FRP pipe composite bar sea sand concrete column and preparation method thereof

A composite reinforced concrete and composite reinforced technology, which is applied in the fields of port and island engineering, bridge engineering, and structural engineering, can solve the problems of FRP reinforced non-compressive, sudden damage, etc. Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

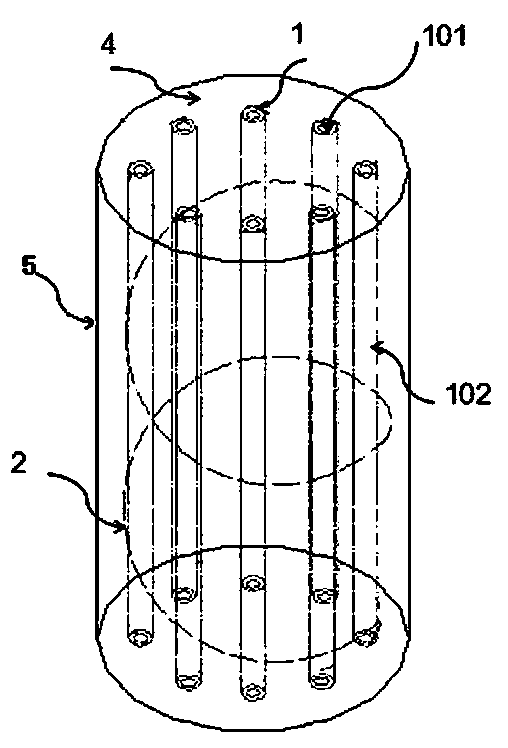

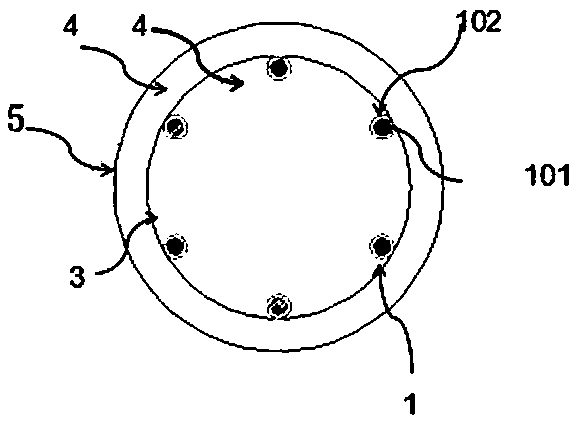

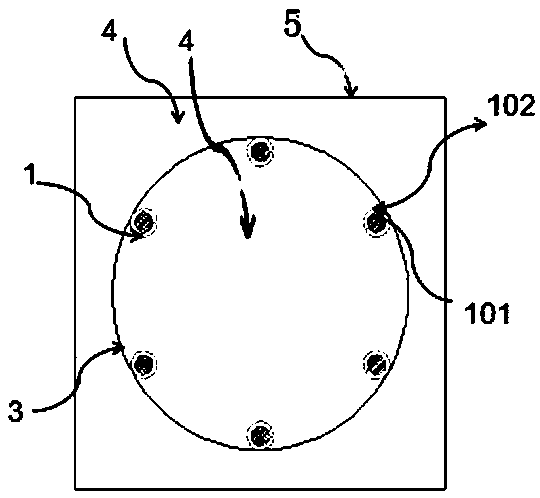

[0065] A kind of FRP pipe composite bar sea sand concrete column, such as Figure 1 to Figure 3 As shown, it includes FRP-steel composite reinforcement cage, FRP pipe 5 sleeved outside the FRP-steel composite reinforcement cage, and concrete 4 filled in the FRP-steel composite reinforcement cage and between the outer FRP pipe 5; FRP - The steel composite reinforcement cage is formed by the FRP-steel composite reinforcement 1 and the spiral stirrup 2 surrounding the outside of the FRP-steel composite reinforcement 1 .

[0066] The hoop constraint force provided by the outer FRP pipe 5 not only significantly improves the bearing capacity of the concrete column, but also ensures the anti-corrosion performance of the overall structure of the concrete column. The FRP-steel composite bar 1 and the spiral stirrup 2 surrounding the FRP-steel composite bar 1 form an FRP-steel composite reinforcement cage skeleton. The FRP pipe 5 is a GFRP pipe. The FRP pipe 5 can be in the shape of a...

Embodiment 2

[0072] Such as Figure 5 As shown, in order to further enhance the comprehensive performance of the FRP pipe composite reinforced concrete column, on the basis of Example 1, in the FRP-steel composite cage, the upper and lower ends of the FRP-steel composite reinforcement 1 are provided with reinforcement stirrups 3, so as to Further improve the restrained longitudinal force of the FRP pipe composite reinforced sea-sand concrete column, and further improve the compressive bearing capacity of the concrete in the core area.

Embodiment 3

[0074] The preparation method of the FRP pipe composite reinforcement sea-sand concrete column of embodiment 1 may further comprise the steps:

[0075] S1. Apply adhesive epoxy resin on the outer surface of the steel bar. The thickness of the adhesive is 0.5 mm. The fully impregnated fibers are drawn from the resin tank to wrap the entire steel bar to form an FRP fiber layer, which is passed through a pultrusion die, and then Straighten through a stretching machine so that the direction of the fiber is consistent with the direction of the steel bar, and then the fiber is spirally wound, bonded with sand, and left to stand to obtain the FRP-steel composite bar.

[0076] S2. According to the size of the specific column and the requirements of bearing capacity, select the FRP-steel composite bar with the corresponding diameter, bind it with a FRP spiral steel bar or a spiral steel bar wrapped with fiber cloth to form an FRP-steel composite reinforcement cage, and position the FRP-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com