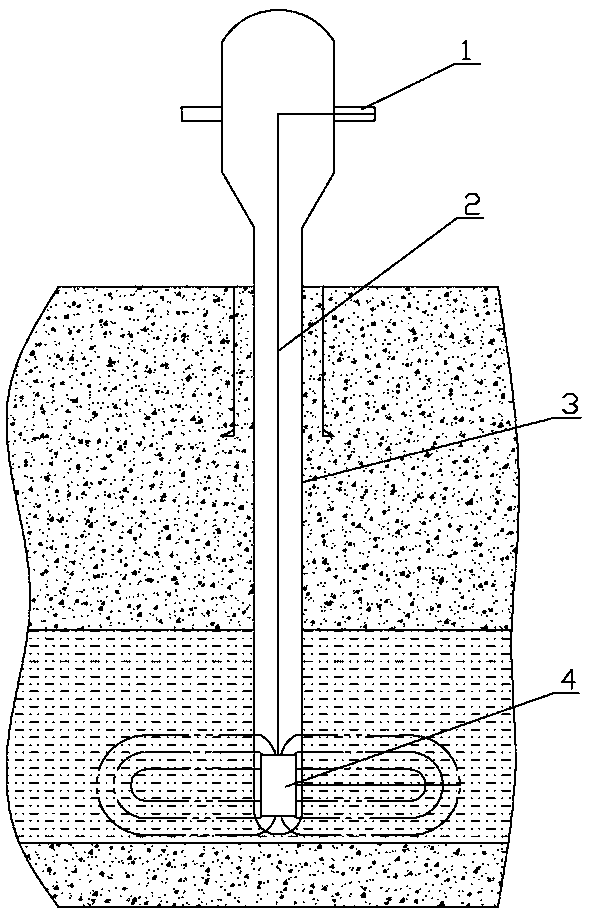

[0024] Embodiment 1, as attached figure 1 As shown, the pulse wave recovery heavy oil device includes a wellhead device 1, a transmission device 2, an oil layer string 3 and a flow conversion device 4; a wellhead device 1 capable of providing high-frequency pulse wave fluid and a transmission device 2 Located in the oil layer pipe string 3, the flow conversion device 4 is arranged at the bottom of the well, the outlet end of the wellhead device 1 is fixedly installed and communicated with the inlet end of the transmission device 2, and the outlet end of the transmission device 2 is connected to the inlet end of the flow conversion device 4 They are fixedly installed together and communicated with each other, and the diverter hole 9 for transmitting the pulse fluid to the oil layer is arranged on the flow diverter device 4 . The wellhead device 1 can generate high-frequency pulse wave fluid, and the high-frequency pulse wave fluid is transported to the flow-changing device 4 th...

Embodiment 2

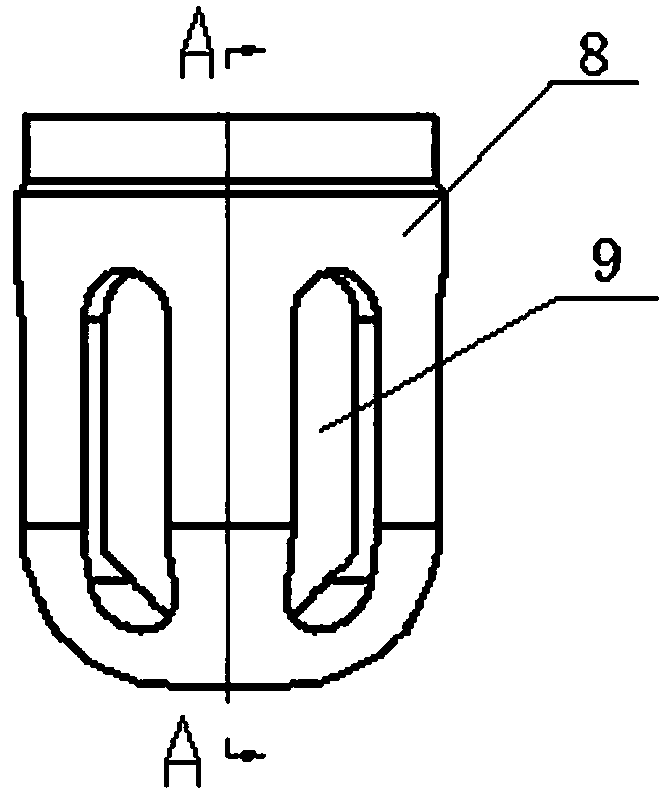

[0025] Embodiment 2, as the optimization of embodiment 1, as attached figure 1 , 2 , 3, and 4, the flow conversion device 4 includes a shunt short and more than two Helmholtz self-resonating cavity shorts, and more than two Helmholtz self-resonating cavity shorts are installed together up and down in sequence to form Helmholtz natural cavity short-circuit group, the lower end of the bottom Helmholtz natural cavity short-connector in the Helmholtz natural-resonant cavity short-circuit group is fixedly installed with the upper end of the shunt short-circuit; 3 can be a combination of casing strings and screen strings, the upper rock layer is a casing string, and the lower oil zone is a screen string; the flow conversion device 4 converts the high-frequency pulse wave fluid provided by the wellhead device 1 Low-frequency pulse fluid of heavy oil layers with different viscosities, and the low-frequency fluid pulse wave is transmitted to the oil layer through shunt short circuit. ...

Embodiment 3

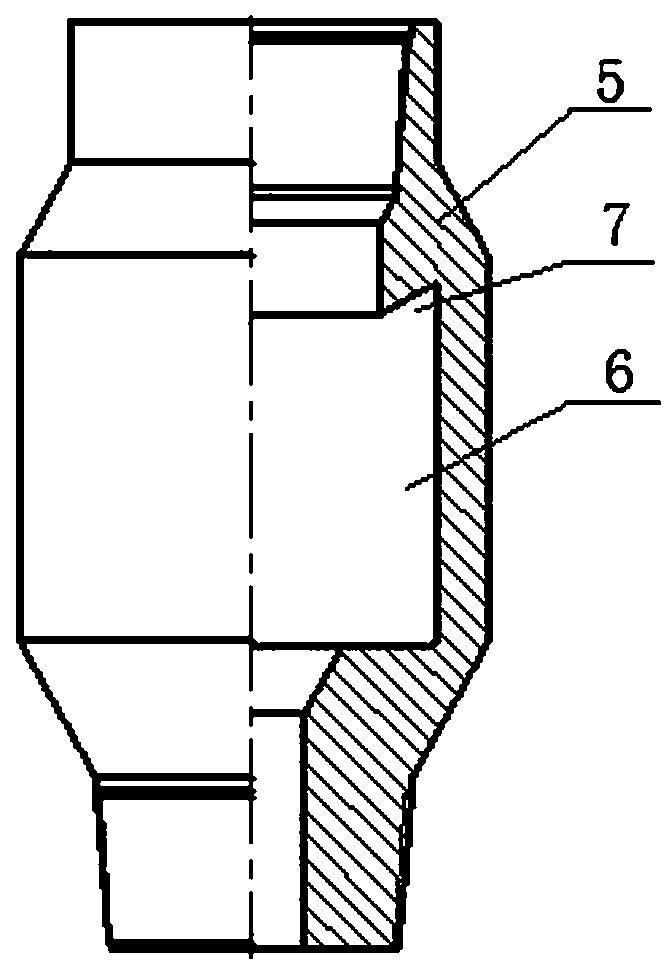

[0027] Embodiment 3, as the optimization of embodiment 2, as attached figure 2 As shown, the Helmholtz natural vibration cavity short circuit includes a tubular body 5, a natural vibration cavity 6 with an inner diameter larger than the inner diameter of the body 5 is arranged on the inner wall of the body 5, and a dovetail groove 7 is arranged on the upper wall of the natural vibration cavity 6 . Due to its unique internal structure, the Helmholtz natural cavity short circuit in the variable flow device 4 can transform the high-frequency pulsed fluid provided by the wellhead device 1 into a low-frequency pulsed fluid suitable for heavy oil reservoirs with different viscosities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com